Quenched and tempered gray cast iron, gray cast iron quenched and tempered method and its application

A gray cast iron, quenching and tempering technology, applied in the field of gray cast iron heat treatment, can solve the problems of easy cracking, loss of mechanical properties, etc., achieve high economic efficiency, prolong thermal fatigue life, and reduce the wall thickness of the cylinder head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

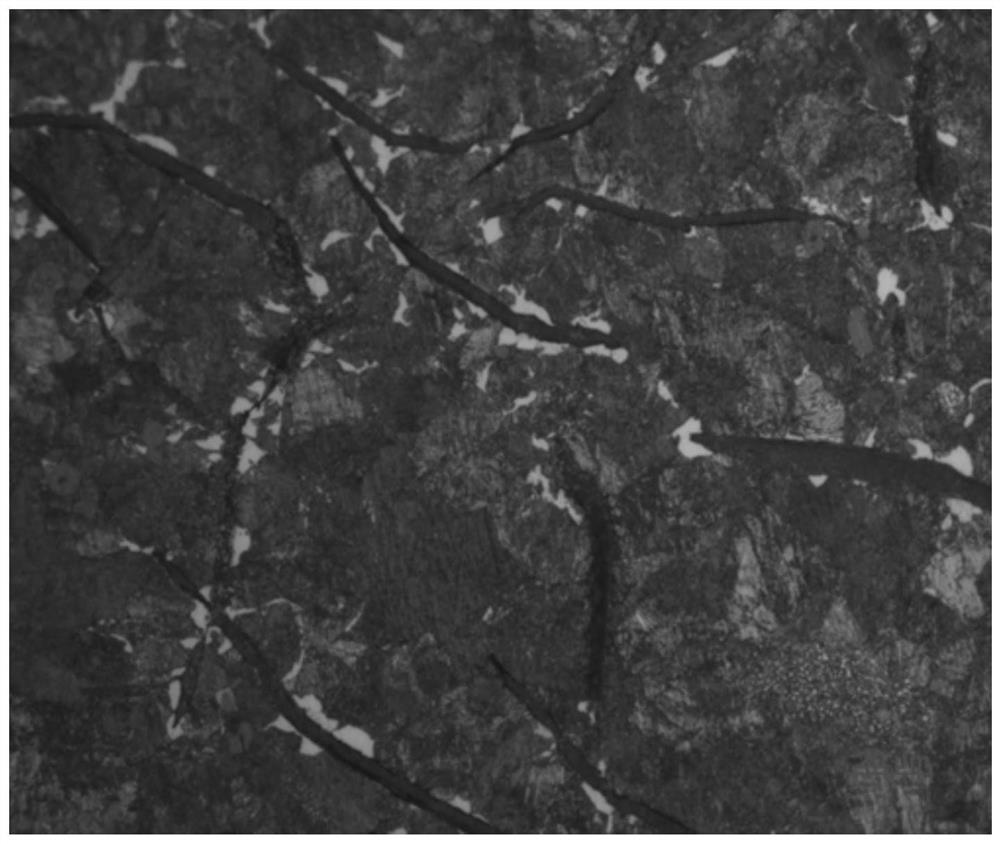

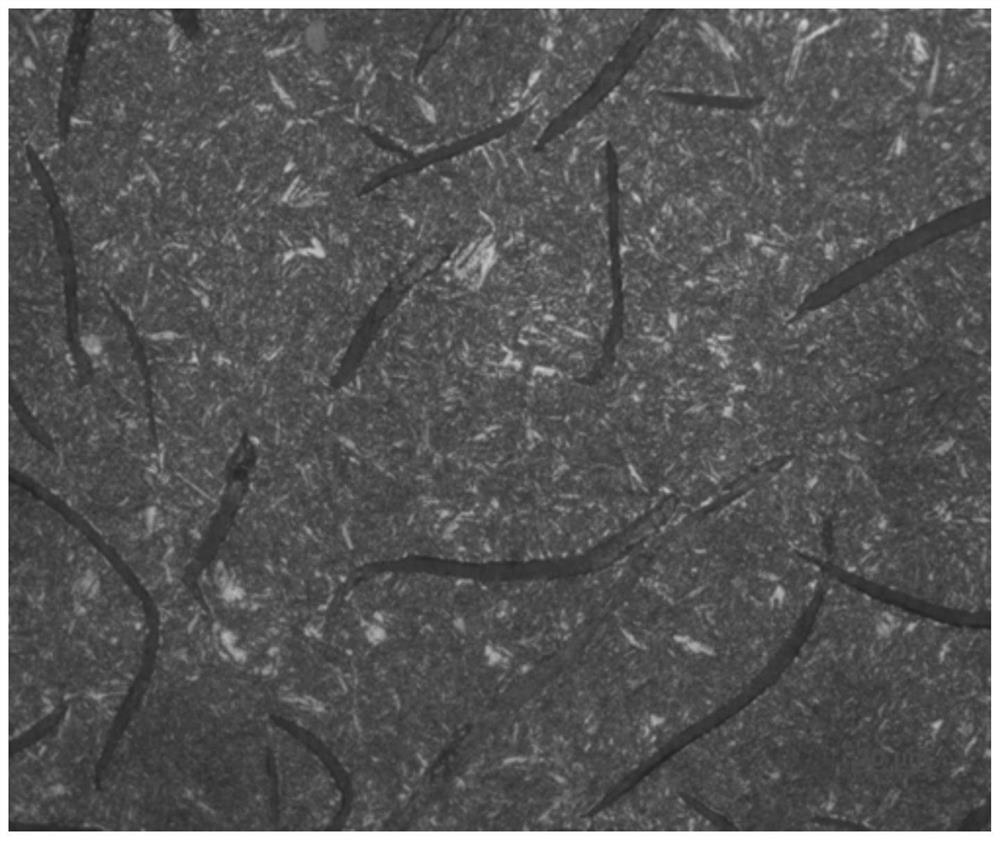

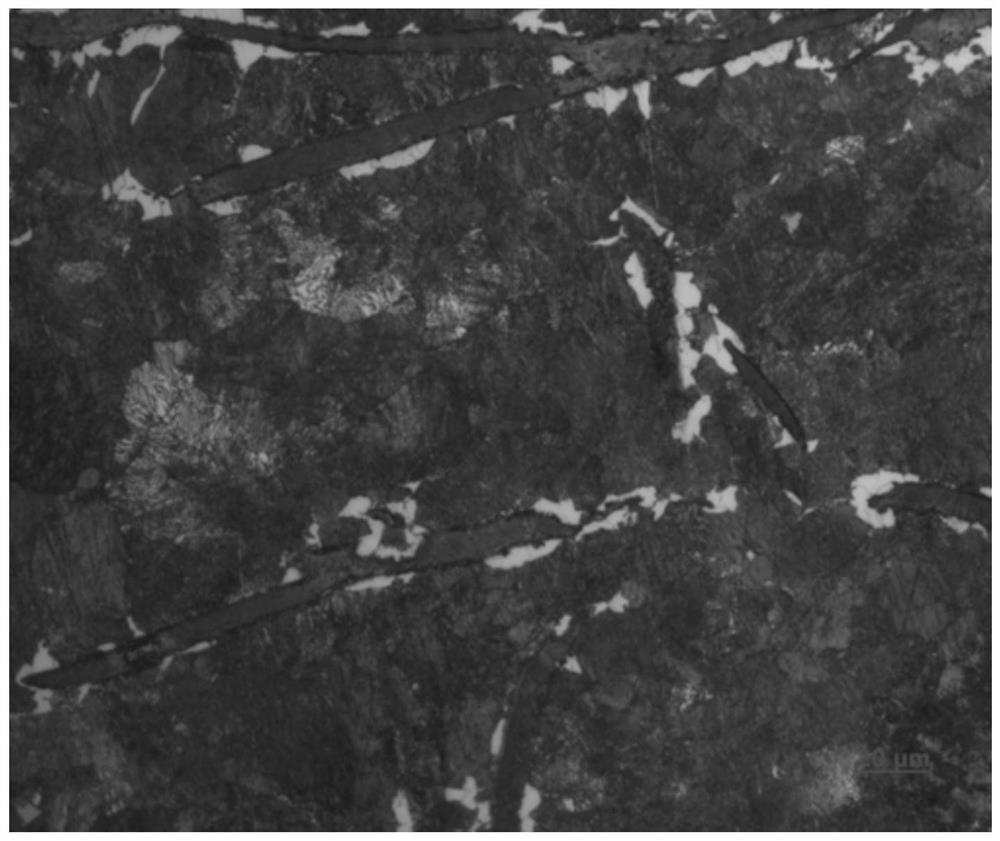

Image

Examples

Embodiment 1

[0047] The present embodiment provides the preparation method of quenched and tempered HT250 cylinder head, comprises the following steps:

[0048] (1) Casting: use the existing sand mold to cast the raw material into a cylinder head blank, the thickness of the cylinder head blank is 14mm, and the weight percentage of each chemical component in the raw material is: C: 3.18, Si: 1.91, Mn: 0.73, S: 0.078, P: 0.017, Cu: 0.50, Cr: 0.16, Ni: 0.15, Mo: 0.15; others are unavoidable impurities and Fe.

[0049] (2) Quenching treatment: Put the cast qualified cylinder head blank into a heating furnace and heat it to 890°C, keep it warm for 2 hours, and then quickly transfer it to the quenching oil tank for quenching treatment after being released from the furnace. The external cooling temperature is controlled, and the oil temperature is controlled at 85°C. Take it out after 5 minutes into the oil, and let it stand at room temperature for about 30 minutes. Turn over 3 times during this...

Embodiment 2

[0054] The present embodiment provides the preparation method of quenched and tempered HT250 cylinder head, comprises the following steps:

[0055] (1) Casting: use the existing sand mold to cast the raw material into a cylinder head blank, the thickness of the cylinder head blank is 14mm, and the weight percentage of each chemical component in the raw material is: C: 3.18, Si: 1.91, Mn: 0.73, S: 0.078, P: 0.017, Cu: 0.50, Cr: 0.16, Ni: 0.25, Mo: 0.15; others are unavoidable impurities and Fe.

[0056] (2) Quenching treatment: Put the cast qualified cylinder head blank into the heating furnace and heat it to 890°C, keep it warm for 1.5h, and then quickly transfer it to the quenching oil tank for quenching treatment after being released from the furnace. The oil temperature is controlled at 85°C, and the oil is added for 5 minutes Then take it out, and let it stand at room temperature for about 30 minutes, during which time it is turned over 3 times to remove the quenching oil ...

Embodiment 3

[0061] The present embodiment provides the preparation method of quenched and tempered HT250 cylinder head, comprises the following steps:

[0062] (1) Casting: use the existing sand mold to cast the raw material into a cylinder head blank, the thickness of the cylinder head blank is 14mm, and the weight percentage of each chemical component in the raw material is: C: 3.18, Si: 1.91, Mn: 0.73, S: 0.078, P: 0.017, Cu: 0.50, Cr: 0.16, Ni: 0.10, Mo: 0.15; others are unavoidable impurities and Fe.

[0063] (2) Quenching treatment: Put the cast qualified cylinder head blank into the heating furnace and heat it to 910°C, keep it warm for 1.5h, and quickly transfer it to the quenching oil tank for quenching treatment after it comes out of the furnace. The oil temperature is controlled at 85°C, and the oil is added for 5 minutes Then take it out, and let it stand at room temperature for about 30 minutes, during which time it is turned over 3 times to remove the quenching oil inside th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com