High thermal fatigue resistant commercial vehicle brake disc material and preparation method thereof

A technology for brake discs and commercial vehicles, which is applied in the automotive field and can solve problems such as low service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

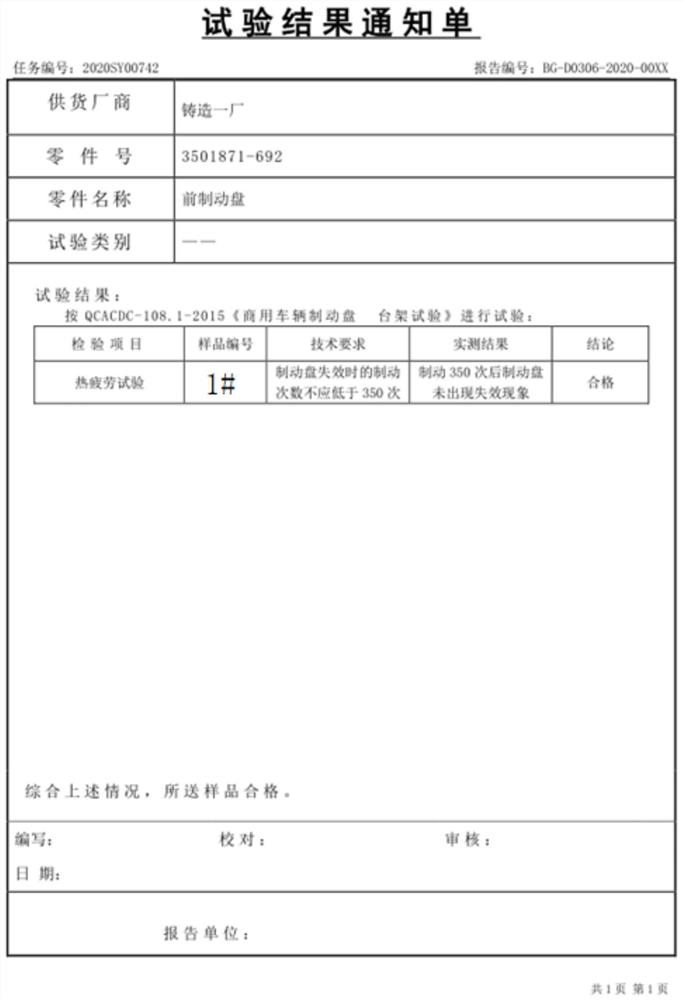

Image

Examples

Embodiment 1

[0041] Take 61% scrap steel, 33% return charge, 0.25% molybdenum ferroalloy, 1.4% silicon carbide, 1.7% recarburizer, 0.24% copper, 0.10% ferromanganese, 0.17% ferrochromium, and 0.15% iron sulphur.

[0042] A preparation method of a material for a commercial vehicle brake disc resistant to high thermal fatigue, comprising the following steps:

[0043] Step 1, ingredients;

[0044] Weigh the following raw material ratios by weight: 61% scrap steel, 33% return charge, 0.25% ferromolybdenum alloy, 1.4% silicon carbide, 1.7% recarburizer, 0.24% copper, 0.10% ferromanganese, 0.17% ferrochromium, ferrous sulfide 0.15% of raw materials.

[0045] Step 2, feeding and melting;

[0046] The specific method of feeding and melting is as follows:

[0047] 21) Add 20% scrap steel to the intermediate frequency furnace for smelting;

[0048] 22) Add 1.7% of recarburizer, 1.4% of silicon carbide, 0.10% of ferromanganese and 0.17% of ferrochrome to the intermediate frequency furnace for sme...

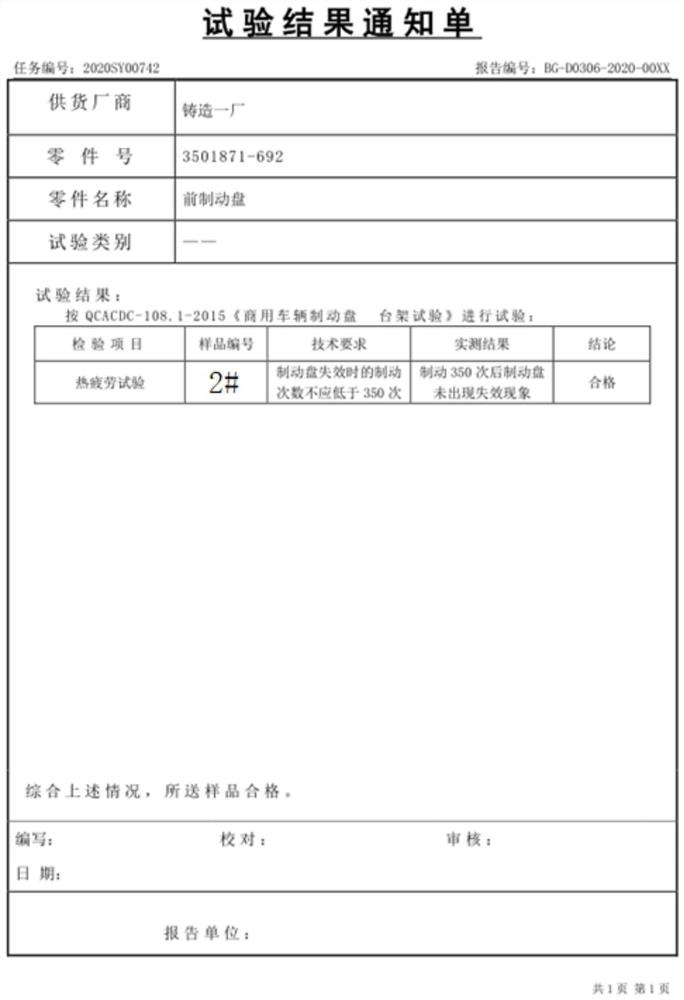

Embodiment 2

[0067] Take 78% scrap steel, 17% return charge, 0.7% molybdenum ferroalloy, 2.0% silicon carbide, 2.5% recarburizer, 0.5% copper, 0.25% ferromanganese, 0.45% ferrochromium, and 0.20% iron sulphur.

[0068] A preparation method of a material for a commercial vehicle brake disc resistant to high thermal fatigue, comprising the following steps:

[0069] Step 1, ingredients;

[0070] Weigh the following raw material proportions according to weight: 78% scrap steel, 17% return charge, 0.7% ferromolybdenum alloy, 2.0% silicon carbide, 2.5% recarburizer, 0.5% copper, 0.25% ferromanganese, 0.45% ferrochromium, ferrosulfide 0.20%.

[0071] Step 2, feeding and melting;

[0072] The specific method of feeding and melting is as follows:

[0073] 21) Add 20% scrap steel to the intermediate frequency furnace for smelting;

[0074] 22) Add 2.5% recarburizer, 2.0% silicon carbide, 0.25% ferromanganese and 0.45% ferrochromium to the intermediate frequency furnace for smelting;

[0075] 23...

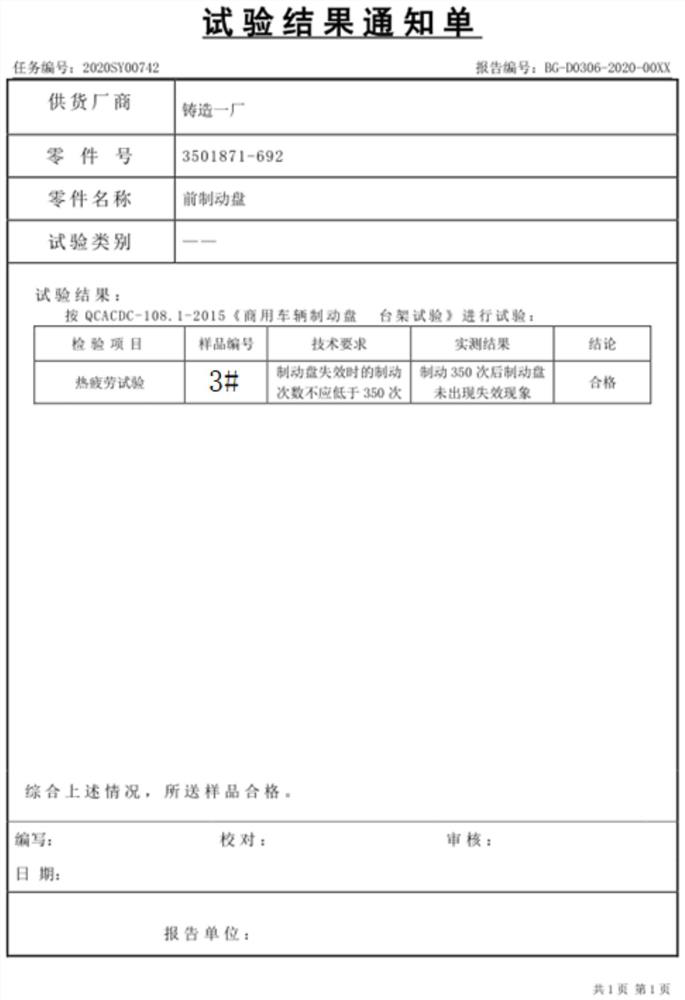

Embodiment 3

[0093] Take 70% scrap steel, 25% return charge, 0.6% ferromolybdenum alloy, 1.7% silicon carbide, 2.2% recarburizer, 0.4% copper, 0.15% ferromanganese, 0.3% ferrochromium, and 0.18% ferrosulfide.

[0094] A preparation method of a material for a commercial vehicle brake disc resistant to high thermal fatigue, comprising the following steps:

[0095] Step 1, ingredients;

[0096] Weigh the following raw material ratios by weight: 70% scrap steel, 25% return charge, 0.6% ferromolybdenum alloy, 1.7% silicon carbide, 2.2% recarburizer, 0.4% copper, 0.15% ferromanganese, 0.3% ferrochromium, ferrosulfide 0.18%.

[0097] Step 2, feeding and melting;

[0098] The specific method of feeding and melting is as follows:

[0099] 21) Add 20% scrap steel to the intermediate frequency furnace for smelting;

[0100] 22) Add 2.2% of recarburizer, 1.7% of silicon carbide, 0.15% of ferromanganese and 0.3% of ferrochromium into the intermediate frequency furnace for smelting;

[0101] 23) Ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com