A kind of solid-liquid dual-phase copper alloy smelting covering agent and its application

A technology of copper alloy and covering agent, which is applied in the field of melt purification in the copper smelting process, can solve the problems of anti-oxidation and volatilization efficiency of the covering agent to be improved, and achieve the effects of reducing the amount of furnace ash, simple preparation steps, and preventing sinking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

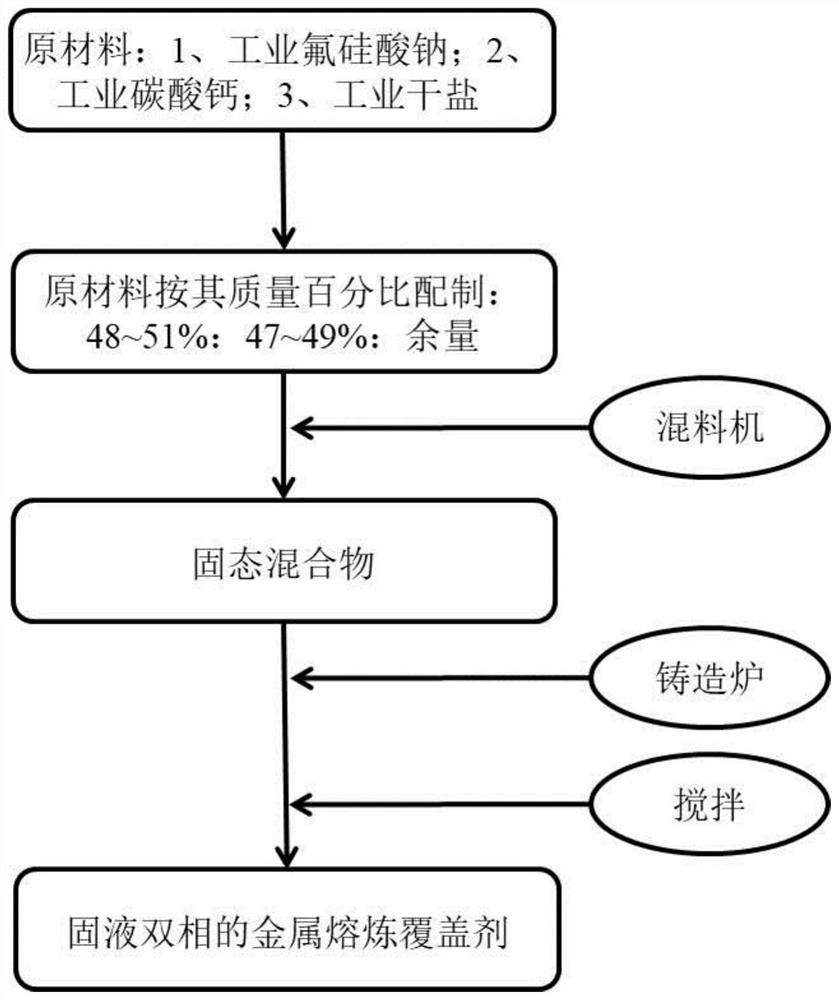

[0049] The application of the solid-liquid two-phase copper alloy smelting covering agent comprises the following application steps:

[0050] (1) Raw materials are prepared in proportion, Na 2 SiF 6 (purity≥98.5%): CaCO 3 (Particle size 100-500 mesh, whiteness ≥ 96%): NaCl (purity ≥ 92%) = 49.5%: 47.5%: 3%;

[0051] (2) Use a mixer to fully mix each raw material component to form a mixture;

[0052] (3) The mixture accounting for 0.25% of the total weight of the copper alloy melt is quantitatively sprinkled on the surface of the copper alloy melt in the casting furnace, and stirred, and the furnace temperature is maintained at 1000° C. to form a covering agent that continuously maintains the solid-liquid dual phase, and the copper The alloy melt was covered for 24 hours, the surface oxide ash in the furnace was collected, the sample was ball milled, washed and dried, and the proportion of the furnace ash and sand head was measured.

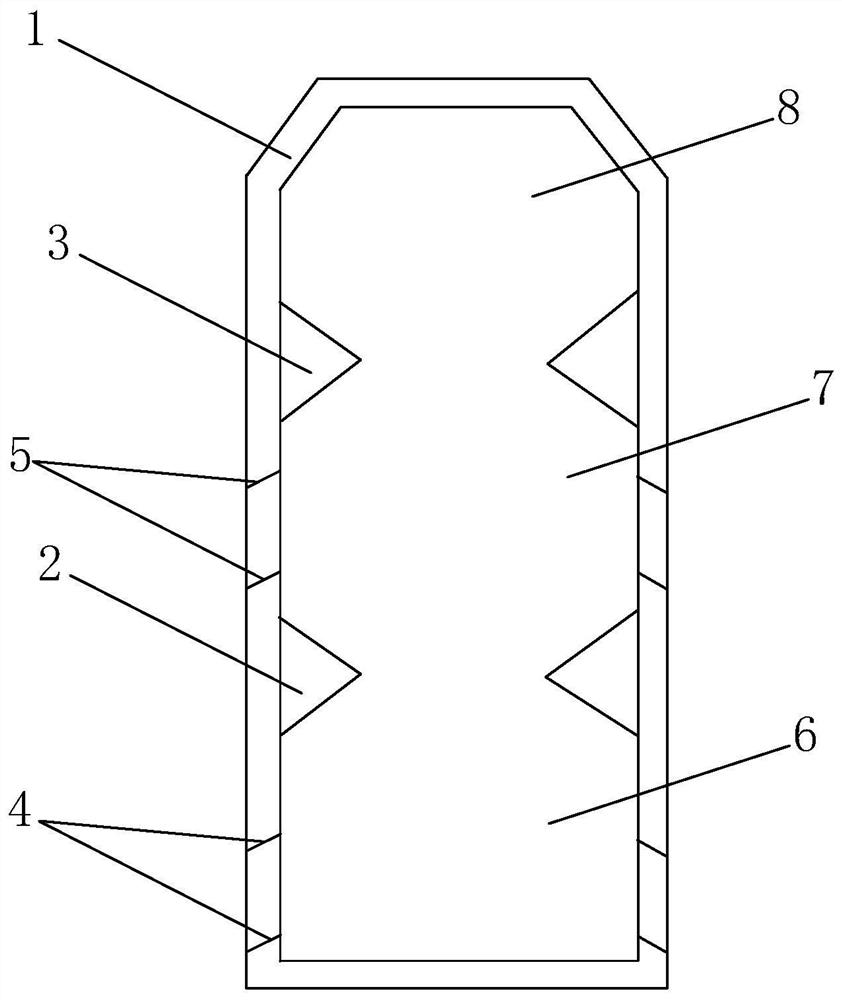

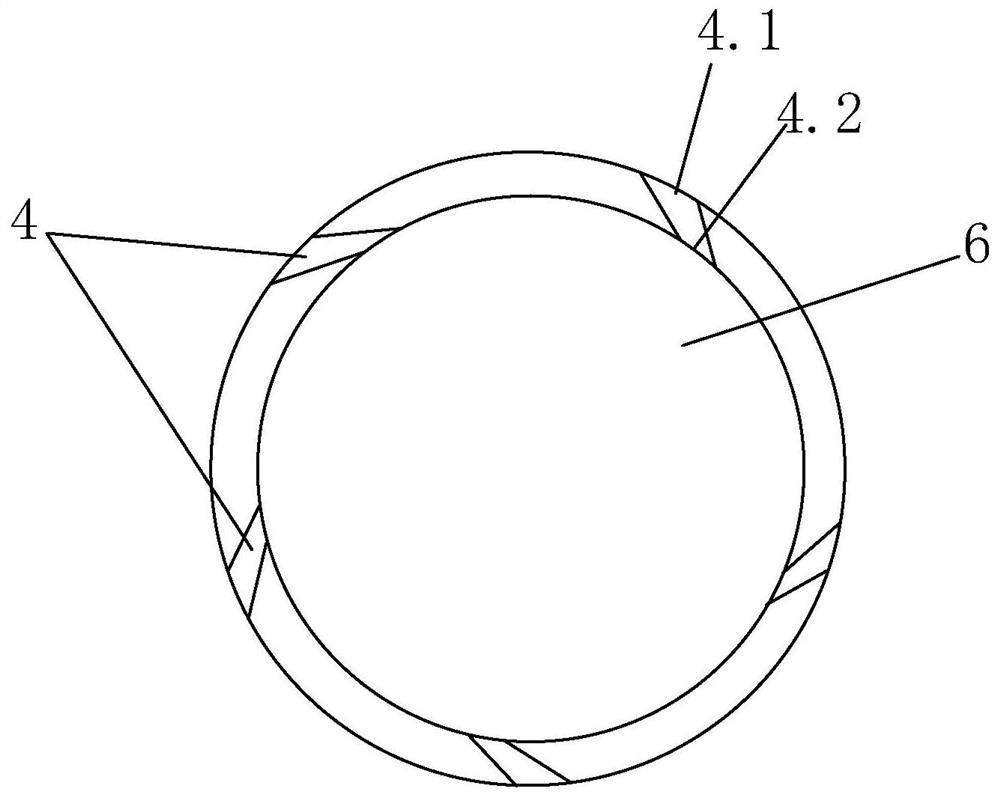

[0053] The casting furnace includes a f...

Embodiment 2

[0055] The application of the solid-liquid two-phase copper alloy smelting covering agent comprises the following application steps:

[0056] (1) Raw materials are prepared in proportion, Na 2 SiF 6 (purity≥98.5%): CaCO 3 (Particle size 100-500 mesh, whiteness ≥ 96%): NaCl (purity ≥ 92%) = 48%: 47%: 5%;

[0057] (2) Use a mixer to fully mix each raw material component to form a mixture;

[0058] (3) Quantitatively sprinkle the mixture accounting for 0.15% to 0.35% of the total weight of the copper alloy melt on the surface of the copper alloy melt in the casting furnace, and stir it to maintain the furnace temperature at 950°C to form a covering agent that continuously maintains the solid-liquid dual phase , Cover the copper alloy melt for 22 hours, collect the surface oxide ash in the furnace, take samples for ball milling, washing and drying, and measure the proportion of the furnace ash sand head.

[0059] The casting furnace includes a furnace body 1, and the furnace b...

Embodiment 3

[0061] The application of the solid-liquid two-phase copper alloy smelting covering agent comprises the following application steps:

[0062] (1) Raw materials are prepared in proportion, Na 2 SiF 6 (purity≥98.5%): CaCO 3 (Particle size 100-500 mesh, whiteness ≥ 96%): NaCl (purity ≥ 92%) = 51%: 48%: 1%;

[0063] (2) Use a mixer to fully mix each raw material component to form a mixture;

[0064] (3) Quantitatively sprinkle the mixture accounting for 0.15% to 0.35% of the total weight of the copper alloy melt on the surface of the copper alloy melt in the casting furnace, and stir it to maintain the furnace temperature at 1100°C to form a covering agent that continuously maintains the solid-liquid dual phase , Cover the copper alloy melt for 20 hours, collect the surface oxidation ash in the furnace, take samples for ball milling, washing and drying, and measure the proportion of the furnace ash sand head.

[0065] The casting furnace includes a furnace body 1, and the furn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com