Grease lubrication two-way thrust conical sliding bearing

A two-way thrust, sliding bearing technology, used in sliding contact bearings, rotating bearings, bearings, etc., can solve the problem of difficult application of super-lubricating materials, improve performance and service life, simple processing, and ensure normal operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

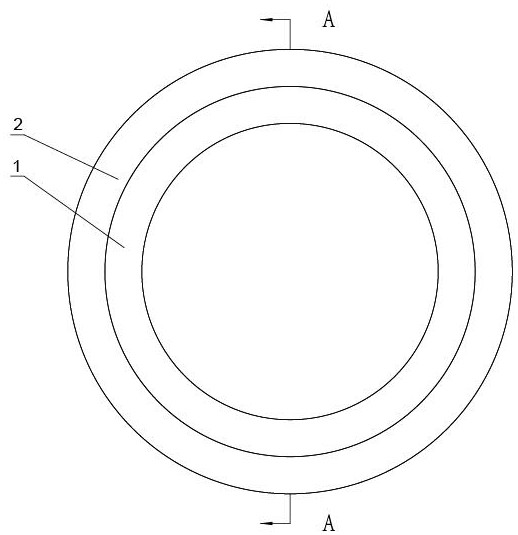

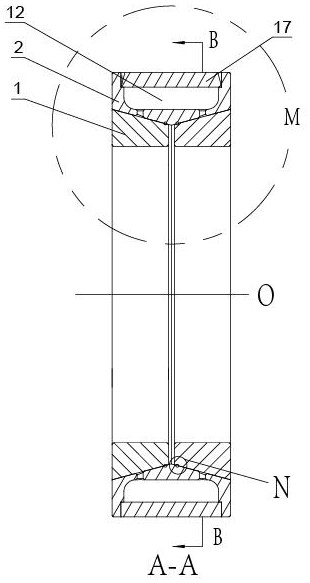

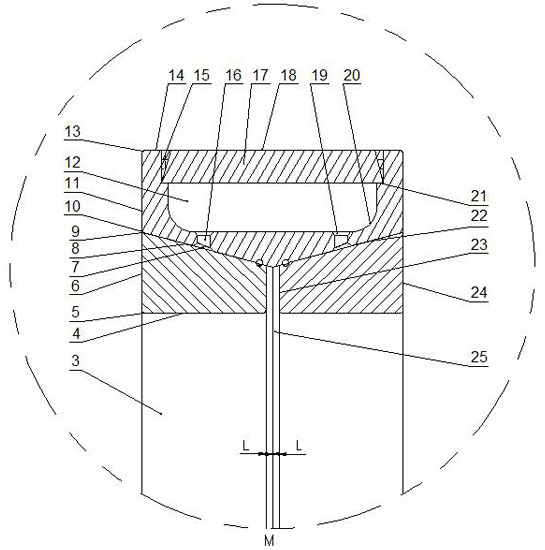

[0045] Example 1: See Figure 1 to 10, The present embodiment is a bi-directional thrust tapered lubricated with grease greasing the outer sliding bearing, comprising a bearing outer ring 2, the bearing outer ring 2 is equipped with two bearings fitted inside the inner ring 1, two bearing outer ring and the inner ring of the bearing frictional contact between the two different inclined directions friction cone surface 8, comprising a friction cone surface cooperating tapered surfaces of the inner and outer tapered surface, two inner bearing ring disposed opposite a small end, and leaving a gap 25 to compensate . Specifically, at the center of the inner bearing ring defines an inner bore of the bearing 3, the bearing bore hole wall 3 of the inner wall of the inner ring 4, an inner bearing ring of the outer wall of the inner cone, the small-diameter inner bearing ring 1 the inner end of the small end 23 to the end face, the end face of the large diameter end of an inner bearing ring ...

Embodiment 2

[0056] Example 2: Please refer to Figures 11-4 , The present embodiment is a bi-directional thrust lubricated with grease Cone greasing sliding bearing, comprising a bearing inner race with a set of two bearings and the outer ring 2, the outer circumferential surface of the bearing inner ring 1 is provided with two large diameter end Cohesion tapered inner friction, the inner circumferential surface of the bearing outer race ring 2 is provided with a friction fit with the tapered inner friction cone surface, two bearing outer ring 2 in a manner opposite to the small diameter end disposed side by side the two inner friction cone surface bearing inner ring 1 is formed tapered surface of the inner ring and the outer friction cone surface friction sliding friction fit friction cone surface 8.

[0057] The two end faces of the small diameter end of the bearing outer ring 2 small end 31 of the outer ring, the large diameter end of the large end face 30 of the outer ring; two end faces o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com