Composite structure printed circuit board type LNG vaporizer core with thermoelectric generator

A thermoelectric generator and printed circuit board technology, which is applied in the directions of generators/motors, electrical components, container discharge methods, etc., can solve the problems such as the utilization method of LNG cold energy that has not yet been seen, and the PCHE channel structure needs to be improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

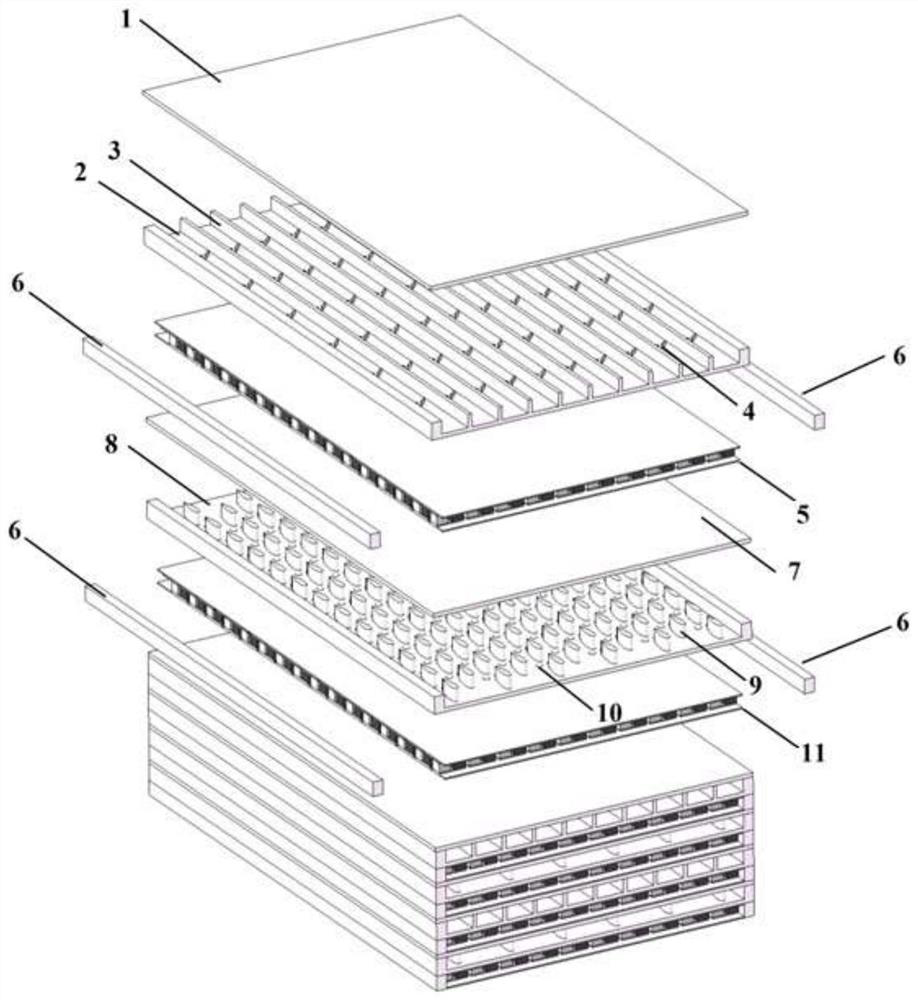

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

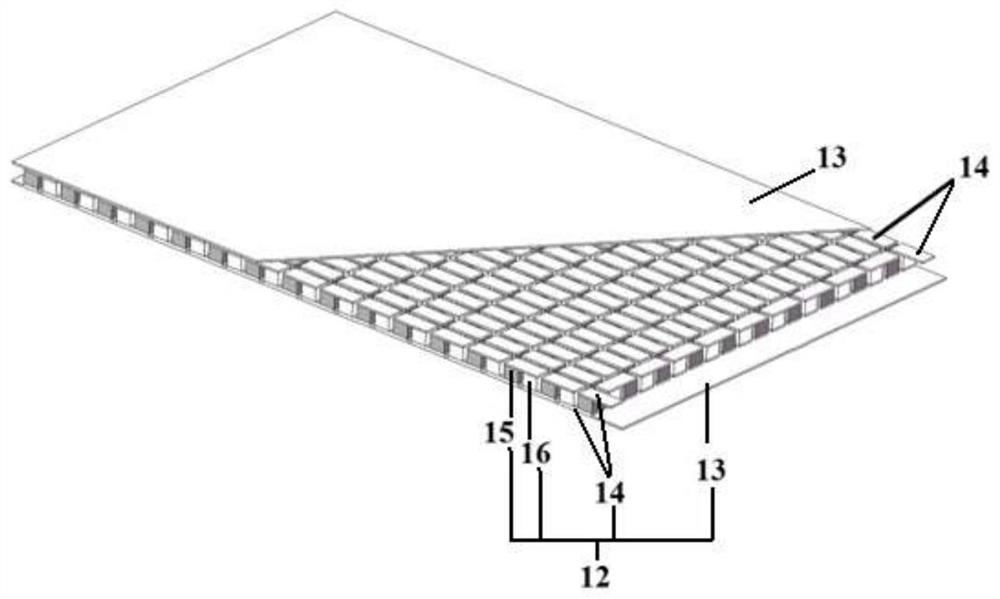

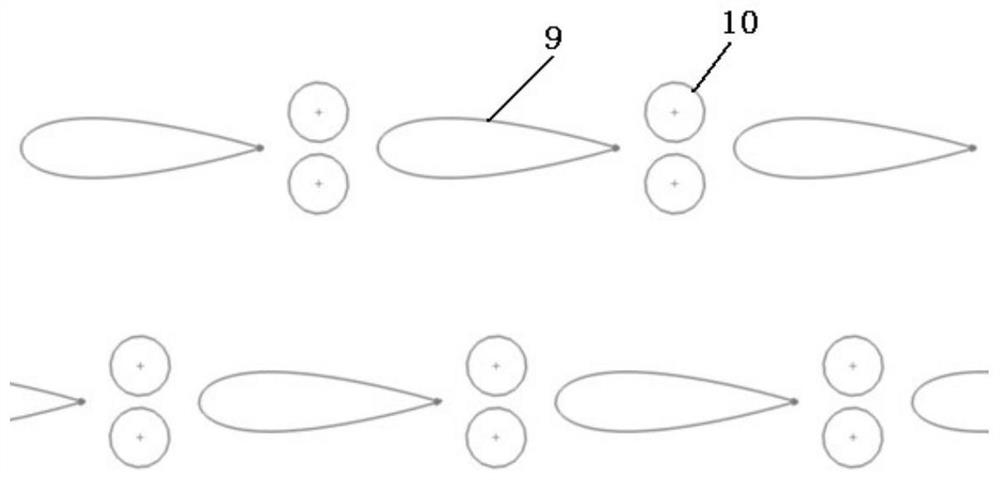

[0025] see figure 1 , figure 2 , a composite structure printed circuit board type LNG vaporizer core body with a thermoelectric generator, comprising straight rib channels and airfoil rib channels arranged alternately stacked up and down; the straight rib channels sequentially include first The separator 1, the straight rib 2 and the first thermoelectric power generation module 5; the airfoil rib channel includes the second separator 7, the airfoil rib 8 and the second thermoelectric power generation module 11 from top to bottom;

[0026] There are guide bars on both sides of the top of the straight rib plate 2, a number of continuous straight ribs 3 are arranged at equal intervals between the guide bars on both sides, and a number of continuous straight ribs 3 are arranged at equal distances between adjacent two continuous straight ribs 3. Tapered longitu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com