High-temperature-resistant bolt-type aluminum electrolytic capacitor

An aluminum electrolytic capacitor and bolt-type technology, which is applied in the field of capacitors, can solve the problems of poor heat dissipation effect of capacitors, easy entry of dust or sundries, etc., and achieve the effect of solving poor heat dissipation effect, improving heat dissipation effect, and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031]By setting the filter assembly 7 and the heat conduction module 5, the technical problem of poor heat dissipation effect of the capacitor and easy entry of dust or sundries in the prior art is effectively solved, thereby realizing the improvement of the heat dissipation effect of the capacitor and avoiding the entry of dust or sundries technical effect.

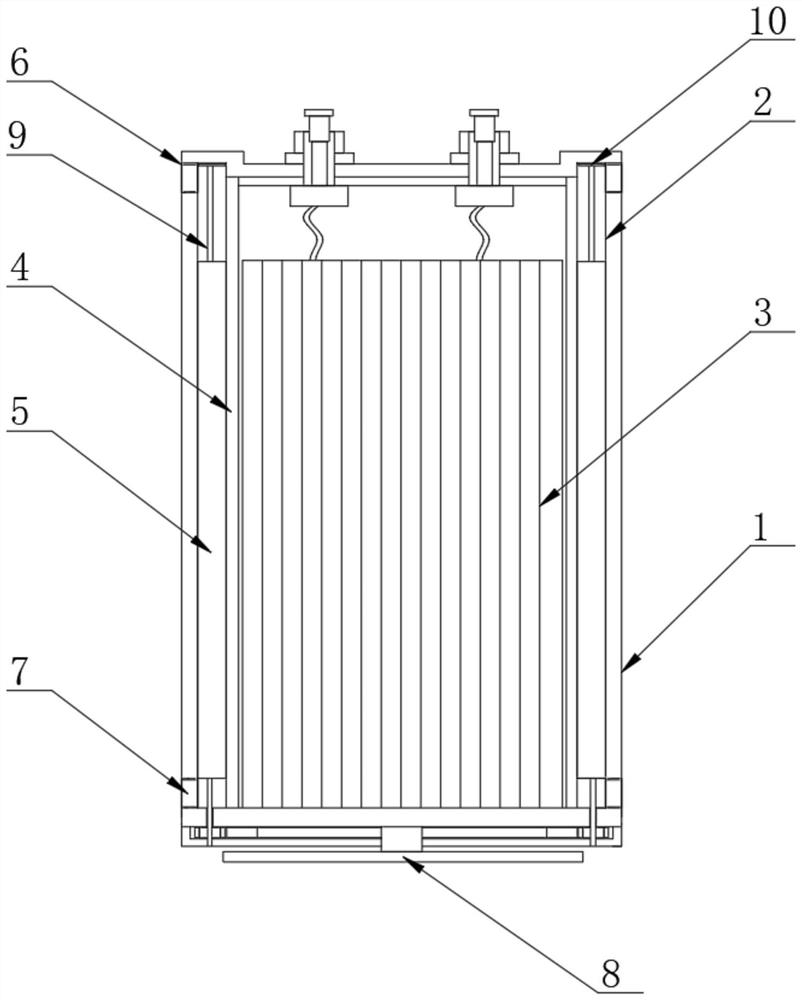

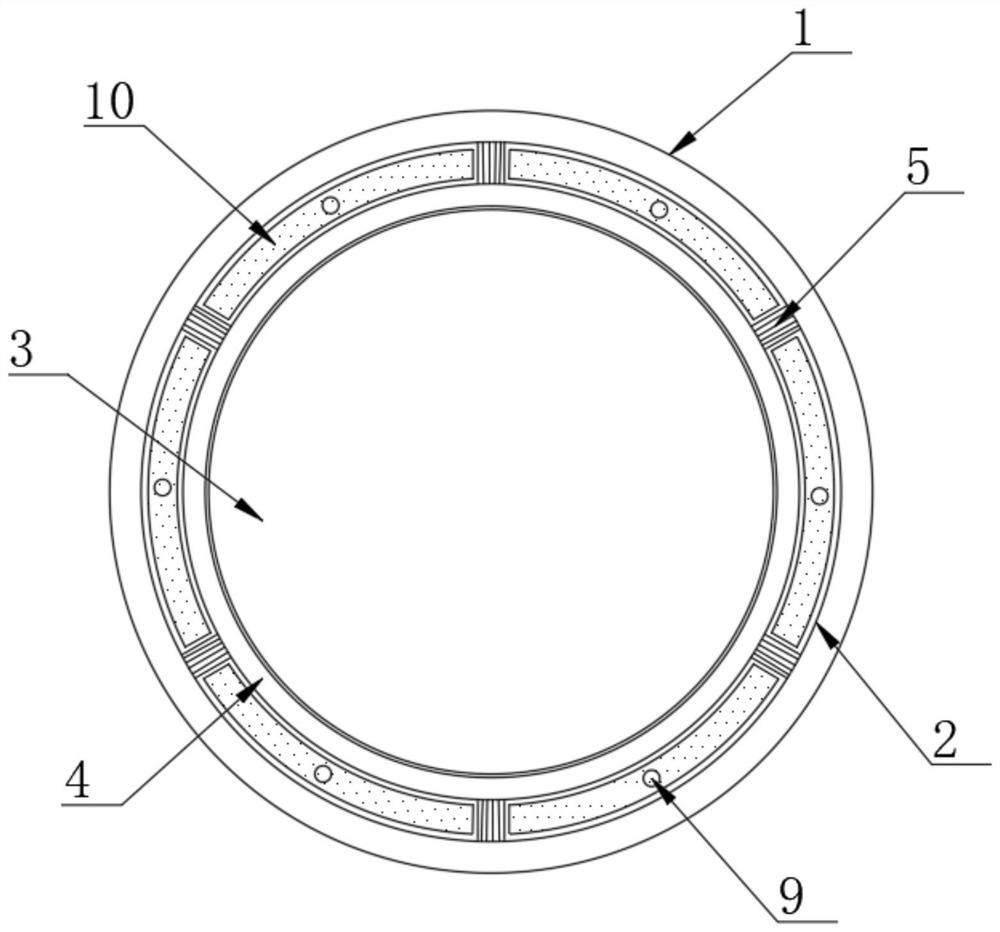

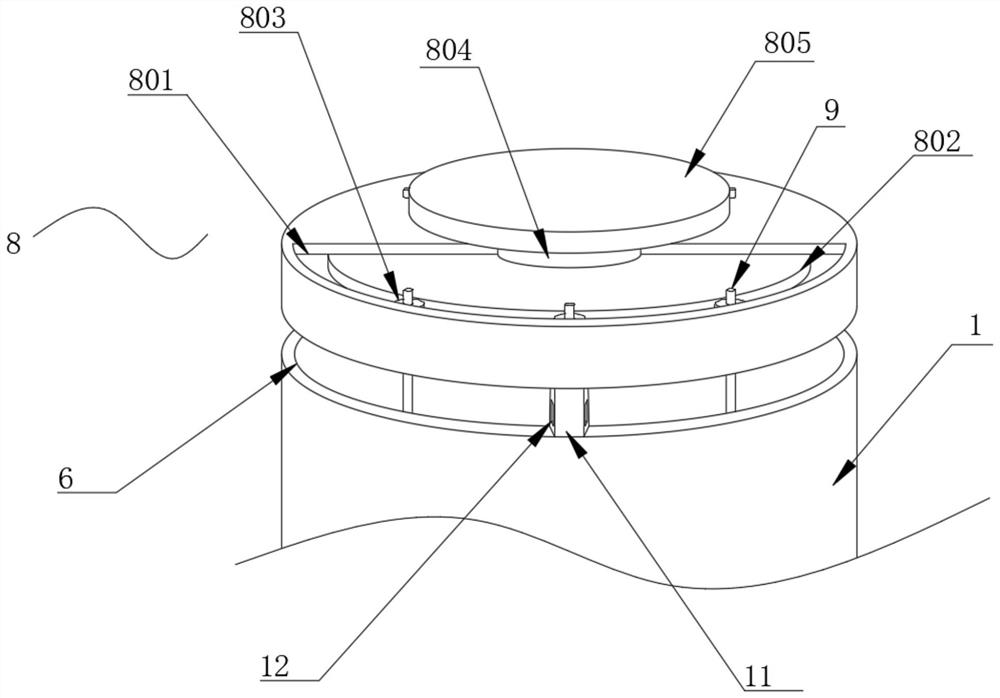

[0032] In order to better understand the above-mentioned technical solution, the above-mentioned technical solution will be described in detail below in conjunction with the accompanying drawings and specific implementation methods.

[0033] see Figure 1-8 , in the embodiment of the present application, a high temperature resistant bolt type aluminum electrolytic capacitor includes a case 1, a chamber 2 is opened inside the case 1, and a core 3 is fixed inside the chamber 2; the top of the outer surface of the case 1 and the The bottom ends are provided with at least two air inlets 6, and the interior of the air inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com