Biological material screening equipment capable of ensuring same particle size

A technology of material screening and sorting equipment, which is used in sieving, solid separation, grain processing, etc., can solve the problems of difficulty in ensuring the same particle size, reducing the quality of raw materials, and low screening efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

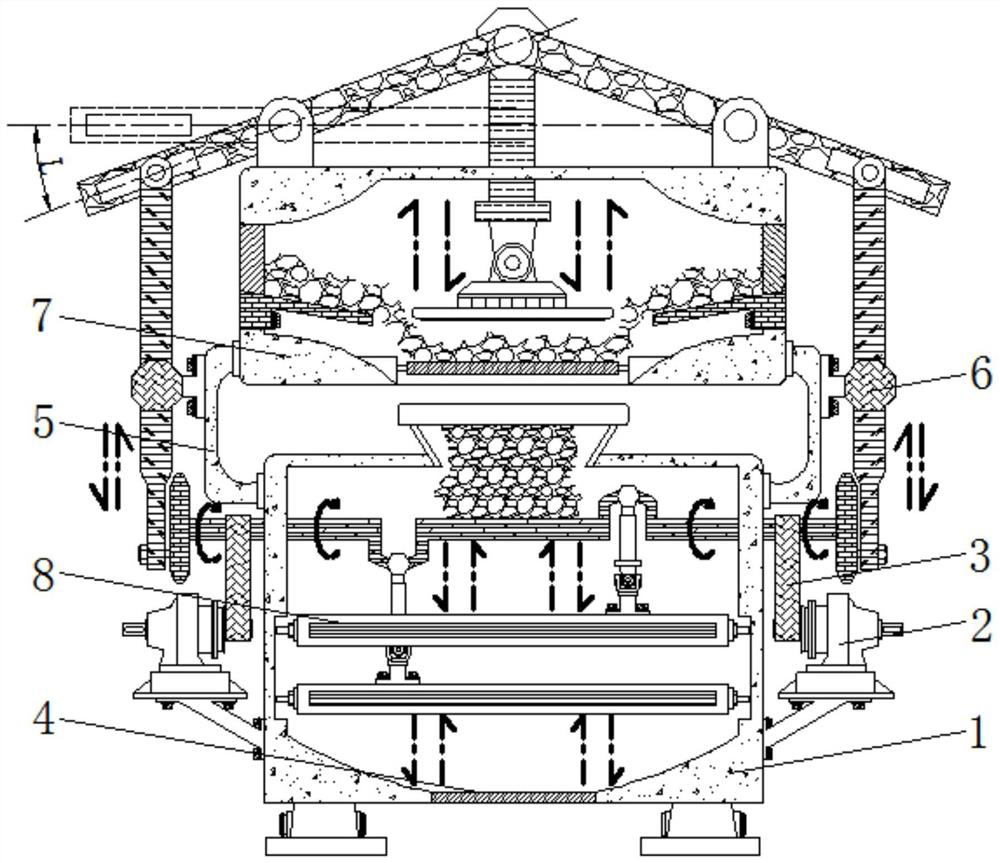

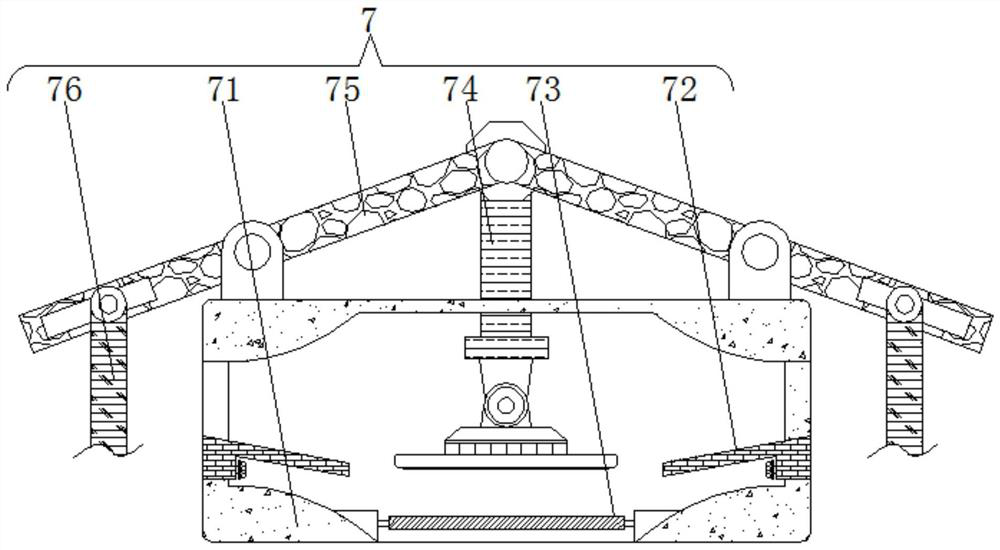

[0023] see figure 1 , figure 2 The outer side of the screening box 1 is welded with a driving machine 2, the periphery of the driving machine 2 is sleeved with a belt 3, the bottom of the screening box 1 is provided with a discharge port 4, and the side of the top of the screening box 1 is welded with a fixed plate 5, The side of the fixed plate 5 is welded with a sliding sleeve 6, the driving machine 2 is provided with two, respectively welded on the left and right sides of the outside of the screening box 1, and the belt 3 is provided with two, respectively sleeved on the left and right sides of the two driving machines 2. Periphery, the discharge port 4 is set in the middle of the bottom of the screening box 1, and there are two fixing plates 5, which are respectively welded to the left and right ends of the top of the screening box 1, and between the feeding box 71 and the screening box 1 Through the welding of the two fixing plates 5, there are two sliding sleeves 6, wh...

Embodiment 2

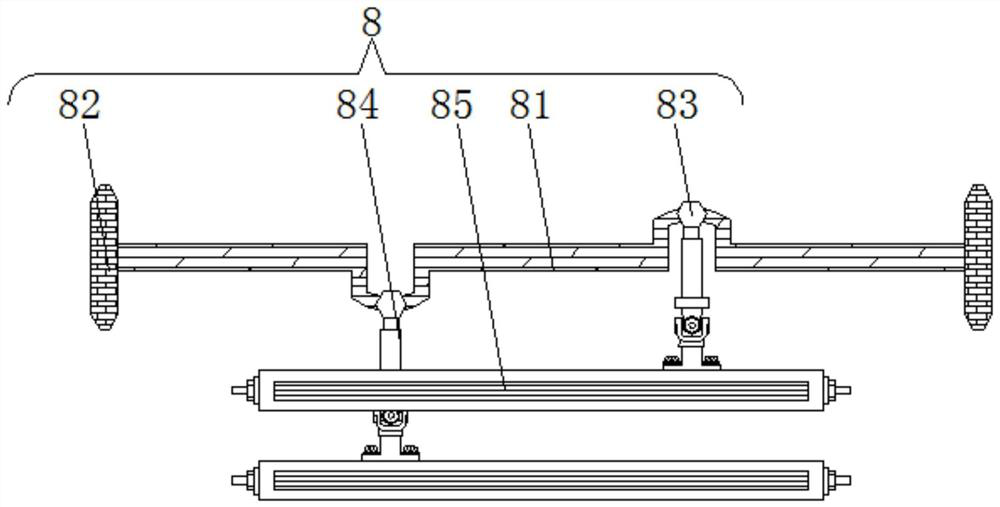

[0027] see figure 1 , image 3 The outer side of the screening box 1 is welded with a driving machine 2, the periphery of the driving machine 2 is sleeved with a belt 3, the bottom of the screening box 1 is provided with a discharge port 4, and the side of the top of the screening box 1 is welded with a fixed plate 5, The side of the fixed plate 5 is welded with a sliding sleeve 6, the driving machine 2 is provided with two, respectively welded on the left and right sides of the outside of the screening box 1, and the belt 3 is provided with two, respectively sleeved on the left and right sides of the two driving machines 2. Periphery, the discharge port 4 is set in the middle of the bottom of the screening box 1, and there are two fixing plates 5, which are respectively welded to the left and right ends of the top of the screening box 1, and between the feeding box 71 and the screening box 1 Through the welding of the two fixing plates 5, there are two sliding sleeves 6, whi...

Embodiment 3

[0031] see Figure 1-3 The outer side of the screening box 1 is welded with a driving machine 2, the periphery of the driving machine 2 is sleeved with a belt 3, the bottom of the screening box 1 is provided with a discharge port 4, and the side of the top of the screening box 1 is welded with a fixed plate 5, The side of the fixed plate 5 is welded with a sliding sleeve 6, the driving machine 2 is provided with two, respectively welded on the left and right sides of the outside of the screening box 1, and the belt 3 is provided with two, respectively sleeved on the left and right sides of the two driving machines 2. Periphery, the discharge port 4 is set in the middle of the bottom of the screening box 1, and there are two fixing plates 5, which are respectively welded to the left and right ends of the top of the screening box 1, and between the feeding box 71 and the screening box 1 Through the welding of the two fixing plates 5, there are two sliding sleeves 6, which are re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com