Fe (III) cluster/bismuth oxyiodate composite photocatalytic material and preparation method and application thereof

A technology of composite photocatalysis and bismuth oxyiodate, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the low recombination efficiency of photogenerated electrons and holes , affecting the stability of the composite photocatalyst, high photogenerated electron-hole recombination rate, etc., to achieve the effect of improving photocatalytic performance, excellent photocatalytic performance, and broadening the range of light absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] An Fe(III) cluster / bismuth oxyiodate composite photocatalytic material comprises Fe(III) clusters and defect-type bismuth oxyiodate, and the Fe(III) cluster is supported on the defect-type bismuth oxyiodate.

[0036] In this embodiment, the mass ratio of the Fe(III) clusters to the defective bismuth oxyiodate in the Fe(III) cluster / bismuth oxyiodate composite photocatalytic material is 1:2000.

[0037] A kind of preparation method of the Fe(Ⅲ) cluster / bismuth oxyiodate composite photocatalytic material of above-mentioned present embodiment, comprises the following steps:

[0038] S1. Accurately weigh 1 mmol of bismuth nitrate pentahydrate and 1 mmol of sodium iodate into 80 mL of water, stir magnetically for 2 hours in the dark at room temperature, wash the white precipitate with water and ethanol alternately for 3 times, and store at 60°C Drying for 12 hours under the hood to obtain bismuth oxyiodate.

[0039] S2. Put the bismuth oxyiodate obtained in S1 into an alumi...

Embodiment 2

[0042] A kind of Fe(Ⅲ) cluster / bismuth oxyiodate composite photocatalytic material is basically the same as Example 1, the difference is only: in the Fe(Ⅲ) cluster / bismuth oxyiodate composite photocatalytic material of embodiment 2, Fe (Ⅲ) The mass ratio of the cluster to the defect-type bismuth oxyiodate is 2:2000.

[0043] A preparation method of the Fe(III) cluster / bismuth oxyiodate composite photocatalytic material in the above-mentioned present embodiment is basically the same as the preparation method in Example 1, the difference is only: in the preparation method in Example 2 The consumption of raw material iron trichloride hexahydrate is 0.0020g.

Embodiment 3

[0045] A kind of Fe(Ⅲ) cluster / bismuth oxyiodate composite photocatalytic material is basically the same as embodiment 1, the difference is only: in the Fe(Ⅲ) cluster / bismuth oxyiodate composite photocatalytic material of embodiment 3, Fe (Ⅲ) The mass ratio of the cluster to the defect-type bismuth oxyiodate is 6:2000.

[0046] A preparation method of the Fe(III) cluster / bismuth oxyiodate composite photocatalytic material in the above-mentioned present embodiment is basically the same as the preparation method in Example 1, the difference is only: in the preparation method in Example 3 The consumption of raw material iron trichloride hexahydrate is 0.0060g.

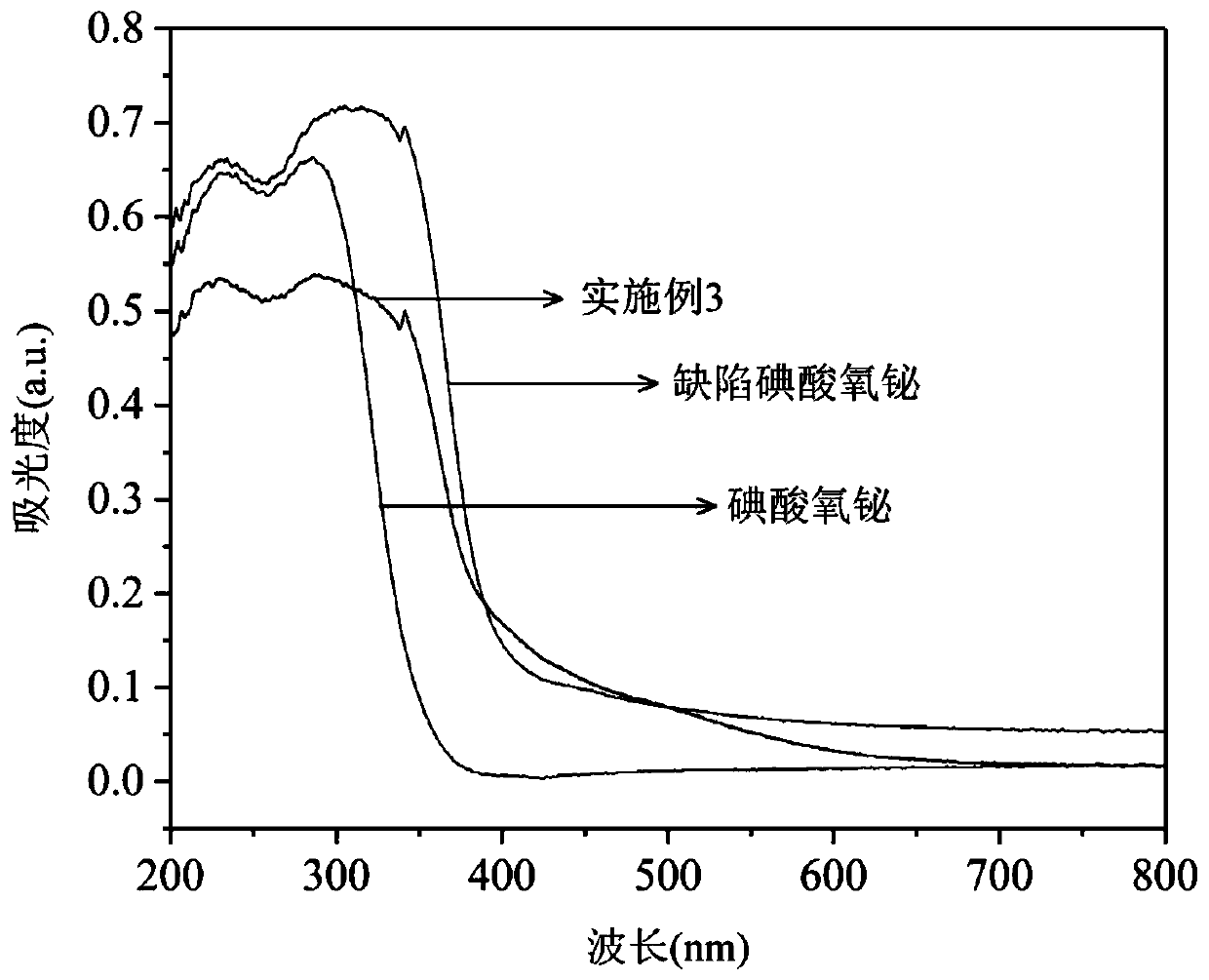

[0047] figure 1 It is a scanning electron microscope image of the Fe(III) cluster / bismuth oxyiodate composite photocatalytic material prepared in Example 3 of the present invention. From figure 1 It can be seen that after Fe(Ⅲ) clusters are loaded, the surface of defective bismuth oxyiodate becomes smoother, and these ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com