Bismuth ferrite/bismuth tungstate heterojunction photocatalytic material and preparation method thereof

A technology of photocatalytic materials, bismuth ferrite, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as difficult formation, achieve excellent performance, strong pollutant degradation ability, wide Effect of visible light absorption range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

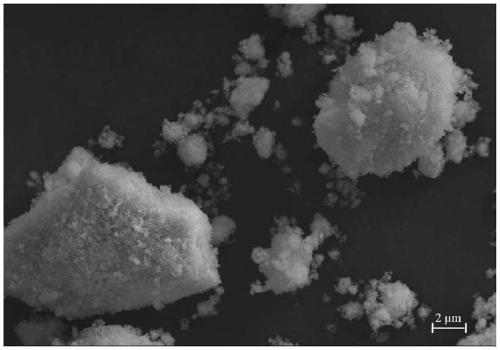

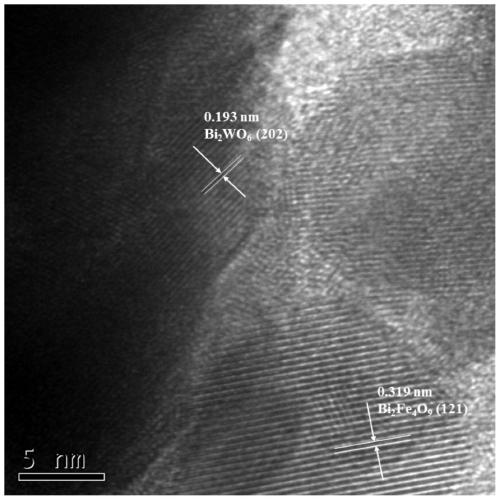

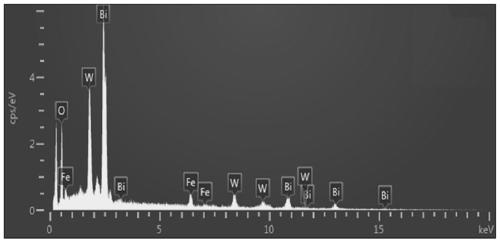

[0038] A bismuth ferrite / bismuth tungstate heterojunction photocatalytic material, including bismuth ferrite and bismuth tungstate, bismuth tungstate is attached to bismuth ferrite to form a heterojunction material, bismuth ferrite is Bi 2 Fe 4 o 9 .

[0039] In this embodiment, the mass ratio of bismuth ferrite to bismuth tungstate in the bismuth ferrite / bismuth tungstate heterojunction photocatalytic material is 1:20.

[0040] A preparation method of the bismuth ferrite / bismuth tungstate heterojunction photocatalytic material of the above-mentioned present embodiment, comprising the following steps:

[0041] (1) 10mmol bismuth nitrate pentahydrate and 10mmol ferric nitrate nonahydrate were dissolved in 15mL nitric acid solution (the nitric acid solution was prepared by mixing 2mL concentrated nitric acid with 13mL deionized water), and magnetically stirred for 30 minutes to obtain bismuth nitrate and nitric acid The mixed solution of iron; in the mixed solution of bismuth...

Embodiment 2

[0044] A bismuth ferrite / bismuth tungstate heterojunction photocatalytic material, which is basically the same as the bismuth ferrite / bismuth tungstate heterojunction photocatalytic material in Example 1, the only difference being: the bismuth ferrite / tungsten in Example 2 The mass ratio of bismuth ferrite to bismuth tungstate in the bismuth acid heterojunction photocatalytic material is 7:100.

[0045] A preparation method of the above-mentioned bismuth ferrite / bismuth tungstate heterojunction photocatalytic material in this embodiment is basically the same as the preparation method of the bismuth ferrite / bismuth tungstate heterojunction photocatalytic material in Example 1, the only difference is : the consumption of bismuth ferrite in the step (2) of embodiment 2 preparation method is 0.0489g.

[0046] Preparation bismuth ferrite / bismuth tungstate heterojunction photocatalytic material (Bi 2 Fe 4 o 9 / Bi 2 WO 6 ), numbered A2.

Embodiment 3

[0048] A bismuth ferrite / bismuth tungstate heterojunction photocatalytic material is basically the same as the bismuth ferrite / bismuth tungstate heterojunction photocatalytic material in Example 1, the only difference being: the bismuth ferrite / tungsten in Example 3 The mass ratio of bismuth ferrite to bismuth tungstate in the bismuth acid heterojunction photocatalytic material is 1:10.

[0049] A preparation method of the above-mentioned bismuth ferrite / bismuth tungstate heterojunction photocatalytic material in this embodiment is basically the same as the preparation method of the bismuth ferrite / bismuth tungstate heterojunction photocatalytic material in Example 1, the only difference is : the consumption of bismuth ferrite in the step (2) of embodiment 3 preparation method is 0.0698g.

[0050] Preparation bismuth ferrite / bismuth tungstate heterojunction photocatalytic material (Bi 2 Fe 4 o 9 / Bi 2 WO 6 ), numbered A3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com