Two-way edge rolling machine

A technology of rolling machine and reducer, which is applied in the direction of metal processing equipment, feeding device, positioning device, etc., can solve the problems of high labor intensity, low processing efficiency, high processing cost, etc., and achieve low labor intensity, high processing efficiency, The effect of less manual intervention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

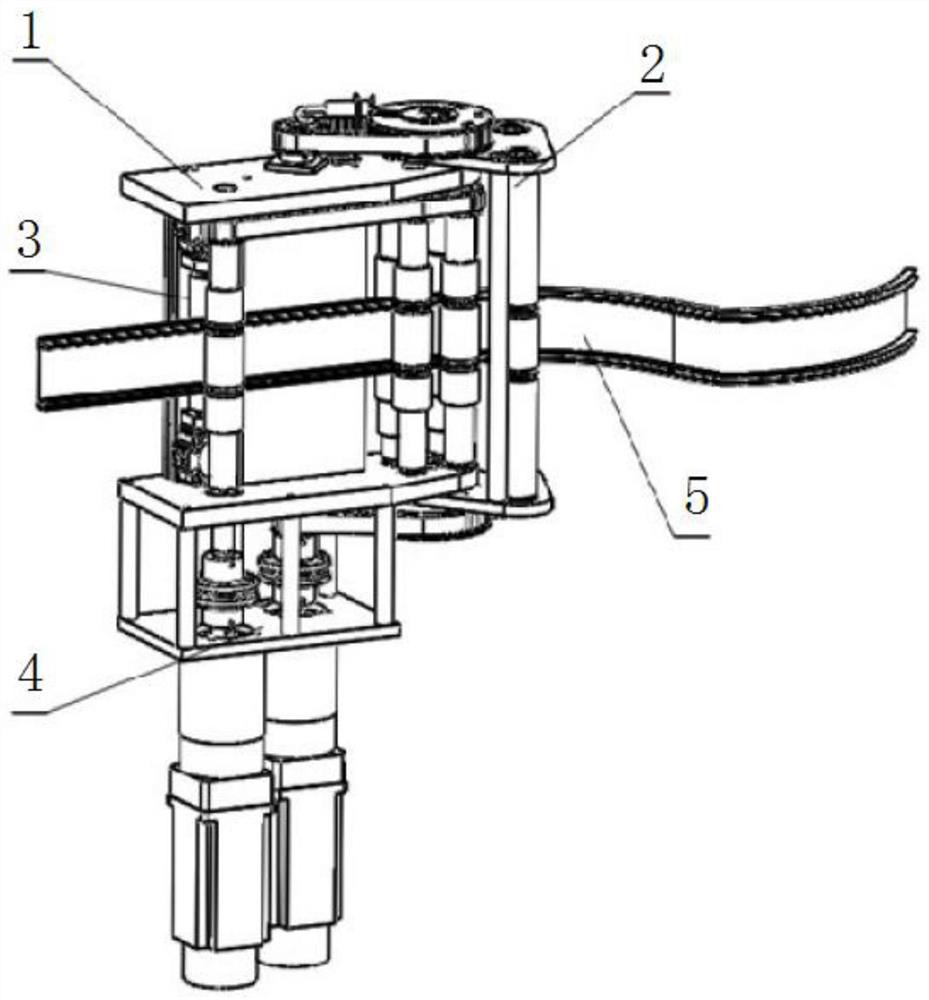

[0028] Embodiment 1: as figure 1 As shown, a two-way round rolling machine is mainly composed of a feeding assembly 1 , a clamping assembly 3 , a bending assembly 2 and a driving assembly 4 .

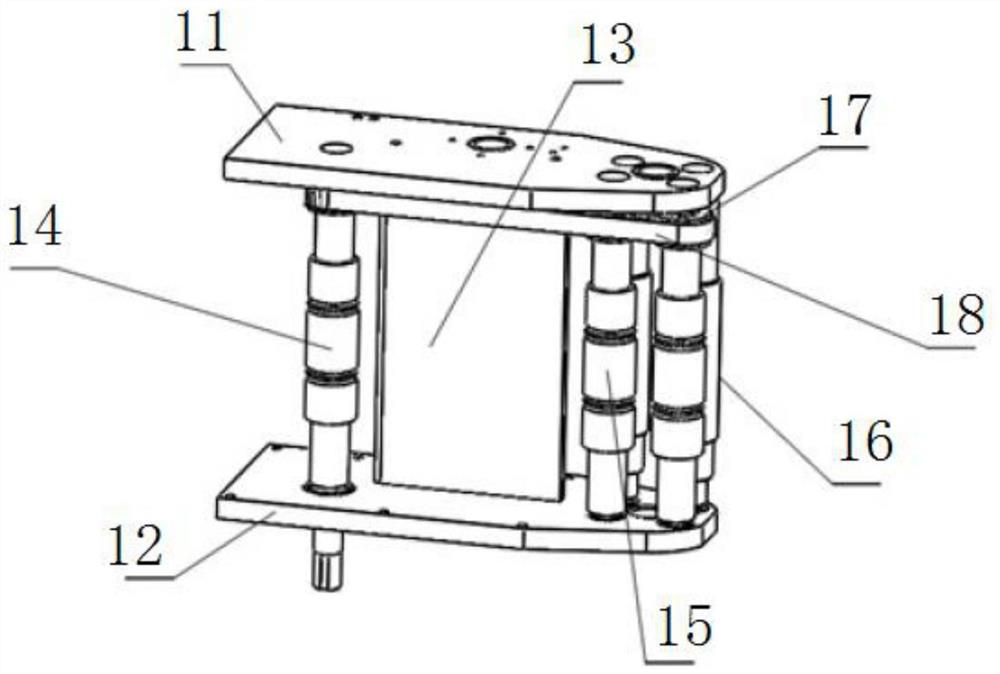

[0029] Among them: such as figure 2 As shown, the feeding assembly 1 includes an upper plate 11, a lower plate 12, a feeding driving roller 14, a feeding driving roller 15 and a feeding passive roller 16; the upper plate 11 and the lower plate 12 are connected and fixed by setting a support plate 13 , the feeding driving roller 15 and the feeding passive roller 16 are each provided with two, the two feeding driving rollers 15 and the two feeding passive rollers 16 are parallel and aligned front and rear, the feeding driving roller 14, two The feeding driving roller 15 and the two feeding passive rollers 16 are installed and fixed by the upper bearing, the lower bearing, the upper plate 11 and the lower plate 12 respectively, and the feeding driving roller 14 is on the same side as the...

Embodiment 2

[0036] Embodiment 2: as Figures 1 to 5 As shown, a two-way rolling machine differs from Embodiment 1 in that the drive assembly 4 also includes a reducer mounting plate 41 connected to the lower plate 12 through a plurality of fixing columns 42, and the reducer is installed Two speed reducers 43 are arranged below the plate 41, and the two speed reducers 43 are connected with the first drive motor 45 and the second drive motor 44 respectively; the output terminals of the first drive motor 45 and the second drive motor 44 They are respectively connected to the feeding driving roller 14 and the bending driving shaft 21 through a coupling 46 .

Embodiment 3

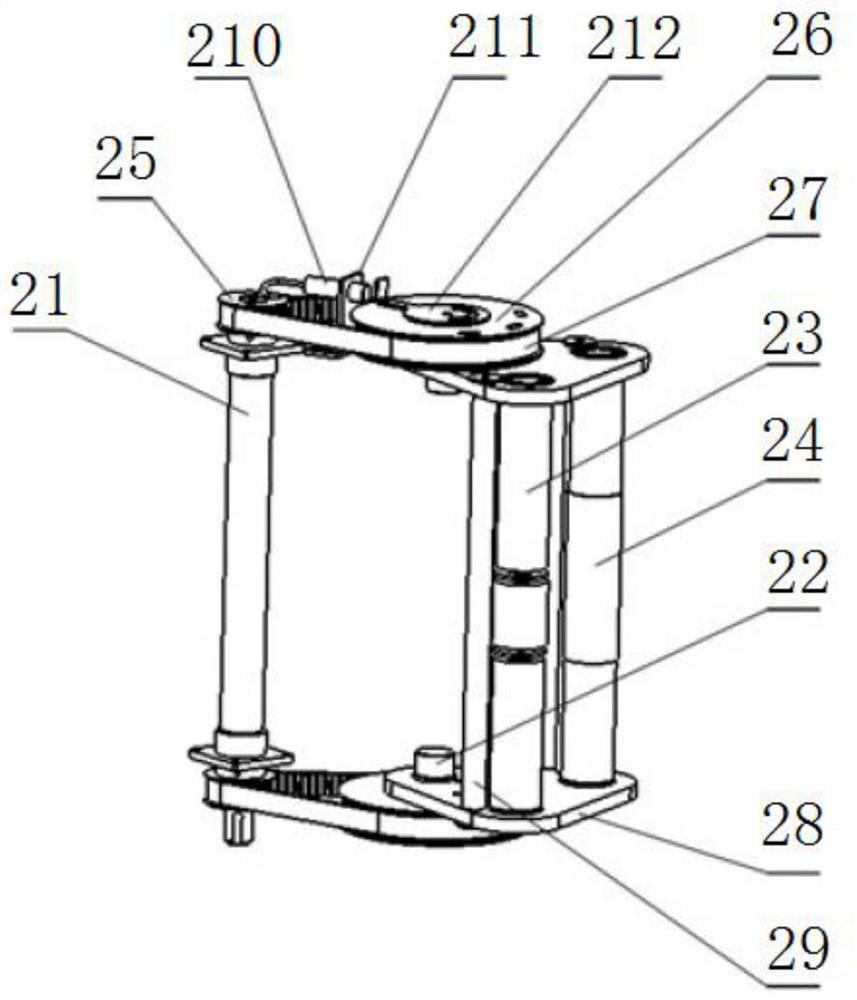

[0037] Embodiment 3: as Figures 1 to 5 As shown, a two-way rolling machine differs from Embodiment 2 in that an origin sensor trigger plate 212 is provided on the driven pulley 26 above, and the origin sensor trigger plate 212 is used to trigger and fix on the sensor bracket 211 The origin sensor 210 on the upper plate, the sensor bracket 211 is arranged on the upper plate 11; the origin sensor 210 is connected to the controller, and the controller is connected to the first driving motor 45 and the second driving motor 44 respectively.

[0038] In the two-way rounding machine described in Embodiment 3, the origin sensor 210 is used to judge the position of the bending assembly 2, and transmit the detected position information to the controller. As well as the roll diameter, control the output angle and direction of the second drive motor, and then control the rotation angle and rotation direction of the bending rollers, so as to realize the elliptical equal diameter arc proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com