Conveying device for industrial electrical automatic production

A technology for electrical automation, conveying devices, used in cleaning devices, transportation and packaging, conveyors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

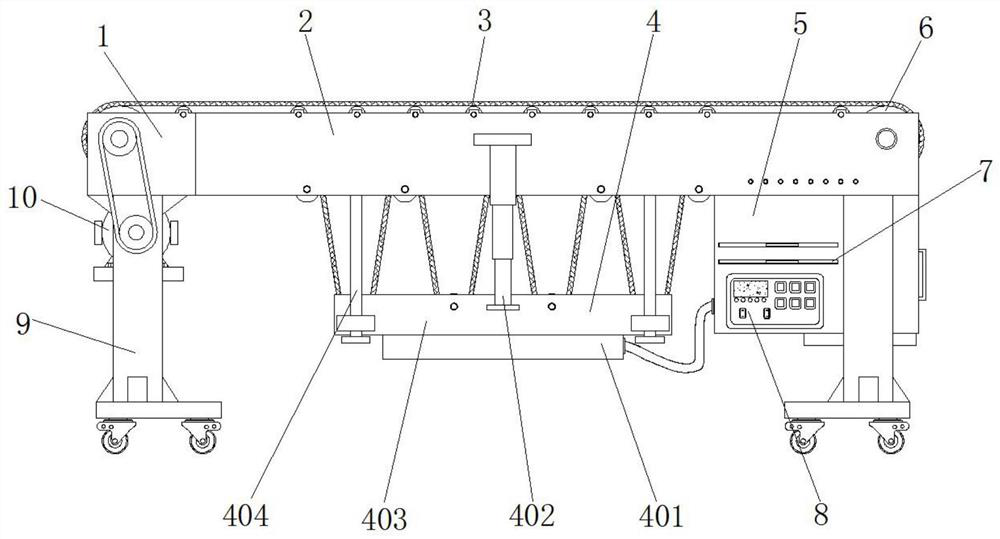

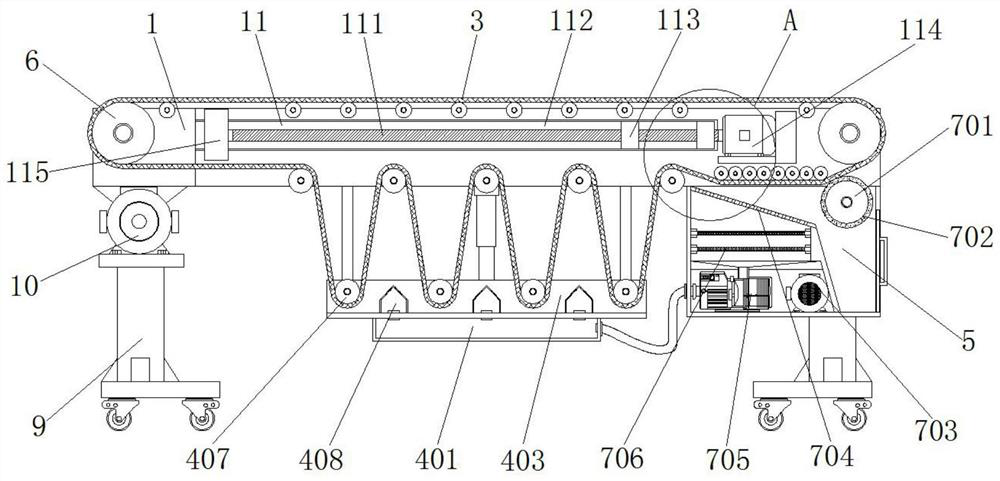

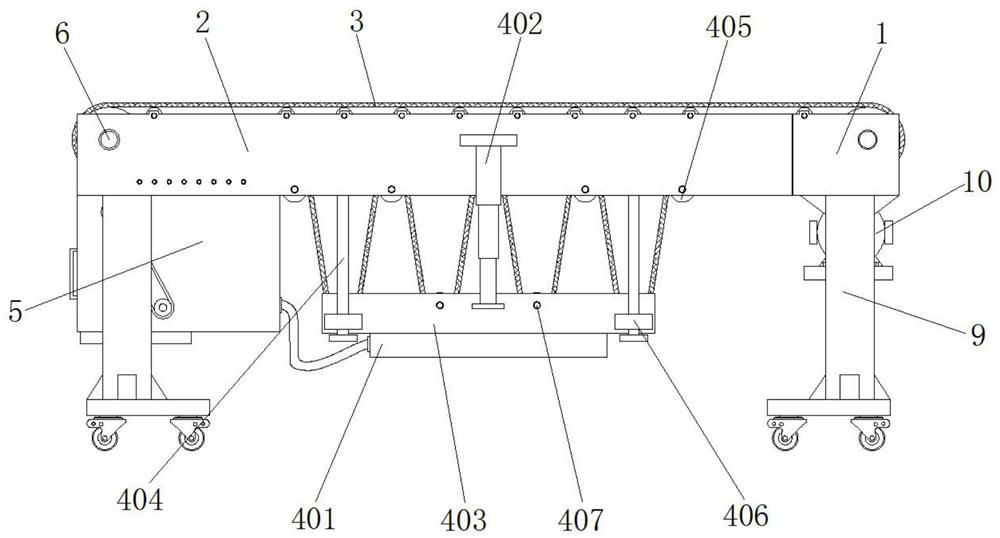

[0040] Example 1, such as Figure 1-7 As shown, when it is necessary to adjust the transmission distance of the installation device, the servo motor 114 can be controlled to drive the threaded rod 111 to rotate, and due to the action of the thread, the moving plate 113 is forced to drive the limit slide bar 112 and the end of the installation seat 1 away from the installation frame 2 move, and the limit slide bar 112 gradually protrudes from the inside of the limit chute 116, and the universal wheel at the bottom of the support column 9 rolls on the ground. In the process, the two groups of electric lifting rods 402 are gradually shortened, so that the first guide The distance between the roller 405 and the second guide roller 407 is gradually shortened, and a length of conveyor belt 3 is released to match the distance between the mounting seat 1 and the mounting frame 2. The driving assembly 10 drives the main guide roller 6 and the conveyor belt 3 to rotate to carry out the ...

Embodiment 2

[0041] Example 2, such as Figure 1-9 As shown, if the device transports industrial dust materials, some of the dust materials will adhere to the outside of the conveyor belt 3. During the process of conveying materials by the device, the control panel 8 controls the second drive assembly 703 to drive the third guide roller. 701 rotates, use the brush 702 on the outside of the third guide roller 701 to clean the outside of the conveyor belt 3, and the material dust that is cleaned is sucked into the inside of the filter chamber 707 by the air pump 705, and filtered by two sets of filter screens 706 It is discharged from the output end of the air pump 705, and the larger dust pieces attached to the outside of the conveyor belt 3 are brushed by the brush 702 and rolled down to the inner bottom of the installation chamber 5, thereby preventing industrial materials from adhering to the outside of the conveyor belt 3 for a long time. 3 cause corrosion, regularly open the door of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com