A rare metal replacement equipment for rare earth industry

A rare metal and equipment replacement technology, which is applied in the direction of improving process efficiency, can solve problems such as low work efficiency, time-consuming and labor-intensive metallurgy, and achieve the effects of saving time, reducing labor intensity, and avoiding splashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

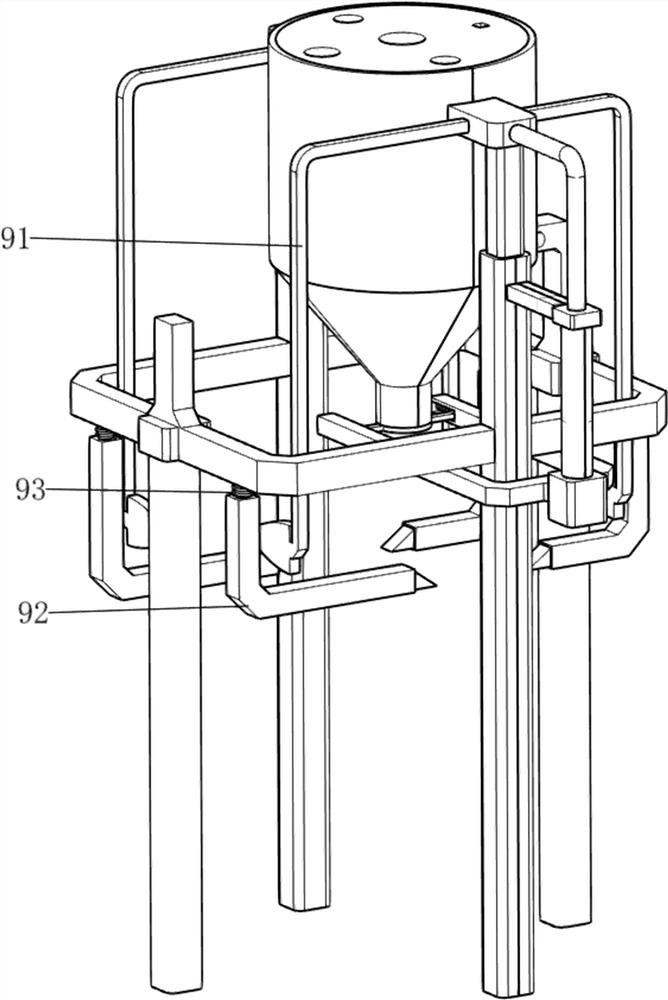

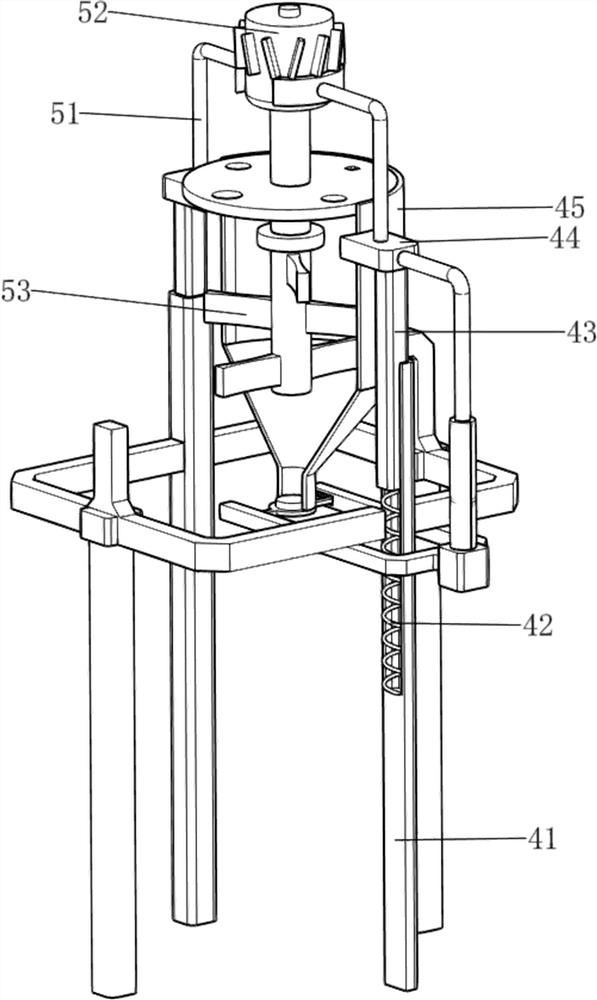

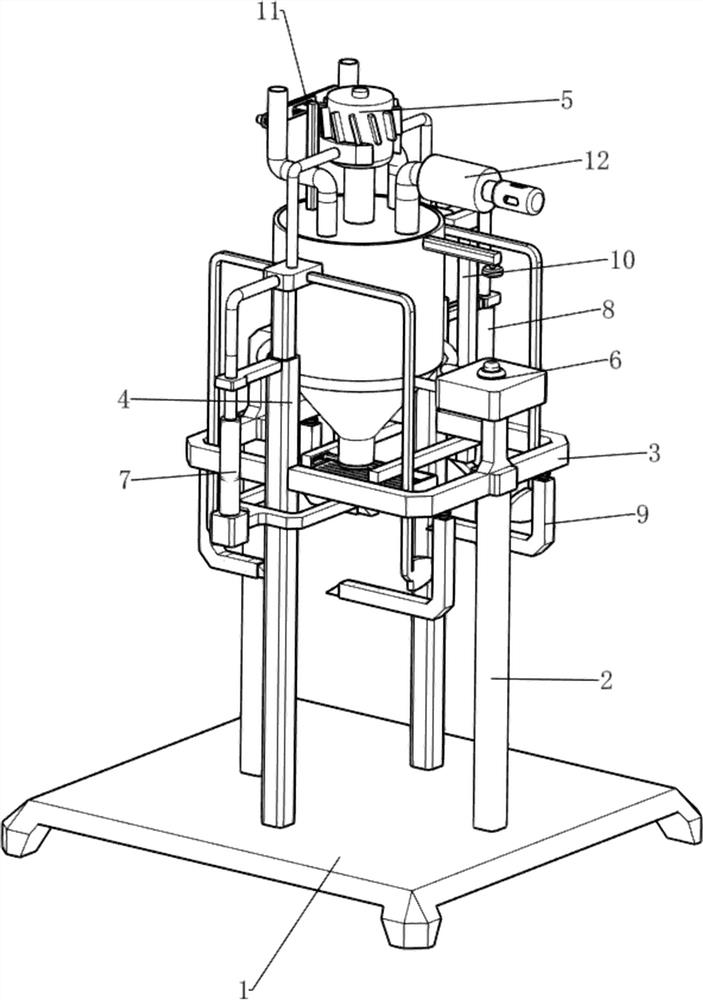

[0072] A rare metal replacement equipment for rare earth industry, such as Figure 1-2 As shown, it includes a bottom plate 1, a strut 2, a frame 3, a gravity mechanism 4 and a mixing mechanism 5. The top of the bottom plate 1 is provided with two struts 2, the top of the bottom plate 1 is provided with a gravity mechanism 4, and the upper part of the strut 2 is A frame 3 is connected between the 4 components of the gravity mechanism, and a mixing mechanism 5 is arranged on the components of the gravity mechanism 4. The gravity mechanism 4 includes a first set of rods 41, a first spring 42, a first connecting rod 43, and a first connecting block. 44 and the mixing bucket 45, two first sets of rods 41 are arranged on the top of the bottom plate 1, the upper parts of the first sets of rods 41 are all slidably connected with first connecting rods 43, and the bottoms of the first connecting rods 43 are connected with the first set of rods on the same side. A first spring 42 is conne...

Embodiment 2

[0076] On the basis of Example 1, as Figure 3-10 As shown, it also includes a heating mechanism 6, the heating mechanism 6 includes a pressure rod 61, a point control switch 62 and a resistance wire 63, the upper front side of the mixing barrel 45 is provided with a pressure rod 61, and the front side of the top of the frame 3 on the front side is provided with a pressure rod 61. There is a point control switch 62 , two resistance wires 63 are connected between the rear side of the point control switch 62 and the front side of the upper part of the frame 3 on the rear side, and the resistance wires 63 are respectively located outside the mixing barrel 45 .

[0077] When people put rare earths, special liquids and metal elements into the mixing barrel 45, the mixing barrel 45 slowly moves down due to gravity, which in turn drives the pressure rod 61 to move down. When the 62 contacts, the point control switch 62 is turned on, so that the resistance wire 63 starts to heat up to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com