Textile with contact cold feeling and preparation method thereof

A technology for textiles and cold feeling, which is applied in the direction of textiles and paper making, which can solve the problems of not very strong cold feeling, slow heat transmission, small contact area between fabrics and skin, etc., to achieve good cold feeling sustainability, low production cost, The effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The present invention also provides a preparation method for the above-mentioned cool slurry, comprising the following steps:

[0045] S1. Stir the adhesive of the formula amount, add the PCM phase change energy storage capsule of the formula amount into the adhesive, and continue stirring to obtain the mixed solution 1;

[0046] S2. Add the cooling factor of the formula amount to the mixed solution obtained in step S1, and continue stirring to obtain the mixed solution 2;

[0047] S3. Add deodorant, antifungal agent and softener in the formula quantity to the mixed solution 2 obtained in step S2, and stir; or continue to add thickener, anti-blocking agent, water in the formula quantity after stirring, and stir to obtain The cool slurry.

[0048] Preferably, the agitation in step S1 is 300-500 rpm.

[0049] The present invention also provides the application of the above-mentioned cooling paste in the preparation of textiles with contact cooling and continuous cooling...

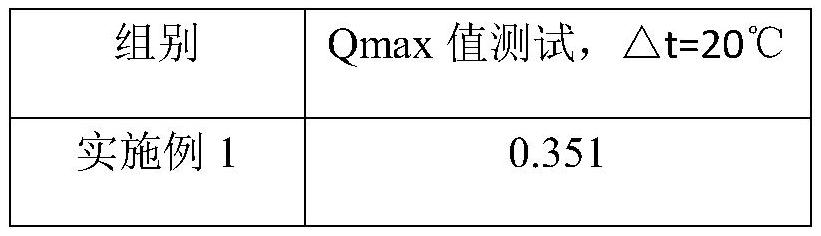

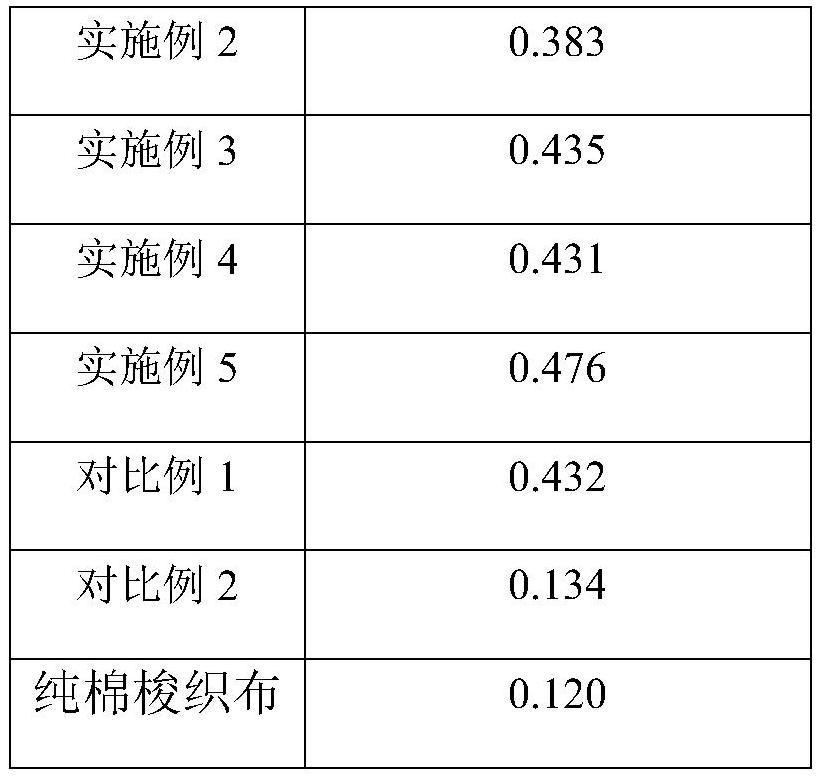

Embodiment 1-5

[0063] Embodiment 1-5 A kind of cool slurry and its textiles with contact cool feeling and continuous cool feeling and its preparation method

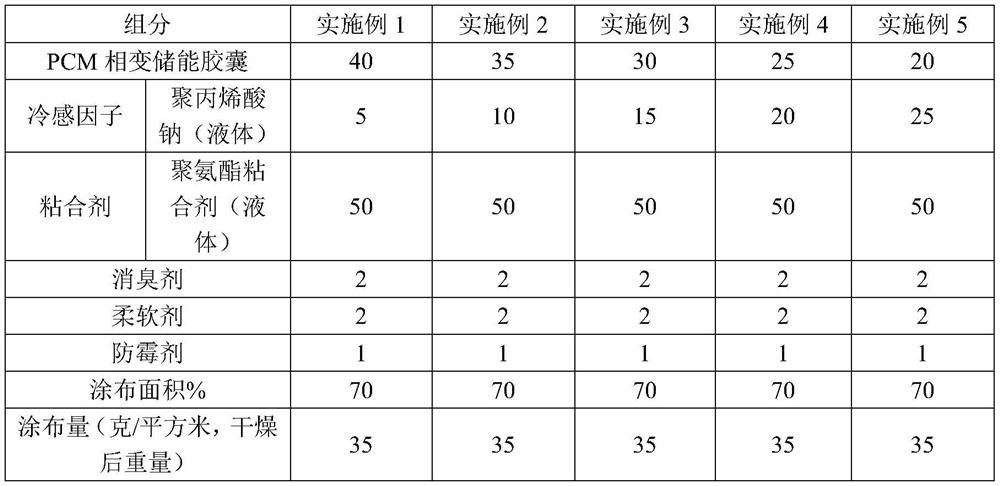

[0064] The coating area of cooling slurry and textiles in Examples 1-5 is shown in Table 1. The fabric used is pure cotton woven fabric with a yarn count of 60S*40S and a density of 172*120.

[0065] Table 1

[0066]

[0067] The preparation method of the cool slurry is:

[0068] S1. Pour the formulated amount of adhesive into the mixing tank, turn on the low speed, stir at a speed of 300-500rpm, add the formulated amount of PCM phase change energy storage capsules into the adhesive, and stir for 10 minutes to obtain a mixed solution 1;

[0069] S2. Add the cooling factor of the formula amount to the mixed solution obtained in step S1, and continue to stir for 5 minutes to obtain the mixed solution 2;

[0070] S3. Add the deodorant, anti-fungal agent and softener in the formulated amount to the mixed liquid 2 obtained in step S...

Embodiment 6-10

[0086] Example 6-10 A kind of cold feeling pulp and its textiles with contact cold feeling and continuous cold feeling and its preparation method

[0087] The coating area of cooling slurry and textiles in Examples 6-10 is shown in Table 3, and the fabric adopted is pure viscose non-woven fabric, 50 grams per square meter.

[0088] table 3

[0089]

[0090] The preparation method of the cool slurry is:

[0091] S1. Pour the formulated amount of adhesive into the mixing tank, turn on the low speed, stir at a speed of 300-500rpm, add the formulated amount of PCM phase change energy storage capsules into the adhesive, and stir for 10 minutes to obtain a mixed solution 1;

[0092] S2. Add the cooling factor of the formula amount to the mixed solution obtained in step S1, and continue to stir for 5 minutes to obtain the mixed solution 2;

[0093] S3. Add the deodorant, anti-fungal agent and softener in the formulated amount to the mixed liquid 2 obtained in step S2, and sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com