Pearl cloth with special smooth surface

A special glossy surface and pearl technology, which is applied to devices that apply liquid to the surface, textiles, papermaking, coatings, etc., and can solve the problems of inability to prevent cutting, poor flame retardant effect, and shortening the service life of pearl cloth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

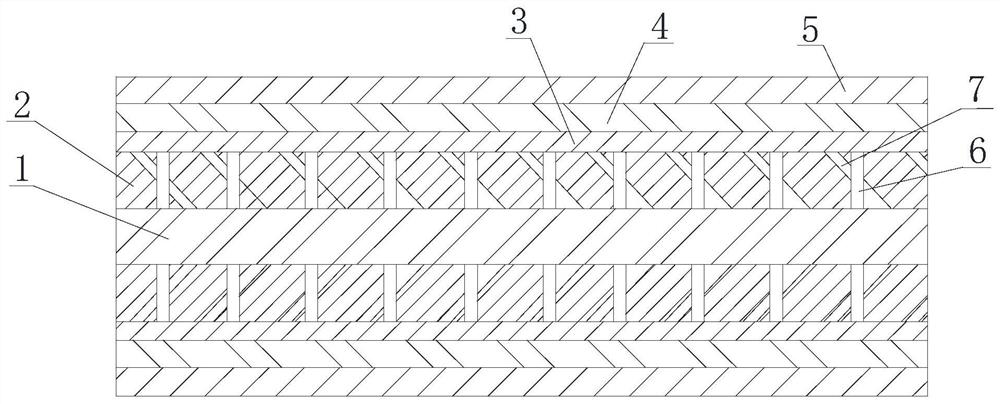

[0038] A special glossy pearl cloth, refer to Figure 1-4 , which includes a pearl cloth body 30, the pearl cloth body 30 includes a pearl cotton layer 1, two pearl cotton layers 2 arranged symmetrically up and down on the pearl cotton layer 1, and a BOPP mold layer arranged on the pearl cotton layer 2 3. The flame-retardant layer 4 arranged on the BOPP mold layer 3 helps to improve the stretching effect of the pearl cloth body 30 by setting the BOPP mold layer 3; the pearl cotton layer 2 is provided with a number of cross-woven fabrics. High-strength and high-model polyethylene fibers 6 and some spandex fibers 7 improve the strength of the pearl cloth body 30 while improving the anti-cutting ability to prevent external hard objects from piercing the pearl cloth body 30; Raw materials: 55-75 parts of flame retardant, 8-17 parts of foaming agent, 28-52 parts of textile emulsion, 38-62 parts of foam stabilizer, 1-11 parts of talcum powder, 2-6 parts of anti-UV agent, antistatic ...

Embodiment 2

[0043] A special glossy pearl cloth, refer to Figure 1-4 , which includes a pearl cloth body 30, the pearl cloth body 30 includes a pearl cotton layer 1, two pearl cotton layers 2 arranged symmetrically up and down on the pearl cotton layer 1, and a BOPP mold layer arranged on the pearl cotton layer 2 3. The flame-retardant layer 4 arranged on the BOPP mold layer 3 helps to improve the stretching effect of the pearl cloth body 30 by setting the BOPP mold layer 3; the pearl cotton layer 2 is provided with a number of cross-woven fabrics. High-strength and high-model polyethylene fibers 6 and some spandex fibers 7 improve the strength of the pearl cloth body 30 while improving the anti-cutting ability to prevent external hard objects from piercing the pearl cloth body 30; Raw materials: 55-75 parts of flame retardant, 8-17 parts of foaming agent, 28-52 parts of textile emulsion, 38-62 parts of foam stabilizer, 1-11 parts of talcum powder, 2-6 parts of anti-UV agent, antistatic ...

Embodiment 3

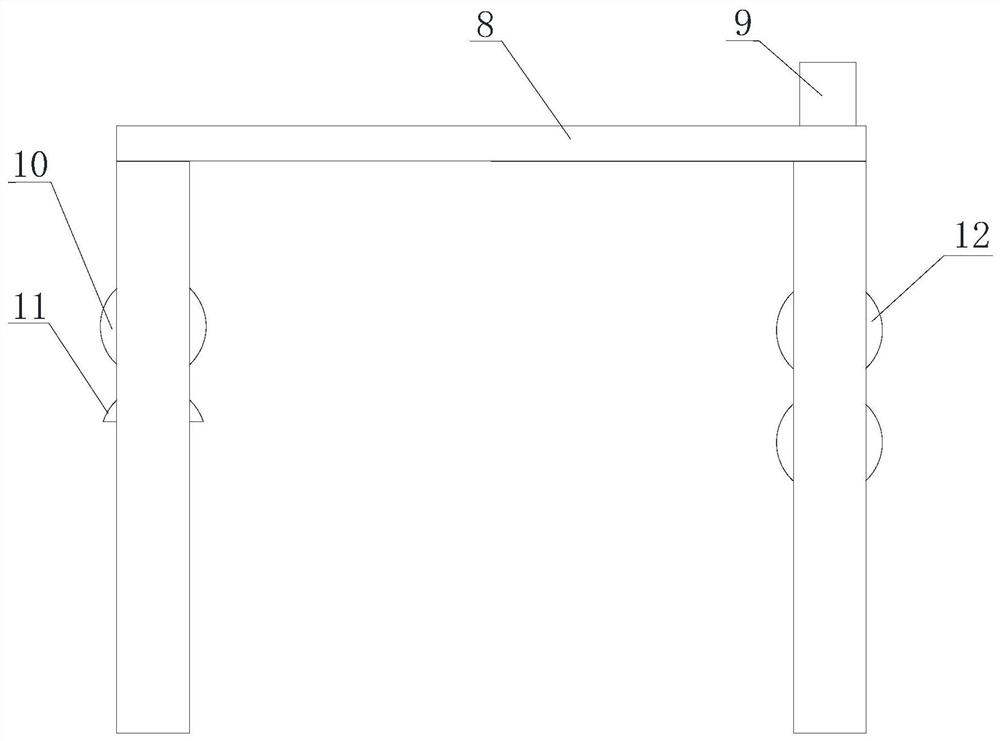

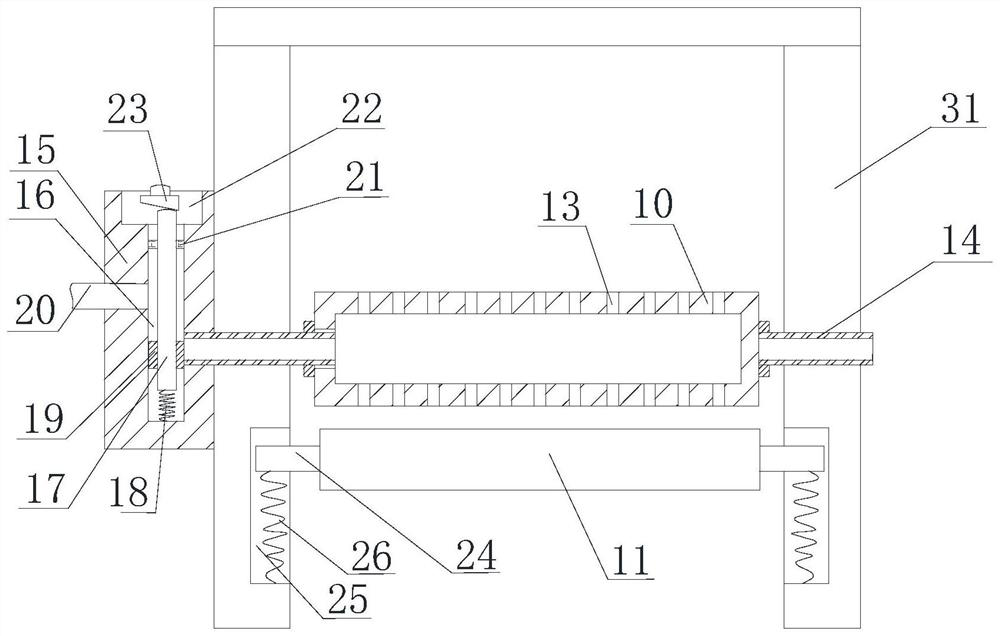

[0048] The invention also discloses a coating device suitable for pearl cloth with special light surface, referring to Figure 1-4 , which includes a bracket 8, a coating component arranged at the left end of the inner side of the bracket 8, an extruding and conveying component arranged at the right end of the inner side of the bracket 8 and matched with the coating component, and the coating component includes front and rear symmetrically penetrating through the front and rear sides of the bracket 8. The cylinder 14 on the side, the coating roller 10 that is rotatably connected between the two cylinders 14, a number of output holes 13 that are evenly opened on the outer side wall of the coating roller 10, are arranged on the front side of the bracket 8 and are located in the front cylinder. The fixed block 15 matched with the body 14, the groove 22 set on the top of the fixed block 15, the installation cavity 16 set on the inner bottom of the groove 22, is arranged on the inne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com