Structure and method for additionally installing balance block on fan coupler

A technology of couplings and balance weights, which is applied to machines/engines, components of pumping devices for elastic fluids, mechanical equipment, etc., can solve the problems of long time for adding balance weights and heavy on-site workload, and achieve Save time and labor costs, ensure safety, and reduce on-site workload

Pending Publication Date: 2021-09-07

XIAN THERMAL POWER RES INST CO LTD

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] Aiming at the problems of long installation of balance blocks and heavy on-site workload for the existing fan of the power station, and considering the conventional structure of the fan and on-site conditions, and on the premise of reducing the on-site workload and working time as much as possible, the present invention proposes an on-site The Structure and Method of Adding Balance Weight to Fan Coupling

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0036] The flue gas system of a 1000MW unit in China is equipped with two induced draft fans. After starting up, it was found that the horizontal vibration of the fans was too large, and the vertical and axial vibrations were normal. After on-site measurement, the horizontal vibration velocity of the bearing at the motor drive end exceeds 6mm / s, with double frequency as the main frequency. Analysis of this problem is a typical dynamic balance problem, and it is planned to solve it by adding a balance weight.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Login to view more

Abstract

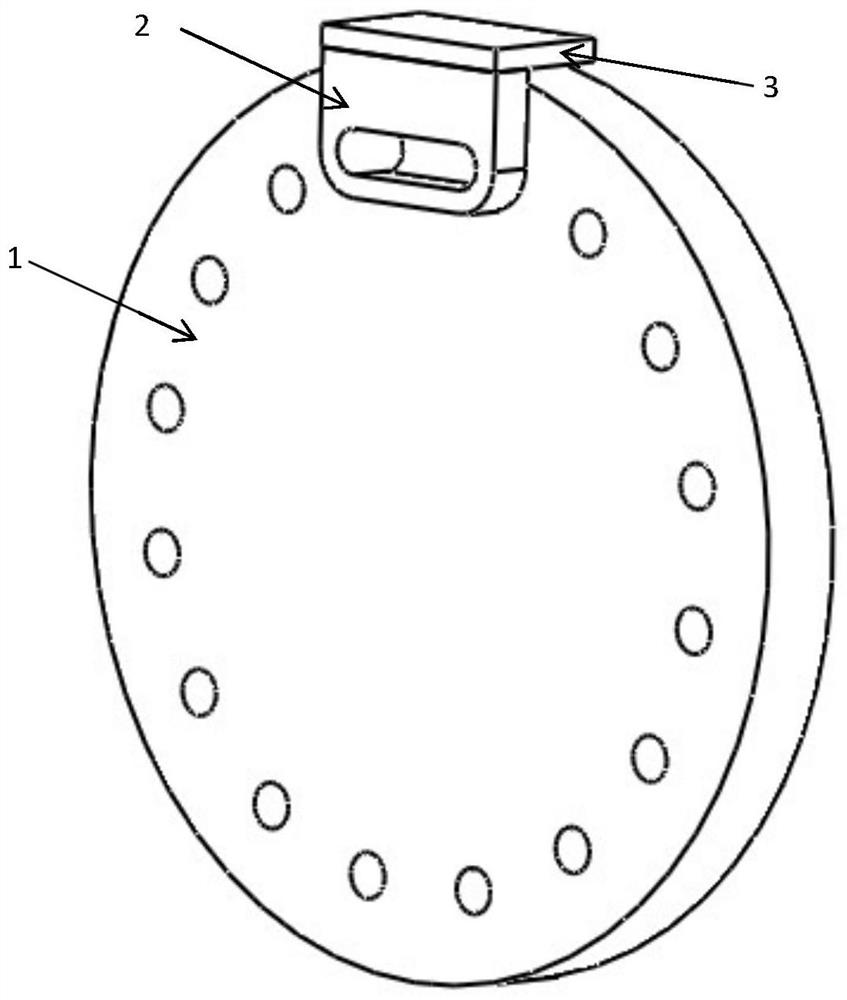

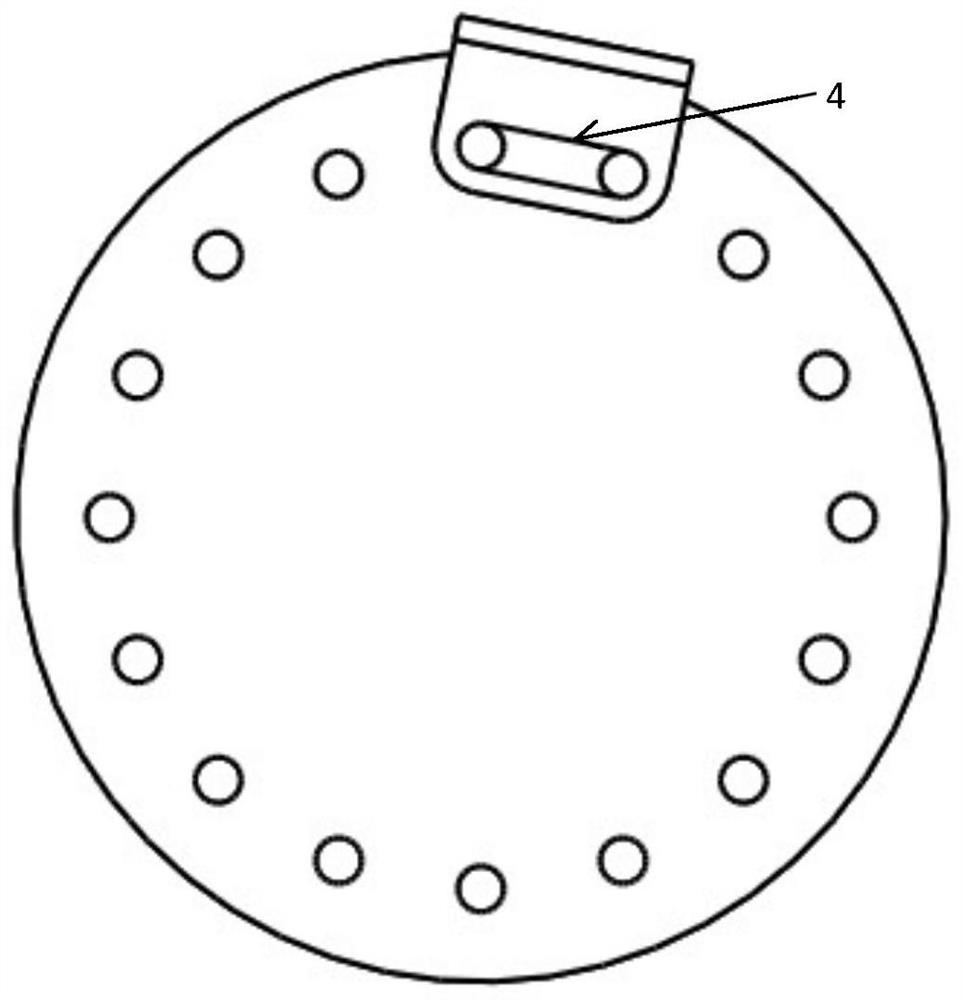

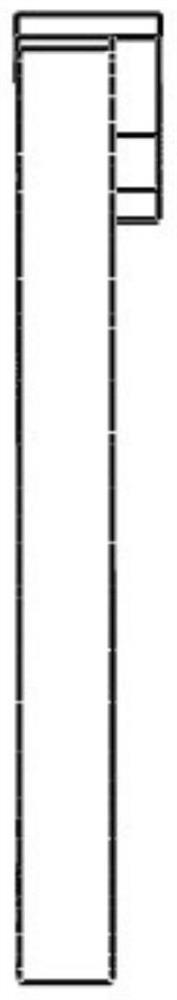

The invention provides a structure and a method for additionally installing a balance block on a fan coupler. The structure comprises a reinforcing disc and the balance block, the reinforcing disc is fixed to the coupler through bolts, and the balance block is fixed to the reinforcing disc and the coupler in a welded mode. The method comprises the steps that the reinforcing disc is machined according to the structure of the coupler, and a circular ring hollow structure on the disc is basically the same as a bolt hole of the coupler in size; the balance block is machined according to vibration data, the weight of a weight test block is estimated according to the vibration data, the radius of a rotor and the mass, and the machined balance block and the reinforcing disc are matched and welded to the corresponding position of the rotor; the angle and the weight are adjusted, counterweight is carried out, and a complete process of dynamic balance is completed; and if the vibration data still exceed the standard after the counterweight is completed, the previous steps are continuously repeated. The balance block is additionally arranged on an original coupler structure, safety is guaranteed through the two methods that the balance block and the coupler are welded and the balance block and the coupler are fixed through bolts, and the balance block is prevented from being thrown out.

Description

technical field [0001] The invention belongs to the field of coal-fired thermal power plants, and in particular relates to a structure and method for adding a balance block to a fan shaft coupling. Background technique [0002] There are many types of fans in thermal power plants: such as induced draft fans, supply fans, primary fans, sealed fans, etc. These are important equipment for thermal power plants. At present, the total power consumption of fans in power plants in my country accounts for more than 30% of the power consumption rate of power plants. Obviously, the safety, reliability and operation economy of boiler fans in thermal power plants are extremely important to the safety and economy of power plants. [0003] The most common cause of fan vibration during actual operation is dynamic imbalance, and it is necessary to install a balance block on the fan. The most common place to add the balance weight is the impeller of the fan. Not only does the fan need to be...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more IPC IPC(8): F04D29/66F04D29/054

CPCF04D29/662F04D29/668F04D29/054

Inventor 李昊燃郑金孙大伟闫宏王星石清鑫马翔陈得胜王伯平

Owner XIAN THERMAL POWER RES INST CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap