A Clay Mineral Oriented Sheet Atomization Treatment Device and Treatment Method

A clay mineral and processing device technology, applied in the field of atomization processing devices, can solve problems such as XRD analysis errors, achieve the effects of reducing sample errors, improving experimental testing efficiency, and protecting health and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

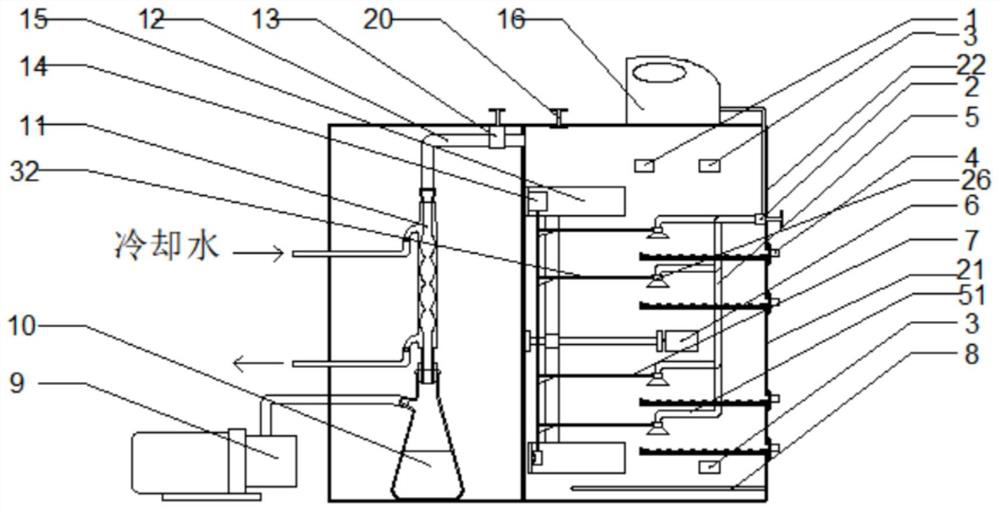

[0094] Such as Figure 1-Figure 3 As shown, a clay mineral directional sheet atomization treatment device, the device as a whole adopts a full set of corrosion-resistant materials, including an atomization box 22, which is a fully airtight sealed box, and an atomizer 16 is arranged outside the atomization box 22 The atomization box 16 is provided with a sensor and a spray assembly. The sensor includes an air pressure sensor 1 and a temperature sensor 3. The air pressure sensor 1 and the temperature sensor 3 are arranged on the upper part of the atomization box 22 for controlling the air pressure and temperature in the atomization box. . One end of the spray assembly is horizontally arranged in the atomization box 16, and the other end extends to the outside of the atomization box 16. The spray assembly can change the position of the spray through the servo motor and the moving assembly to realize horizontal and vertical movement of the spray in the same plane. Shower, the bot...

Embodiment 2

[0112] A method for atomizing the directional sheet of clay minerals, which is carried out using the processing equipment in Example 1, specifically comprising the following steps:

[0113] (1), first check the airtightness of the atomization treatment device: insert the empty drawer 4 directly into the atomization box 22, close the conduit valve 2 and the air release valve 20, turn on the vacuum pump 9, and open the exhaust pipe valve 13, do not need to open Cooling water, pump the inside of the atomization box 22 into a negative pressure, then close the exhaust pipe valve 13, turn off the vacuum pump 9, observe the reading of the air pressure sensor 1, the vacuum degree in the atomization box 22 remains unchanged, indicating that the airtightness is normal, then you can Normal use;

[0114](2), carry out organic solvent ethylene glycol, glycerin saturation treatment: put the oriented sheet 17 that is coated with clay mineral in the drawer 4, insert the drawer 4 into the atom...

Embodiment 3

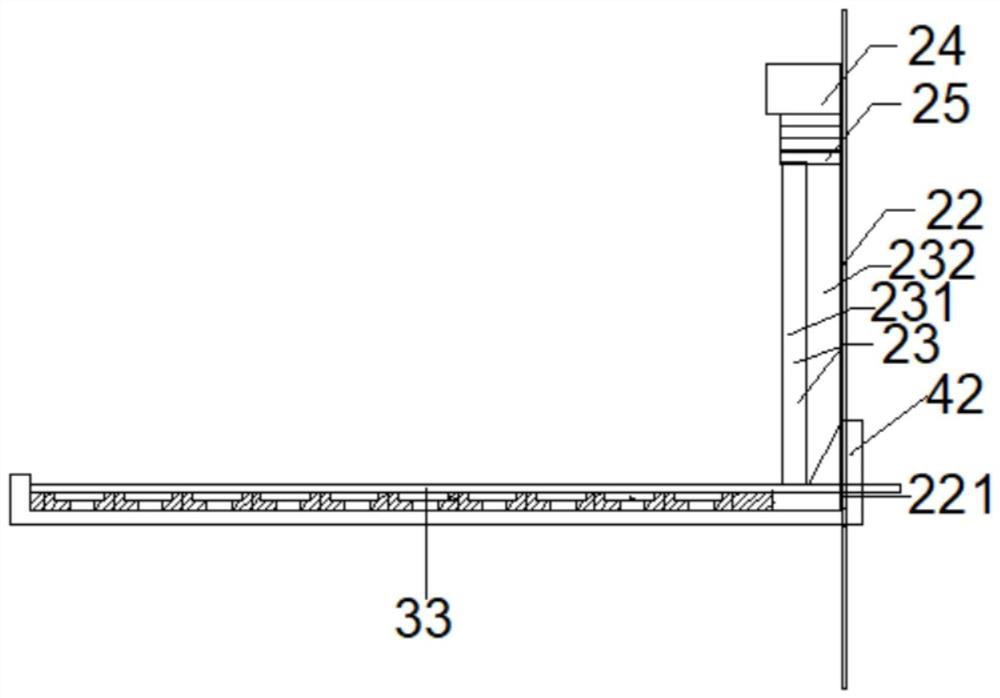

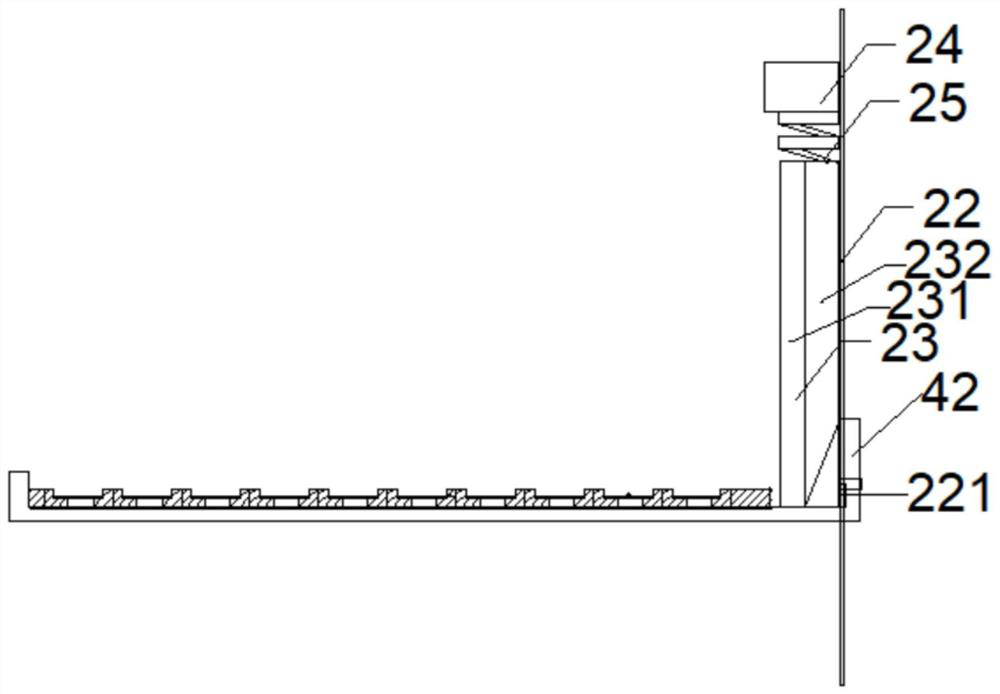

[0121] A kind of atomization treatment method of clay mineral orientation sheet, and embodiment 1 is similar, and difference is, as Figure 4 with Figure 5 As shown, a sealing block 43 is fixedly connected to the inner side of the sealing plate 42, the sealing block 43 is a right-angled triangle sealing block, and the outer surface of the sealing block 43 is inclined. Corresponding sockets are also provided at the corresponding positions of the sealing block 43 and the sealing plate 42 to facilitate the insertion of the cover plate. A movable baffle assembly 23 is provided on the inner side of the box wall of the atomization box 22 located on the upper part of the sealing block 43 . The movable baffle assembly includes an inner baffle 231 and an outer baffle 232, and the inner baffle 231 and the outer baffle 232 are arranged separately. The inner layer baffle plate 231 and the outer layer baffle plate 232 are adjacent and arranged in parallel. The inner layer baffle plate 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com