Spot-size converter and silicon optical integrated chip

An integrated chip and converter technology, applied in the field of optical communication, can solve the problems of large wedge-shaped structure loss, large polarization-dependent loss, and large polarization-dependent loss of mode spot converter.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

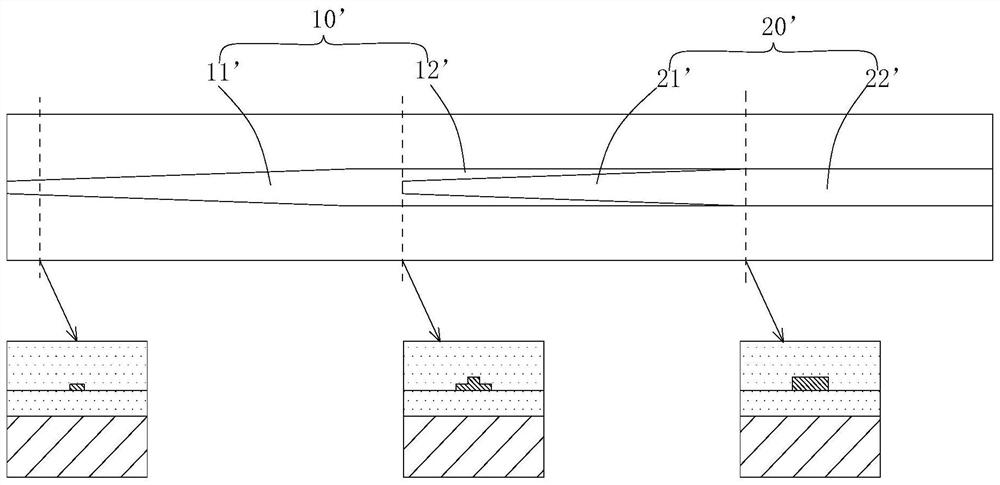

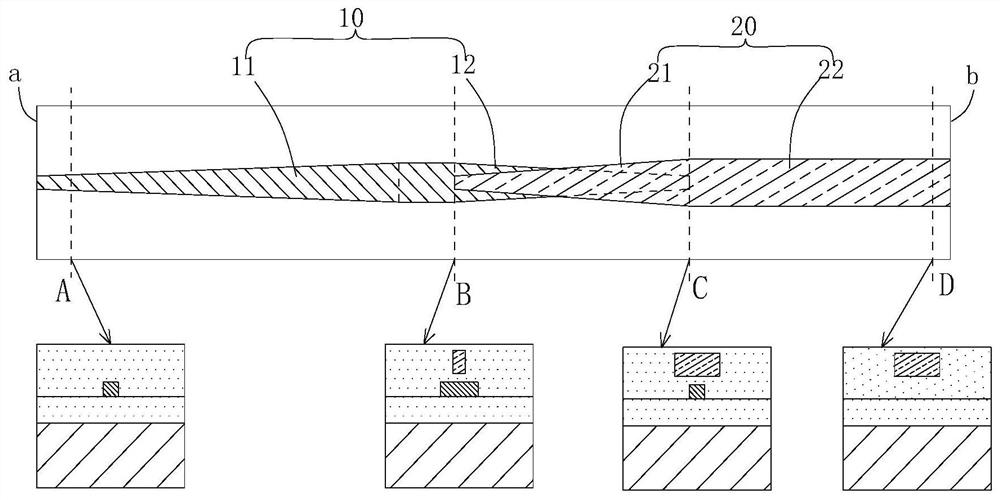

[0036] Such as image 3 and 4, this embodiment provides a mode spot converter, which has a first end face a optically coupled with an external optical fiber and a second end face b optically coupled with an external optical device, the mode spot converter includes a first optical waveguide 10 and a second optical waveguide Two optical waveguides 20 , the thickness of the first optical waveguide 10 is smaller than the thickness of the second optical waveguide 20 . Wherein, the first optical waveguide 10 includes a first wedge-shaped structure 11 and a second wedge-shaped structure 12, the tip of the first wedge-shaped structure 11 is close to the above-mentioned first end face a, and the tip of the second wedge-shaped structure 12 faces to the edge of the first wedge-shaped structure 11. Orientation of the tips facing away from each other. Here, the tip of the first wedge-shaped structure 11 is close to the above-mentioned first end face a, which means that the tip of the fir...

Embodiment 2

[0040] Such as Figure 5 As shown, the difference from Embodiment 1 is that the second optical waveguide 20 of the speckle converter in this embodiment adds an edge coupling structure 23, and one end of the edge coupling structure 23 is connected to the tip of the third wedge-shaped structure 21, and the other One end deviates from the central axis of the second optical waveguide 20 and extends toward the edge of the first optical waveguide 10 to better adiabatically couple the optical modes in the first optical waveguide 10 into the second optical waveguide 20 .

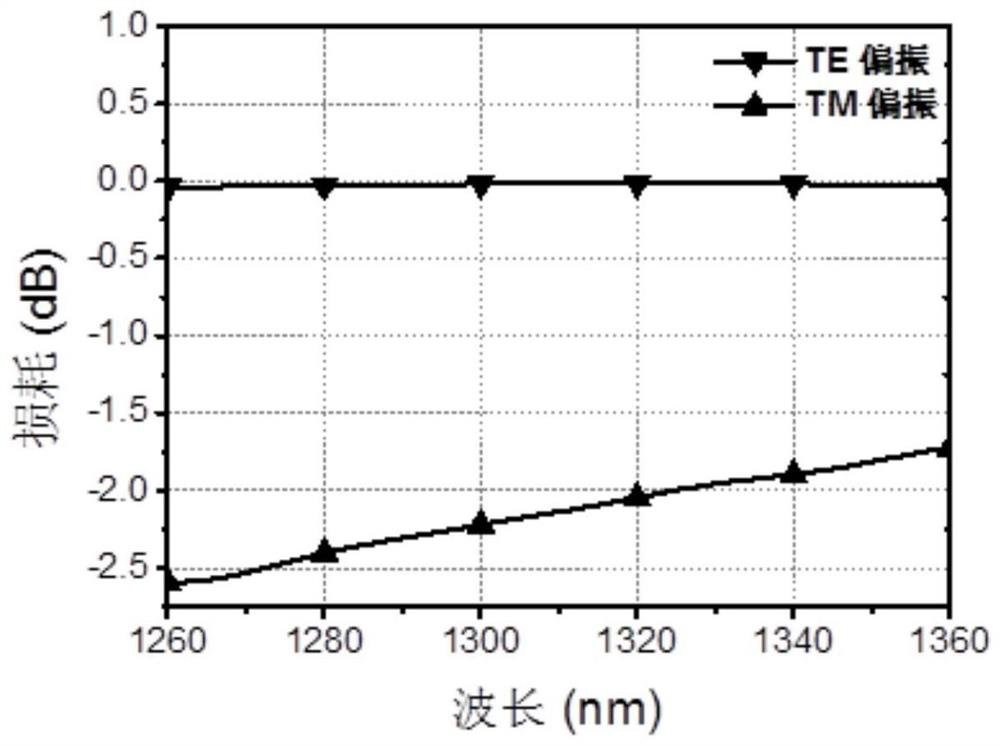

[0041] In the speckle converter of Embodiment 1, in order to reduce the polarization-dependent loss between the first optical waveguide 10 and the second optical waveguide 20 as much as possible, the tip size of the third wedge-shaped structure 21 of the second optical waveguide 20 needs to be made to be as small as possible, but limited by the semiconductor processing technology, the tip of the third wedge-shaped s...

Embodiment 3

[0044] Such as Figure 7 As shown, the difference from Embodiments 1 and 2 is that the first end face a of the speckle converter in this embodiment is provided with a hollowed out portion 40 at the substrate 31 of the lower cladding layer 32 under the first optical waveguide 10 , for example, a hollow portion 40 can be etched on the end face a of the substrate 31 by using a wet etching process, so as to bind the light beams in the upper cladding layer 34, the lower cladding layer 32 and the first optical waveguide 10, and avoid external optical fiber The light coupled to the first optical waveguide 10 enters the substrate 31 and is radiated and lost from the substrate, thereby further improving the coupling efficiency between the external optical fiber and the mode-spot converter.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com