Heating method for detonation pipeline

A heating method and pipeline technology, applied in ohmic resistance heating parts, instruments, control/regulation systems, etc., can solve the problems of cumbersome, uneven heating, slow heating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

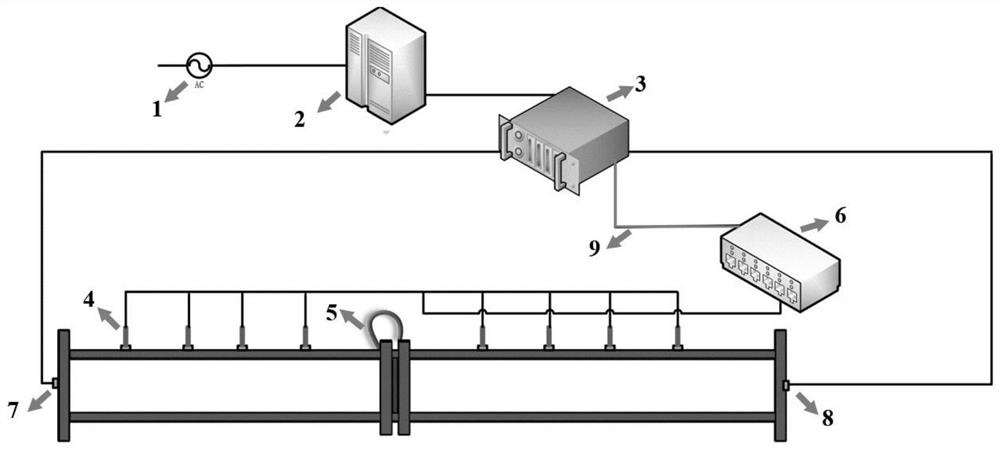

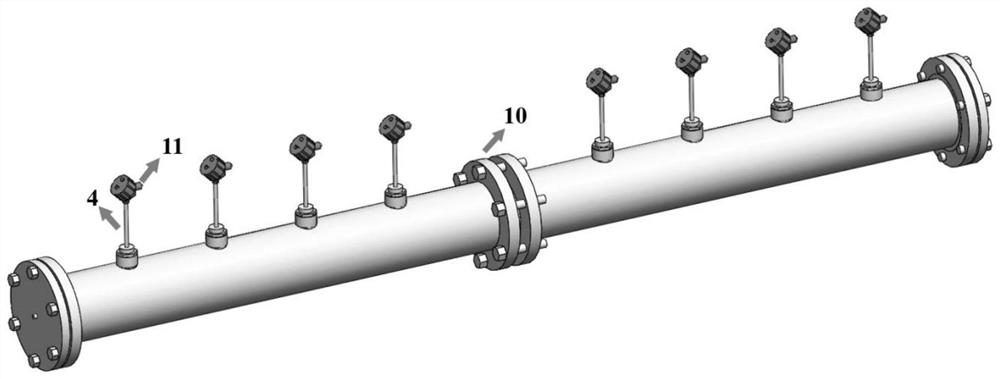

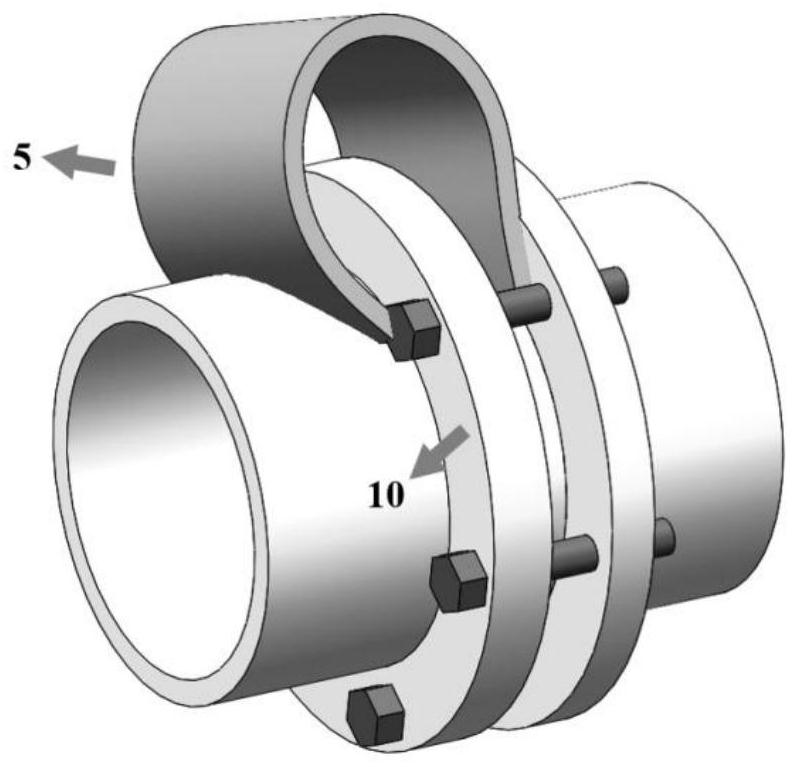

[0027] A detonation tube with a diameter of 48 mm and a length of 4 meters is selected, and 8 thermocouple sensor interfaces are arranged above the tube. refer to figure 1 , After assembling the heating system, inject a certain volume of liquid fuel into the pipeline, set the preset temperature of the temperature measuring and controlling instrument to 100°C, set the output voltage of the constant voltage source to 5V, and turn on the power.

Embodiment 2

[0029] A detonation tube with a diameter of 48 mm and a length of 4 meters was selected. Follow the same steps to assemble the heating system, adjust the preset temperature of the temperature measuring and controlling instrument to 100°C, increase the output voltage of the constant voltage source to 15V, and turn on the power.

Embodiment 3

[0031] A detonation tube with a diameter of 20 mm and a length of 8 m was selected. Set the preset temperature of the temperature measuring and controlling instrument to 100°C, and set the output voltage of the constant voltage source to 15V.

[0032]After the pipelines of the above three embodiments are heated for 60s, the temperature of different channels displayed by the temperature is summarized in Table 1:

[0033]

[0034] Table 1 Unit: °C

[0035] From the data collected in the embodiment of the present invention, it can be seen that the heating uniformity of the heating method for the detonation pipeline is very good, and the temperature difference between different parts of the pipeline is extremely small; It can be heated to the preset temperature by left or right, so that the liquid fuel can be vaporized evenly and quickly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com