Lithium lanthanum zirconium tantalum oxide solid electrolyte and preparation method and application thereof

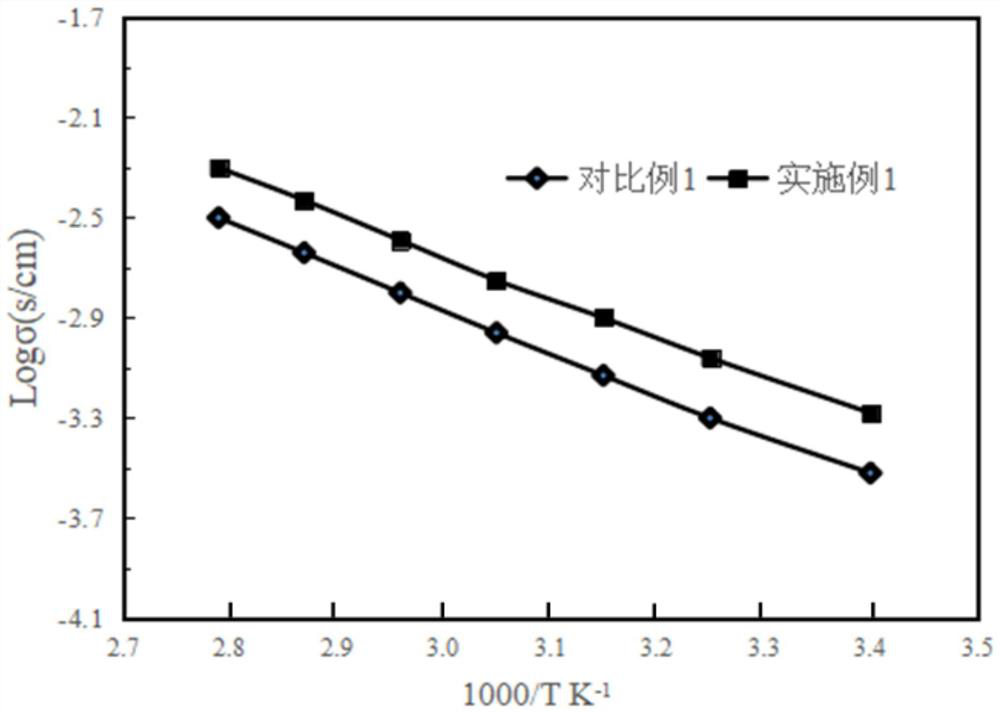

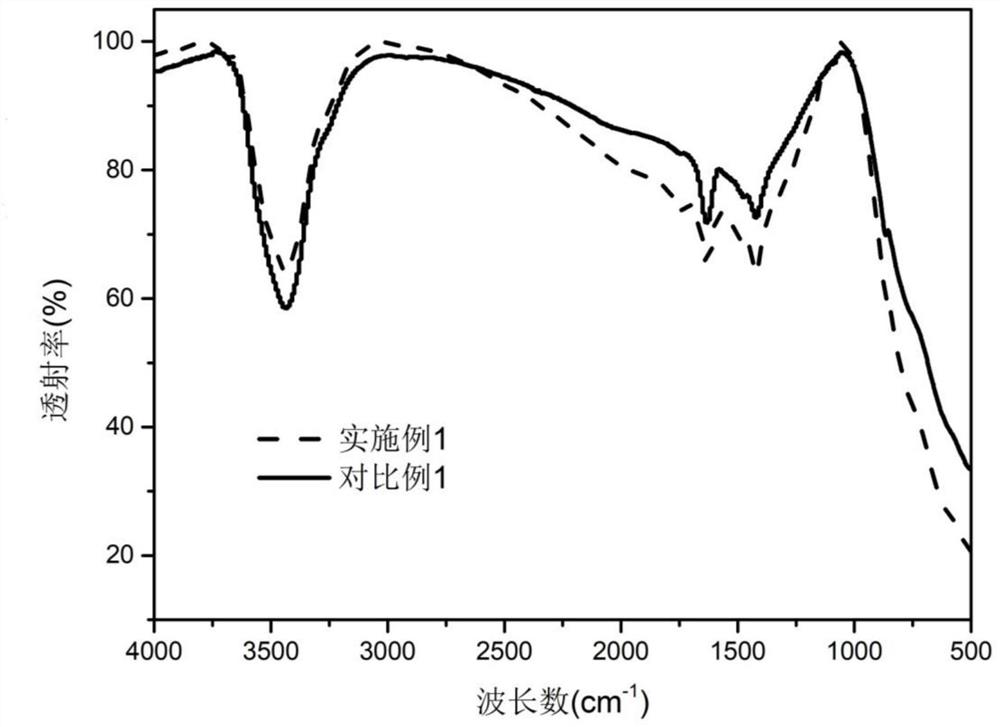

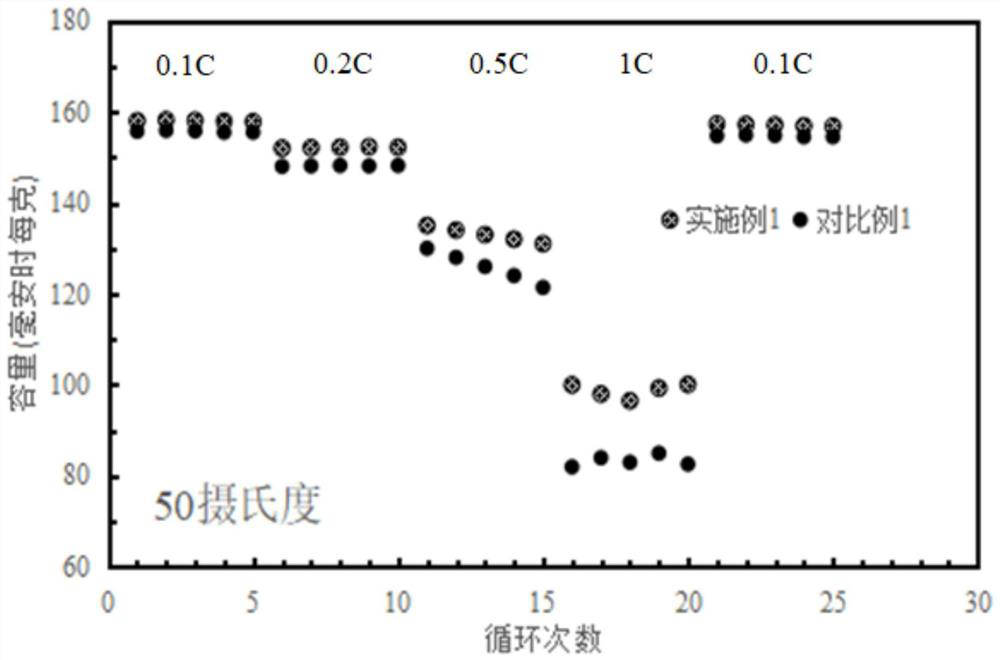

A solid electrolyte, lithium lanthanum zirconium technology, applied in electrolytes, non-aqueous electrolyte battery electrodes, electrolyte immobilization/gelation and other directions, can solve the problems of impurities in lithium lanthanum zirconium tantalum oxygen and affect the use of solid electrolytes, and achieve electrical conductivity. The effect of increasing the rate and improving the performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] In this example, lithium lanthanum zirconium tantalum oxygen solid electrolyte was prepared according to the following method:

[0063] Lithium source (lithium hydroxide), zirconium source (zirconia), lanthanum source (lanthanum oxide), tantalum source (tantalum oxide), sintering aid (alumina) and first solvent (isopropanol) were sand milled and mixed ( The mass ratio of lithium source, lanthanum source, zirconium source, tantalum source and sintering aid is 19.6:32:14.1:7.2:1, and the total mass of lithium source, zirconium source, lanthanum source, tantalum source and sintering aid is the same as described The mass ratio of the first solvent is 0.5:1. After spray drying, sintering is carried out. The sintering temperature is 900°C, and the sintering time is 8h. The obtained sintered product is stirred and dispersed with the second solvent (ethanol) and the ceramic membrane is washed and purified. (the pore diameter of the ceramic membrane tube is 50nm, and the mass ra...

Embodiment 2

[0074] In this example, lithium lanthanum zirconium tantalum oxygen solid electrolyte was prepared according to the following method:

[0075] Lithium source (lithium hydroxide), zirconium source (zirconia), lanthanum source (lanthanum oxide), tantalum source (tantalum oxide), sintering aid (alumina) and first solvent (isopropanol) were sand milled and mixed ( The mass ratio of lithium source, lanthanum source, zirconium source, tantalum source and sintering aid is 20.4:32:14.1:3.6:1, and the total mass of lithium source, zirconium source, lanthanum source, tantalum source and sintering aid is the same as described The mass ratio of the first solvent is (0.2:1), sintering is carried out after spray drying, the sintering temperature is 850°C, and the sintering time is 9h, and the obtained sintered product is stirred and dispersed with the second solvent (N-methylpyrrolidone) Wash and purify the ceramic membrane (the pore diameter of the ceramic membrane tube is 10nm, the mass r...

Embodiment 3

[0085] In this example, lithium lanthanum zirconium tantalum oxygen solid electrolyte was prepared according to the following method:

[0086] Lithium source (lithium hydroxide), zirconium source (zirconia), lanthanum source (lanthanum oxide), tantalum source (tantalum oxide), sintering aid (alumina) and first solvent (isopropanol) were sand milled and mixed ( The mass ratio of lithium source, lanthanum source, zirconium source, tantalum source and sintering aid is 18.9:2:14.1:10.8:1, and the total mass of lithium source, zirconium source, lanthanum source, tantalum source and sintering aid is the same as described The mass ratio of the first solvent is 0.7:1), and sintering is carried out after spray drying, the sintering temperature is 950°C, and the sintering time is 7h, and the obtained sintered product is mixed with the second solvent (isopropanol and N,N-dimethylformamide) was stirred and dispersed and washed and purified by ceramic membrane (the pore size of the ceramic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com