Rotor auxiliary slot optimization design method for reducing vibration noise of built-in permanent magnet motor

A vibration noise, permanent magnet motor technology, applied in synchronous motors with static armatures and rotating magnets, electric components, magnetic circuit rotating parts, etc., can solve the problem of sacrificing average torque, deteriorating vibration, poor universality, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

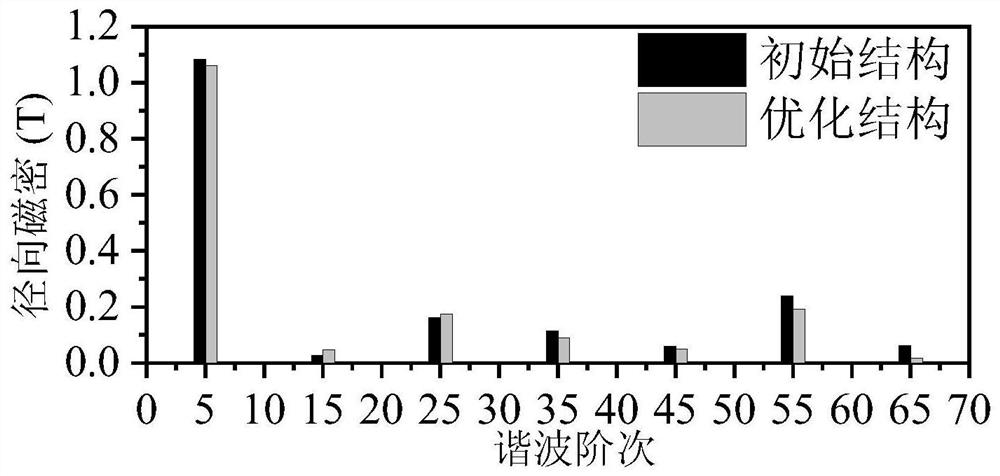

[0056] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention. In order to illustrate the beneficial effects of the present invention more simply and clearly, a detailed description will be given below in conjunction with a specific interior permanent magnet synchronous motor.

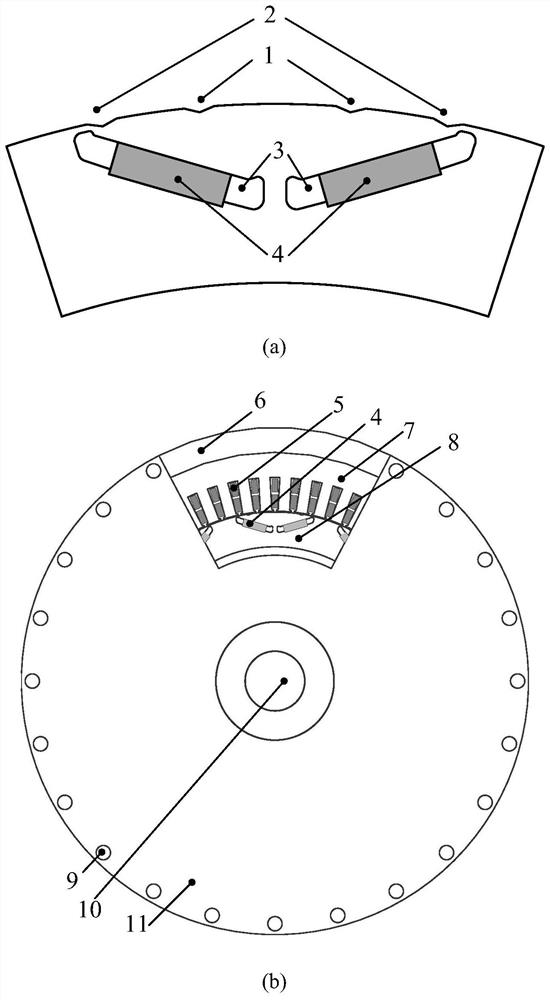

[0057] Step 1. First, according to the requirements of multiple operating conditions of the motor, determine the slot pole coordination, winding connection mode and rotor structure of the motor, that is, the integer slot distributed winding scheme and the single-layer V-shaped built-in permanent magnet structure;

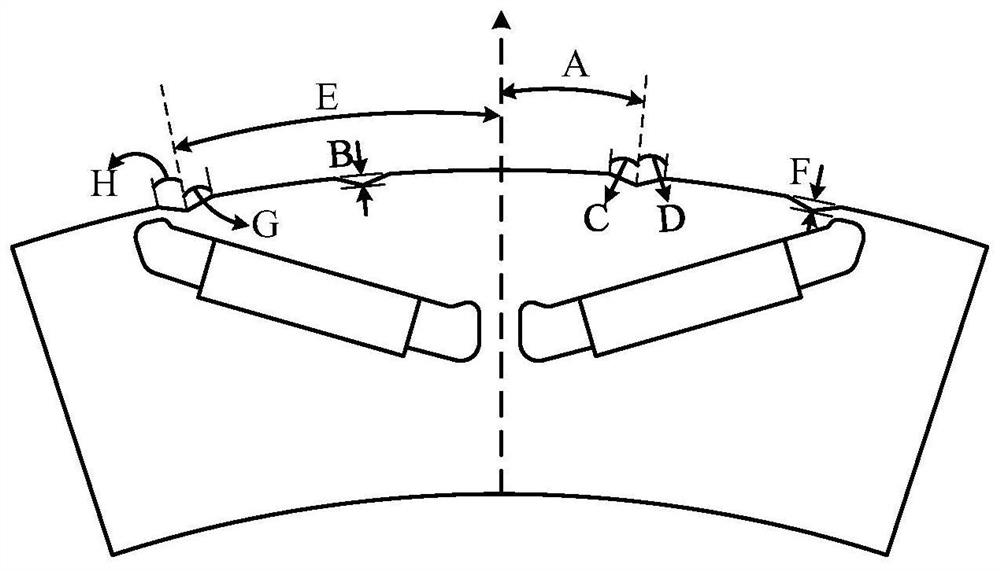

[0058] Determine the main structural parameters of the embodiment moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com