Preparation of vegetable oil gel fat substitute and application thereof in sausage

A technology of oil gel fat and fat substitute, applied in the direction of edible oil/fat, application, and oil-containing food ingredients, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0032] (1) Weigh 3g of ethyl cellulose and 50g of peanut oil, and mix them together.

[0033] (2) Heat the mixture obtained in step (1) at 220° C., and stir it with a constant magnetic force at a speed of 400 r / min until the ethyl cellulose is dissolved to obtain a reactant.

[0034] (3) The reactant obtained in the step (2) is cooled at 20° C. for 20 hours, and the obtained substance is the vegetable oil gel fat substitute.

preparation Embodiment 2

[0036] (1) Weigh 4g of ethyl cellulose and 50g of peanut oil, and mix them together.

[0037] (2) Heat the mixture obtained in step (1) at 200° C., and stir it with a constant magnetic force at a speed of 600 r / min until the ethyl cellulose is dissolved to obtain a reactant.

[0038] (3) The reactant obtained in the step (2) is cooled at 25°C for 30 hours, and the obtained substance is the vegetable oil gel fat substitute.

preparation Embodiment 3

[0040] (1) Weigh 5g of ethyl cellulose and 50g of peanut oil, and mix them together.

[0041] (2) Heat the mixture obtained in step (1) at 210° C., and stir it with a constant magnetic force at a speed of 500 r / min until the ethyl cellulose is dissolved to obtain a reactant.

[0042] (3) The reactant obtained in the step (2) is cooled at 20° C. for 24 hours, and the obtained substance is the vegetable oil gel fat substitute.

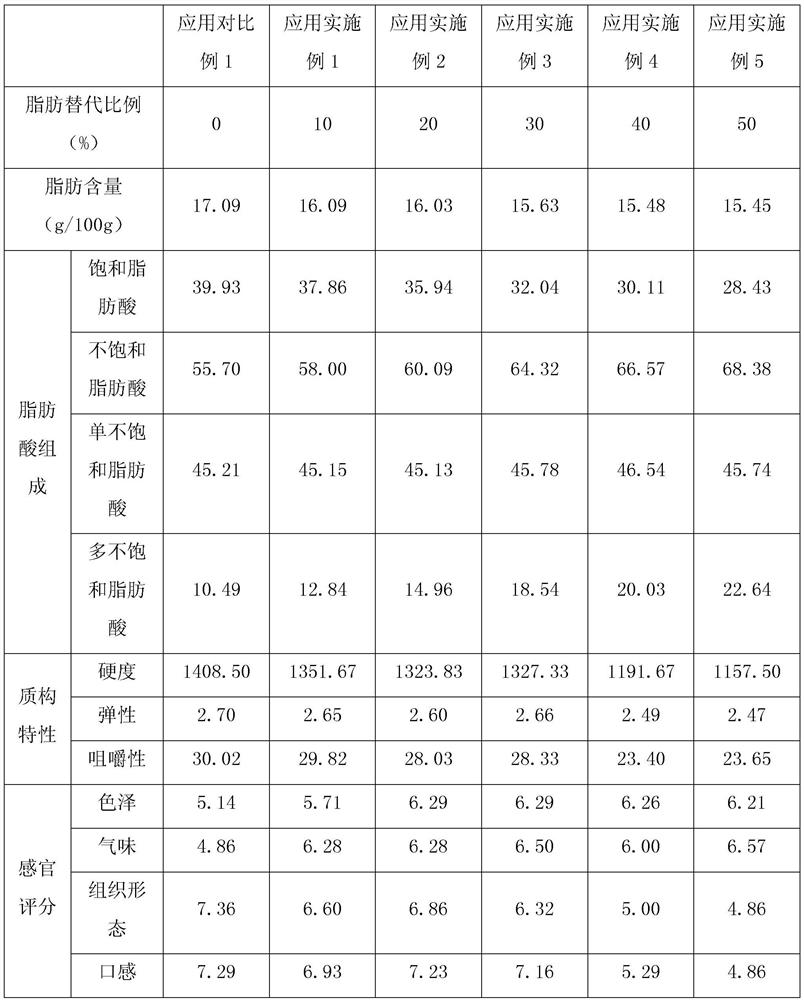

[0043] Test experiment:

[0044] For the fat substitutes prepared in Preparation Examples 1-3 above, their hardness and oil separation rate were tested, and the results are shown in Table 1. The specific test method is as follows:

[0045] Hardness: Cut vegetable oil gel grease substitute into 1cm 3 The cube was tested for hardness using a texture analyzer. The texture analyzer sets the parameters as probe P5, the pre-test rate: 2mm / s, the test rate is 1mm / s, and the post-test rate is 2mm / s. After the probe feels a force of 5.0g, it is pressed down b...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap