Automatic feeding and wire separating clamp for LED underwater lamp aluminum substrate wire welding

A technology of LED underwater lights and automatic feeding, applied in manufacturing tools, welding equipment, auxiliary welding equipment, etc., can solve the problems of low manufacturing cost efficiency, low threading efficiency, and non-universal fixtures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to enable those skilled in the art to better understand the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments:

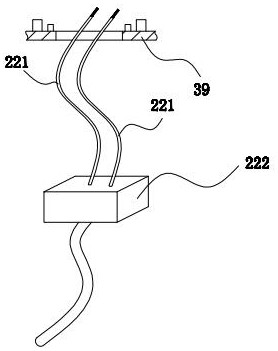

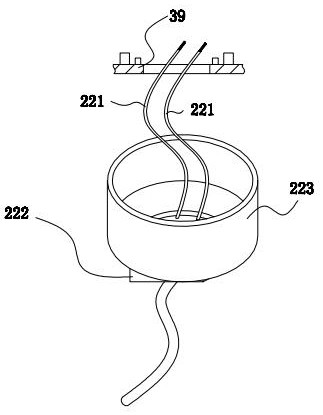

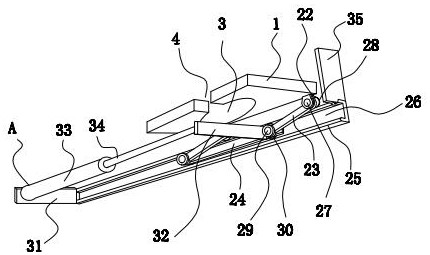

[0028] See attached Figures 3 to 10 , an automatic feeder branching fixture for LED underwater lamp aluminum substrate welding wire, comprising a clamp body 1, a clamping mechanism 2 located on the clamp body 1, a wire passing hole 3 located at the geometric center of the clamp body 1, and a clamp body located on the clamp body The pick-up channel 4 on 1, the pick-up channel 4 is connected with the wire-passing hole 3; it is characterized in that: the bottom plate surface of the clamp body 1 is provided with a driving mechanism A that drives it to move back and forth left and right, and when the wire-passing A wire branching mechanism B is arranged in the hole 3;

[0029] The line branching mechanism B includes a channel steel 5 again, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com