Automatic welding production line for pump shell press-fitting robot

A press-fitting production line and welding production line technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as inability to rotate the water pump for welding, inability to improve the efficiency of water pump welding, and pressure-fitting dislocation damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

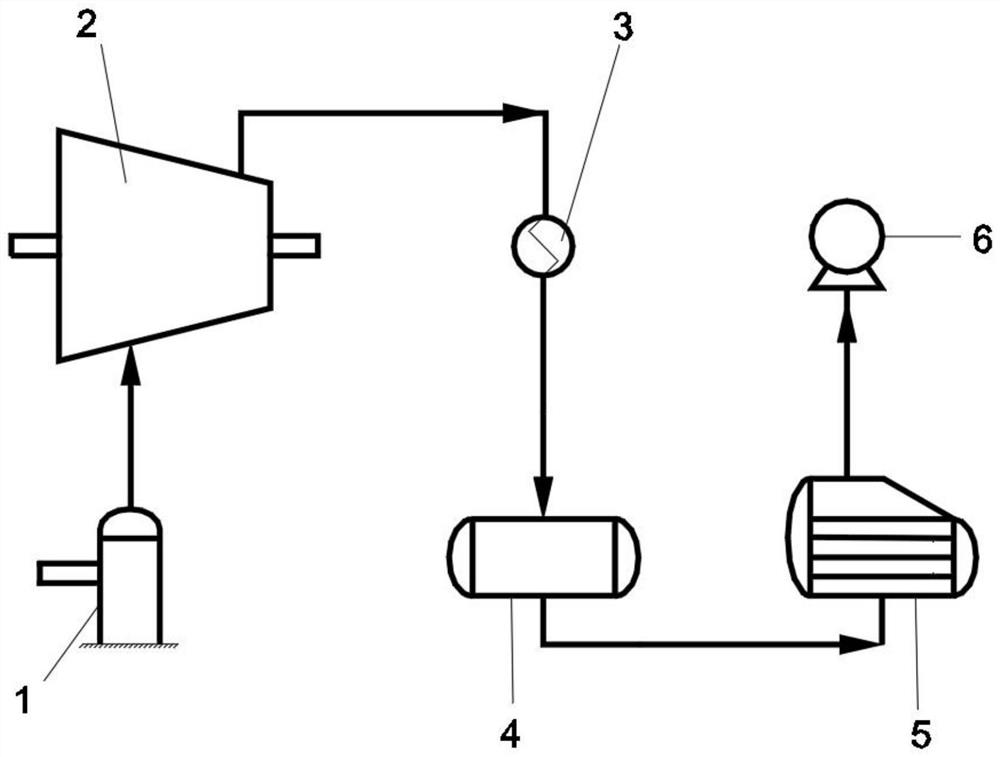

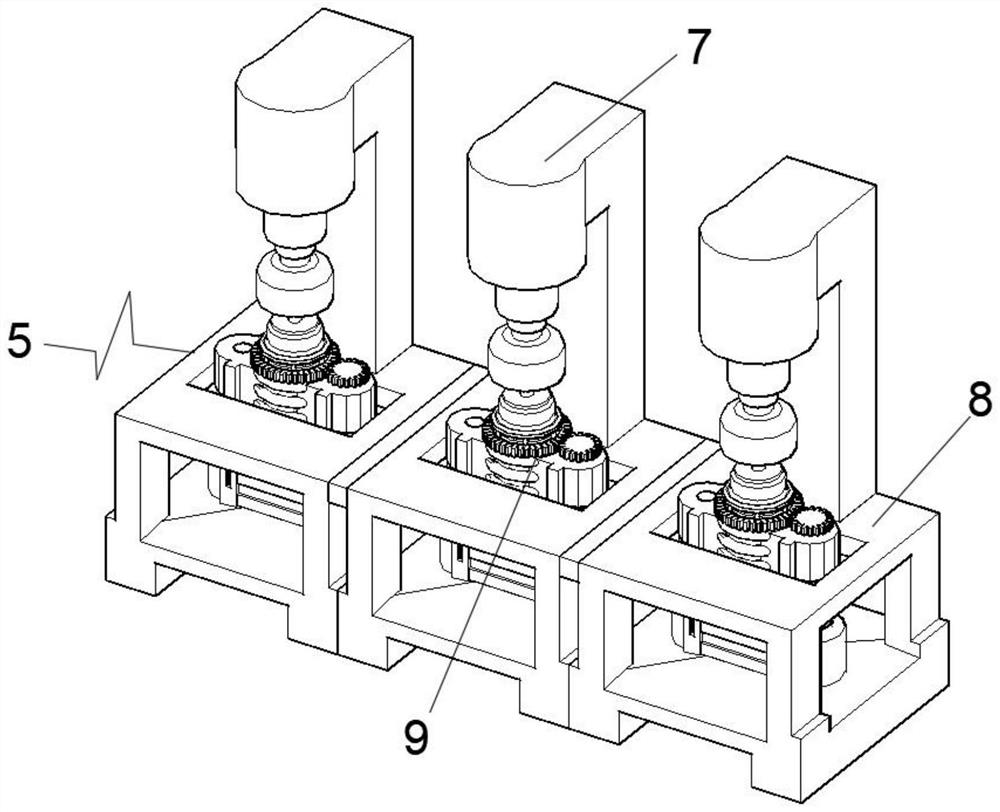

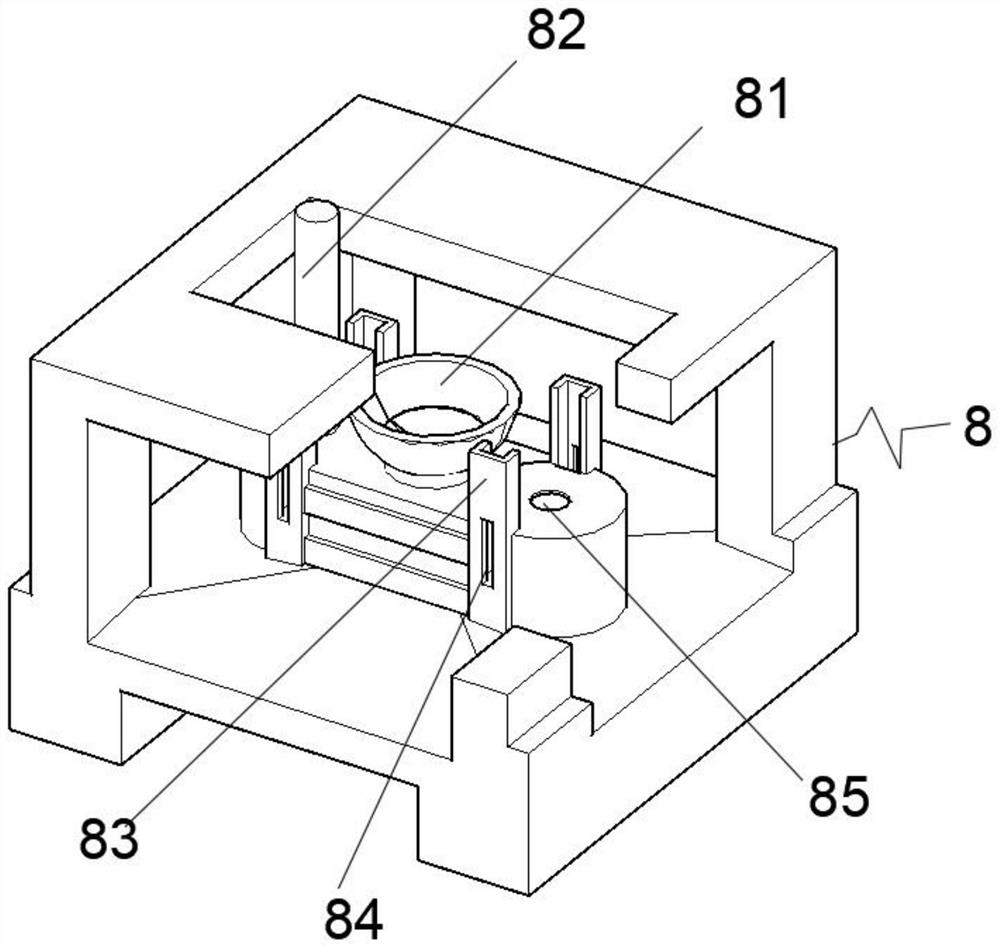

[0034] see Figure 1-7 , an embodiment provided by the present invention: an automatic welding production line of a pump casing press assembly robot, including a pump casing processing production line 1, a pump casing press assembly production line 2, a motor line installation production line 3, a rolling processing production line 4, a horizontal pump The press-fit welding production line 5 and the spring production line 6 are characterized in that: the pump casing press-fit production line 2 is fixedly connected to one end of the pump casing processing production line 1, and the motor line installation production line 3 is fixedly connected to one end of the pump casing press-fit production line 2 , the rolling processing production line 4 is fixedly connected to one end of the motor line installation production line 3, the horizontal pump press-fitting welding production line 5 is fixedly connected to one end of the rolling processing production line 4, and the spring produc...

Embodiment 2

[0046] On the basis of Example 1, such as Figure 8 As shown, the two sides of the processing table 8 are symmetrically connected with side plates 86 for rotation, the bottom surface of the side plates 86 is rotatably connected with support rods 87 , and the outer surface of the bottom edge of the support rods 87 is spirally connected with set screws 88 .

[0047] When this embodiment is implemented, by being able to expand the area on both sides of the processing table 8, more work space is provided for the staff, and it is convenient for the staff to place tools and objects to be processed. During maintenance, a working platform can be provided, so that the staff can quickly maintain the press-fitting tool 9 .

[0048] Working principle: Before the pump cover 91 and the pump casing 92 are press-fitted and welded to each other, after many processes, the bottom end of the pump casing 92 is inserted into the insertion groove 944, and then the bottom end of the pump cover 91 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com