Stacked spiral sludge dewatering machine and dewatering method thereof

A sludge dewatering machine and screw stacking technology, which is applied in water/sludge/sewage treatment, sludge treatment, chemical instruments and methods, etc. Problems such as clogged mud hopper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

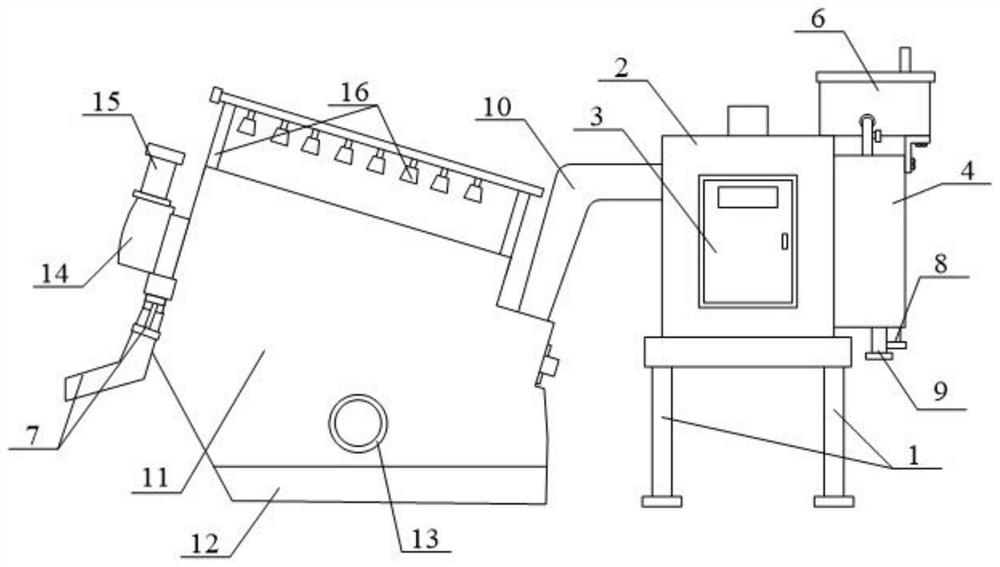

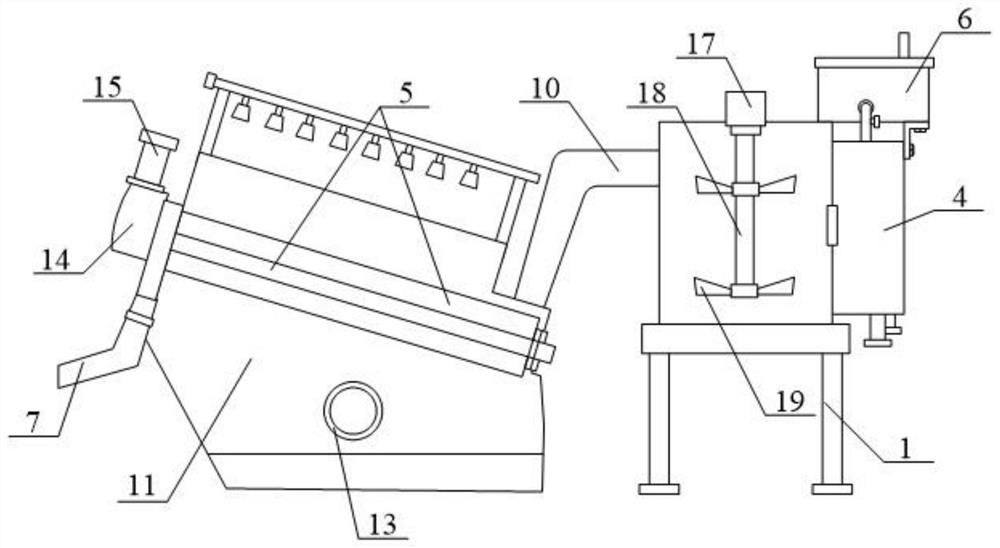

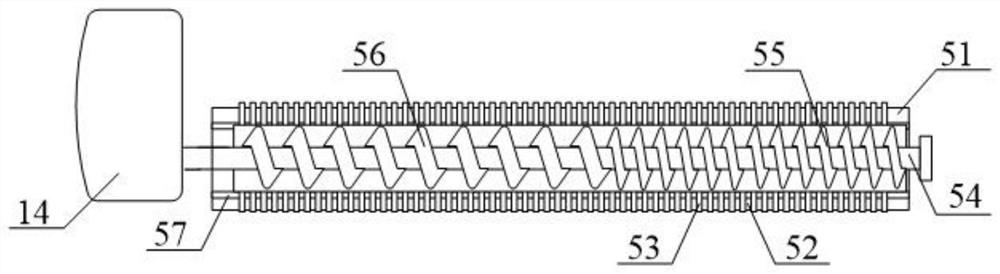

[0046] as attached figure 1 to attach figure 2 As shown, the present invention provides a stacked screw sludge dehydrator, including a support frame 1, a flocculation box 2, an electrical control cabinet 3, a buffer connection box 4, a stacked screw assembly 5, a drug-dosing buffer box assembly 6, and an anti- Block the mud hopper assembly 7, communicate with the delivery pipe 10, the processing box 11, the support base 12, the drain connection pipe 13, the reducer 14, the main shaft motor 15, the spray pipe 16 and the stirring motor 17,

[0047] The flocculation box 2 is bolted to the upper part of the support frame 1; the electrical control cabinet 3 is bolted to the front upper side of the flocculation box 2; the buffer connection box 4 is bolted to the flocculation box The upper right side of 2 is connected to the upper side of the interior; the lower part of the buffer connection box 4 is respectively bolted with a sewage overflow connection pipe 8 and a sewage inlet co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com