Continuous production integrated equipment for carbonizing straws to prepare fertilizer

A straw carbonization, integrated technology, applied in cutting equipment, biofuels, chemical instruments and methods, etc., can solve the problems of straw loss, affecting carbonization effect, and high pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

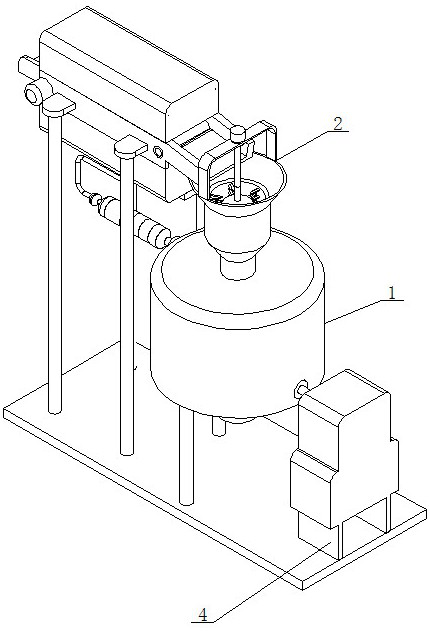

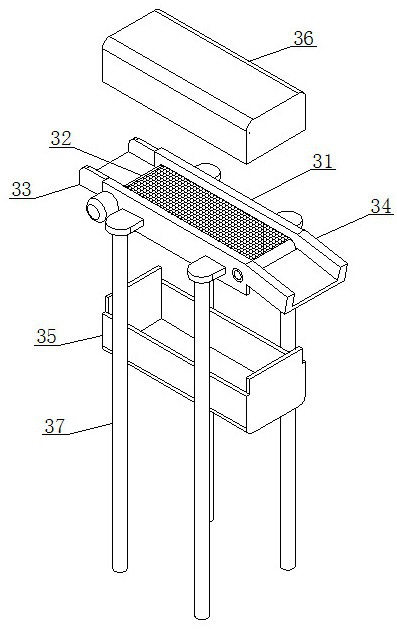

[0047] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 As shown, an integrated equipment for the continuous production of straw carbonization and fertilizer production includes a carbonization furnace body 1. The carbonization furnace body 1 includes a furnace body 11. A feed end 12 is connected to the top surface of the furnace body 11. The bottom of the furnace body 11 is communicated with an air inlet port 13, and the top of the end surface of the furnace body 11 is connected with an air outlet port 14, and the gas outlet end 14 of the furnace body 11 is communicated with a screw sleeve 53, and the furnace body 11 bottom end surface is communicated with a gas outlet port 14. There is a feeding end 15, and also includes:

[0048] The crushing assembly 2, the crushing assembly 2 is vertically connected and installed on the feed end 12 of the furnace body 11, the crushing assembly 2 is used to crush straw raw materials; the crushing ...

Embodiment 2

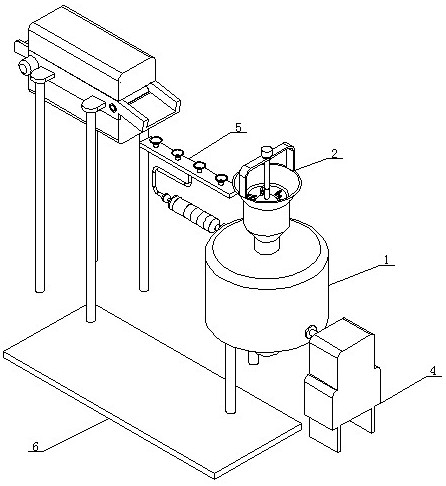

[0055] see Figure 8 and Figure 9 As shown, an integrated equipment for the continuous production of straw carbonization and fertilizer production includes a carbonization furnace body 1. The carbonization furnace body 1 includes a furnace body 11. A feed end 12 is connected to the top surface of the furnace body 11. The bottom of the furnace body 11 is communicated with an air inlet port 13, and the top of the end surface of the furnace body 11 is connected with an air outlet port 14, and the gas outlet end 14 of the furnace body 11 is communicated with a screw sleeve 53, and the furnace body 11 bottom end surface is communicated with a gas outlet port 14. There is a feeding end 15, and also includes:

[0056] The crushing assembly 2, the crushing assembly 2 is vertically connected and installed on the feed end 12 of the furnace body 11, the crushing assembly 2 is used to crush straw raw materials; the crushing barrel 21 is vertically arranged directly above the feed end 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com