Heading machine and main driving shaft end seal capable of monitoring temperature in real time

A main drive shaft, real-time monitoring technology, applied to the sealing of the engine, thermometer parts, thermometers, etc., can solve the problems of space confinement, wear and tear, and lack of high-reliability in-situ temperature measurement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

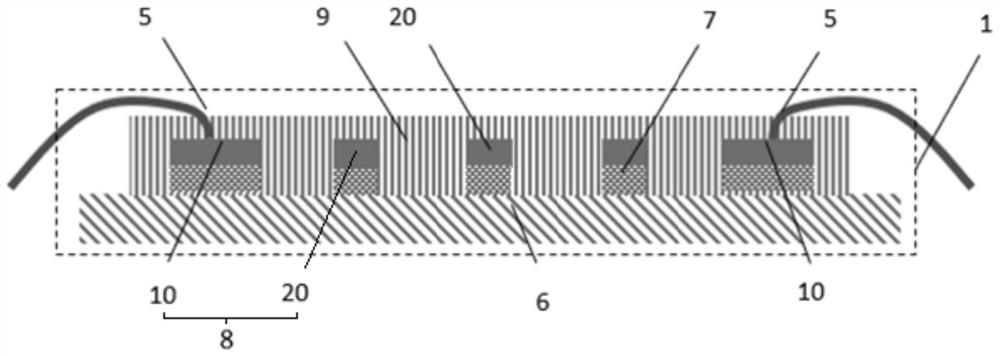

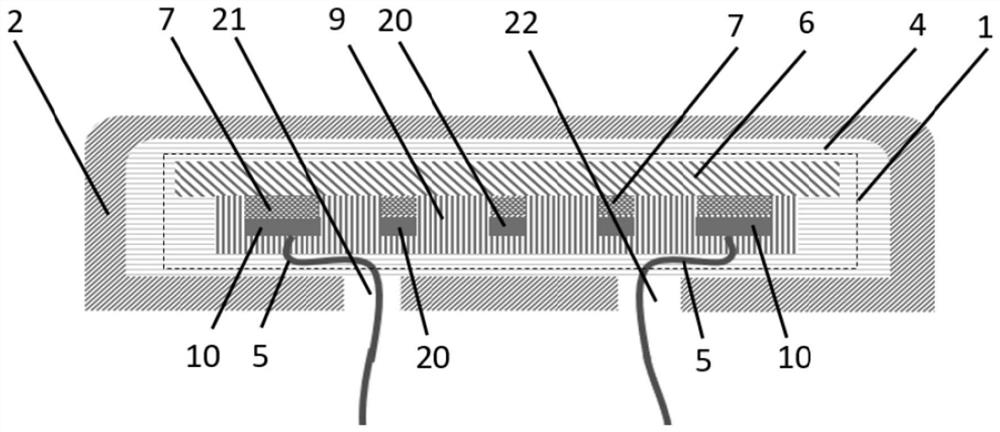

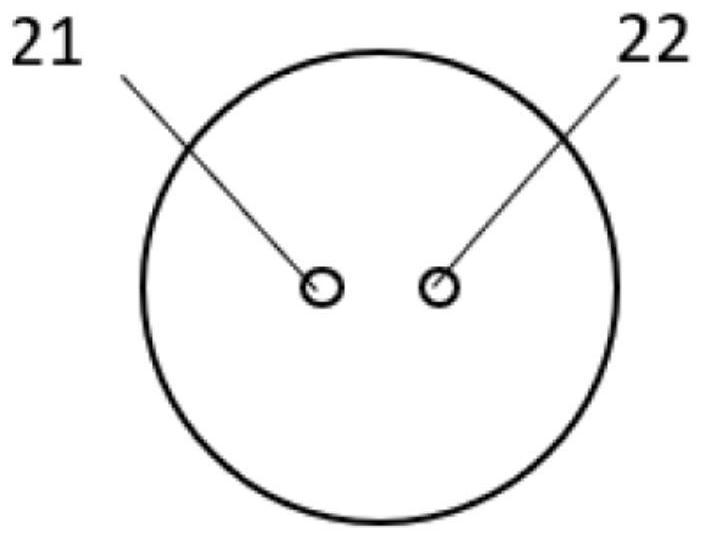

[0042] refer to Figure 1 to Figure 3 The resistor chip 1 designed in the present invention includes a base layer 6, an adhesive layer 7, a sensitive layer 8 and a passivation layer 9, wherein the sensitive layer 8 includes a resistor strip 20 and a resistor strip pad 10, and the material of the passivation layer 9 can be aluminum oxide Or glass these insulating, corrosion-resistant materials. Both ends of the resistance strip 20 have resistance strip pads 10, and each resistance strip pad 10 is connected with a signal lead 5, one end of the signal lead 5 is connected to the resistance strip pad 10, and the other end passes through the package shell 2 of the sensor. The first through hole 21 and the second through hole 22 at the bottom are externally connected with a signal processing circuit. The resistor chip 1 is placed upside down horizontally inside the packaging shell 2 ( figure 1 The orientation shown is the situation where the resistor chip 1 is placed upright. fig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Line width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com