Scraper conveyor fault diagnosis system and method

A fault diagnosis system and technology of scraper conveyor, which is applied in the testing of mechanical components, testing of machine/structural components, instruments, etc., can solve problems such as loss, harsh working environment of scraper conveyor, and variable workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The vibration signal sensor used in traditional scraper conveyor fault diagnosis is in direct contact with the scraper conveyor, which has poor adjustability, and the working environment of the scraper conveyor is harsh. On the one hand, it is easy to damage the sensor structure; Serious interference will be caused to the signal, which will eventually make it difficult to obtain accurate and effective diagnostic information. In view of the above problems, this embodiment designs a scraper conveyor fault diagnosis system.

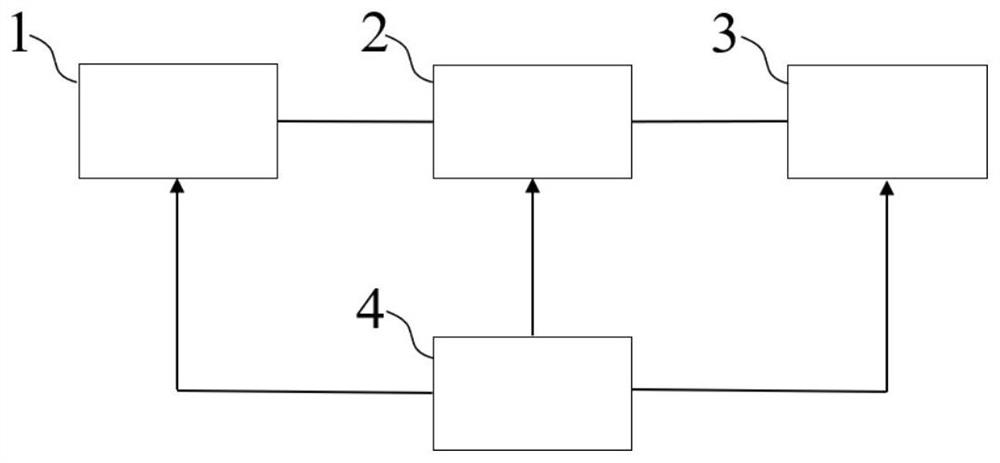

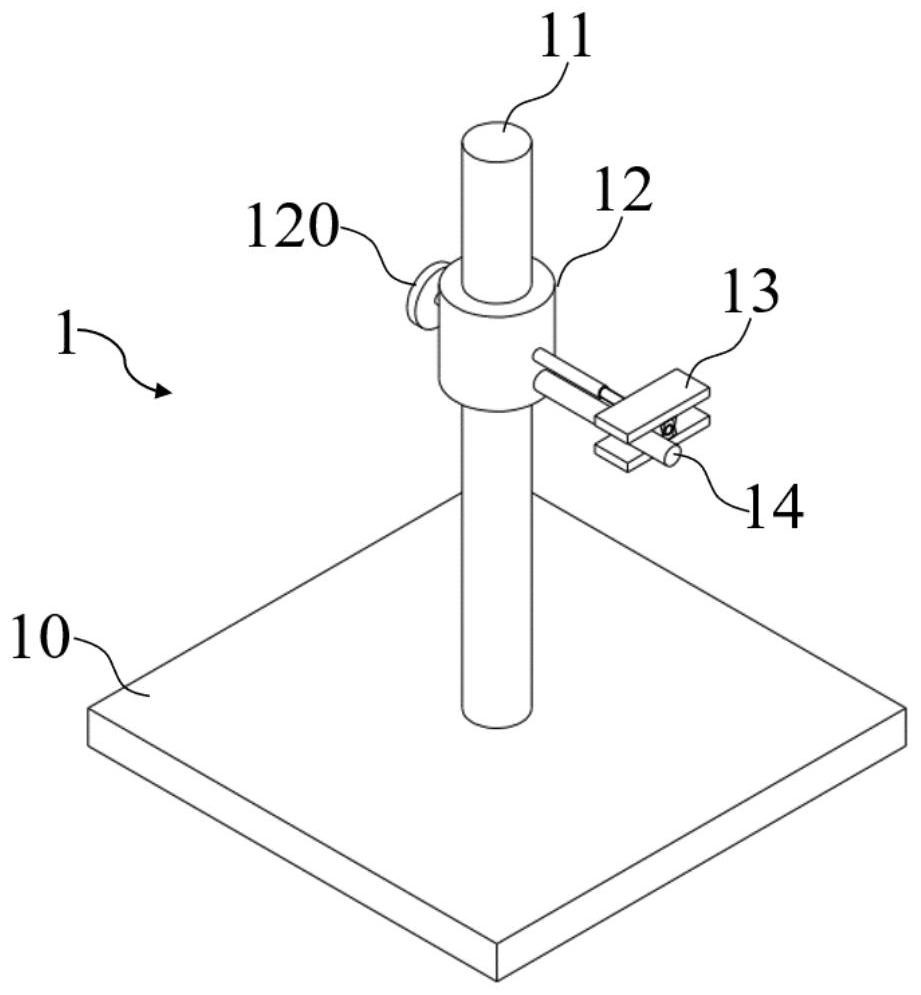

[0059] Such as figure 1 As shown, the scraper conveyor fault diagnosis system of this embodiment is composed of an acoustic signal acquisition module 1, a processing terminal 2, an interactive module 3 and a power supply 4, wherein the acoustic signal acquisition module 1 includes an acquisition terminal, a signal conditioning unit and a lower computer, The three are sequentially connected by signal. The acquisition end is arranged beside the shaft en...

Embodiment 2

[0064] This embodiment provides a method for fault diagnosis of a scraper conveyor, the method flow chart is as follows Figure 4 As shown, the scraper conveyor fault diagnosis system based on Embodiment 1 aims to solve the problem that interference factors affect the accuracy of diagnosis results when diagnosing sound signals. The steps are as follows:

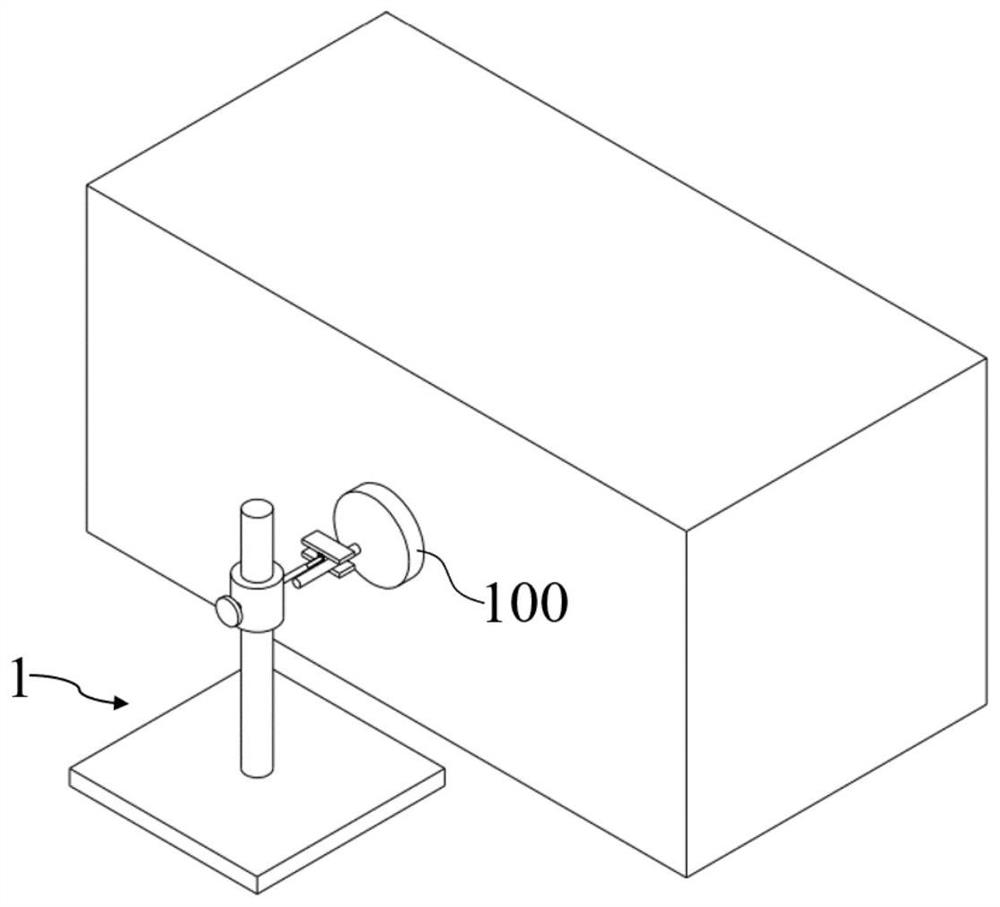

[0065] S1. Arrange the acquisition end of the acoustic signal acquisition module 1 on the side of the shaft end 100. The acquisition end of this embodiment is provided with a microphone 14, which is arranged towards the center of the shaft end 100. The microphone 14 collects the sound emitted by the shaft end 100 when the reducer is started. After the sound signal is amplified by the signal conditioning unit, the lower computer transmits the collected sound signal as the original sound signal to the processing terminal 2;

[0066] S2. The processing terminal 2 processes the original sound signal, and first decomposes the orig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com