Method for simulating karst caves in different filling states and physical simulation test system

A technology of physical simulation and test system, which is applied in the field of physical simulation test system for simulating caves in different filling states, and can solve problems such as inconsistency of stress state, inability to withstand pressure, and inconsistency of stress state of karst caves, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

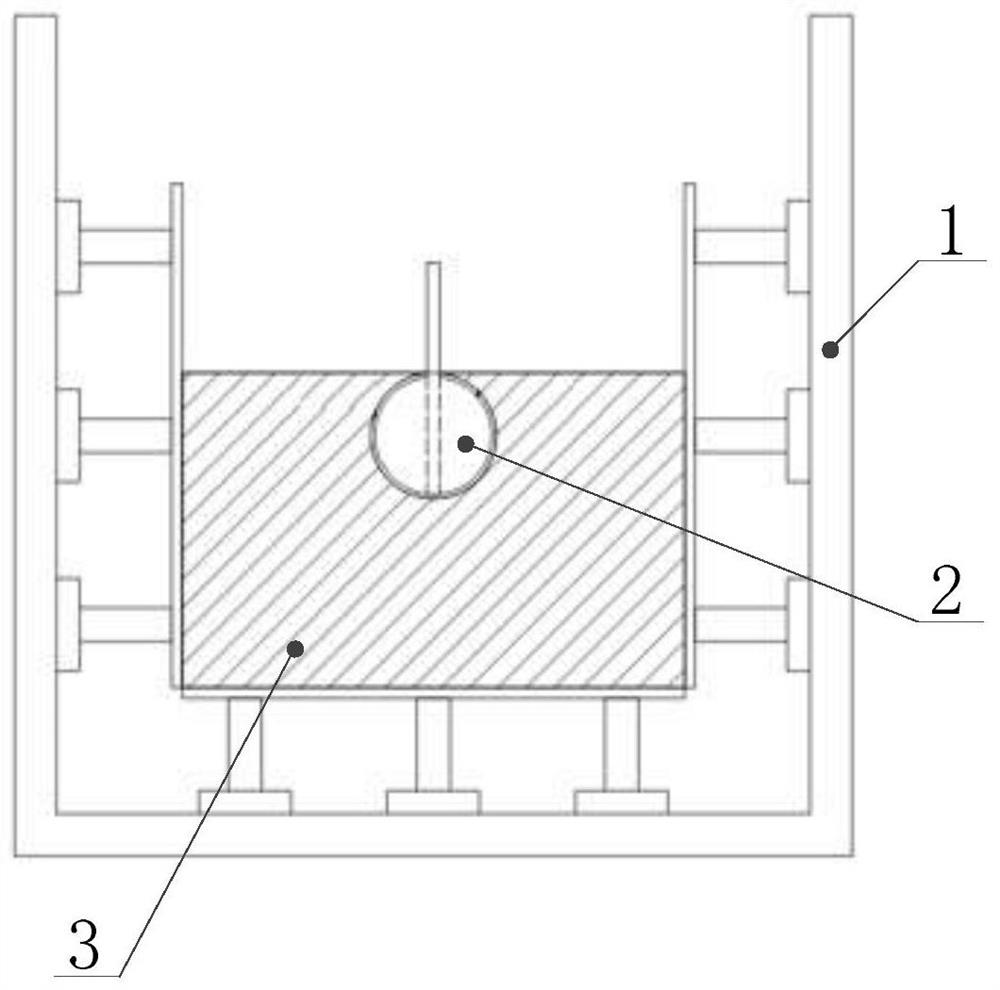

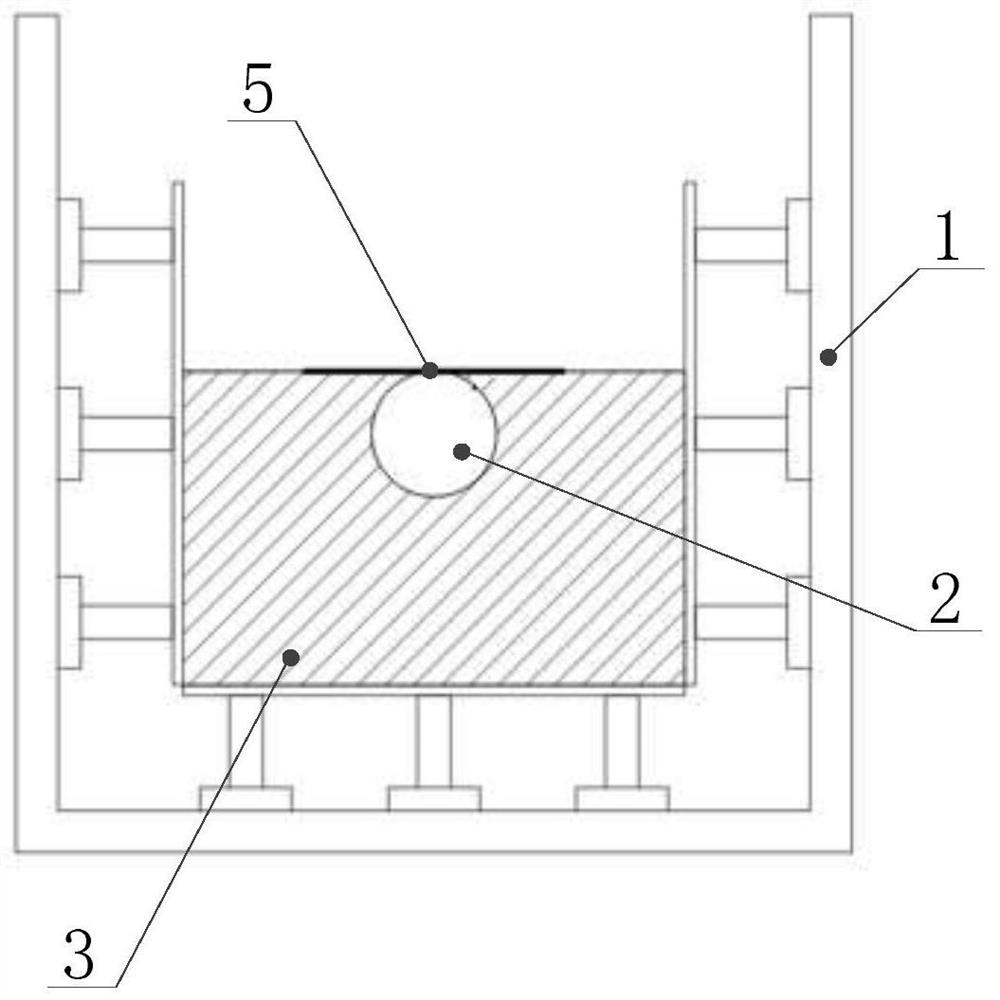

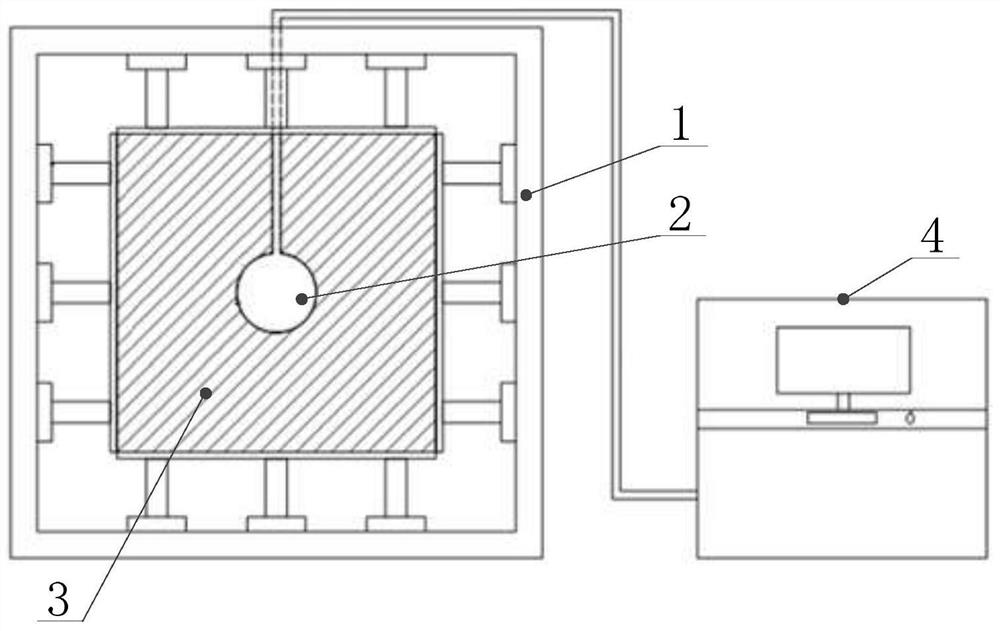

[0036] The present invention will be further described below in conjunction with accompanying drawing.

[0037] The problems existing in the prior art are summarized as follows: the existing simulation method for filling reservoir caves simply considers the filling medium and ignores the influence of the surrounding rocks around the cave, and the simulated cave does not match the stress state of the actual cave; The cavitation technology of reservoir caves can only be used to study the plane strain problem, and cannot be used for the cavitation of buried caverns; the existing other simulation methods for filling reservoir caves can only simulate simple water displacement phenomena, and the simulation The system cannot withstand pressure and cannot adapt to the simulation requirements of different filling states; other existing simulation methods for filling reservoir caves artificially create through-cracks on the simulation body, which has a great influence on the test results. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com