3D printing pipeline compensation design method based on residual stress correction

A residual stress, 3D printing technology, used in 3D modeling, design optimization/simulation, calculation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to more clearly illustrate the technical solutions in the embodiments or the prior art embodiment of the present invention, the following embodiments or drawings described in the prior art needed to be used to make a simple embodiment will be introduced hereinafter, the following description of the drawings Some embodiments of the present invention are embodiments, those of ordinary skill in the art is concerned, without creative efforts, can derive from these drawings other drawings.

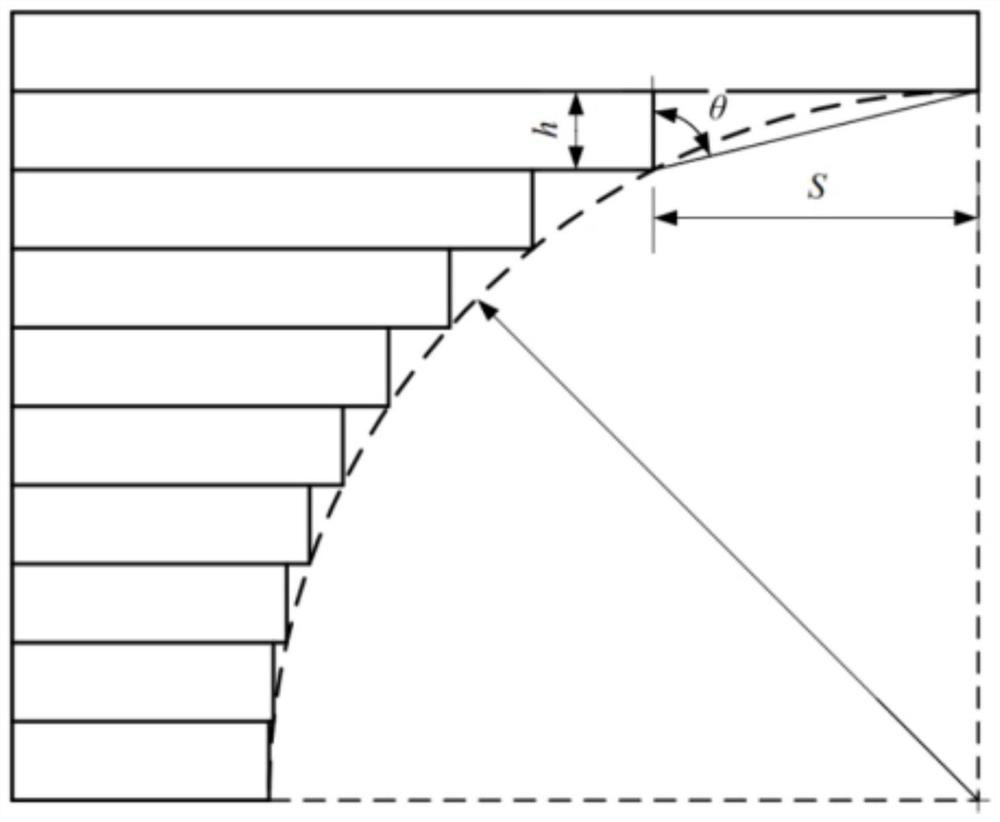

[0038] The present invention is one kind of the proposed 3D printing pipe compensator design method based on the correction residual stress, comprises the steps of:

[0039] Step S1, the determined diameter, wall thickness, length of the pipe and other design parameters of the pipe to be printed, rendering three-dimensional graphics software for the .STL file and saved SLM printers recognizable;

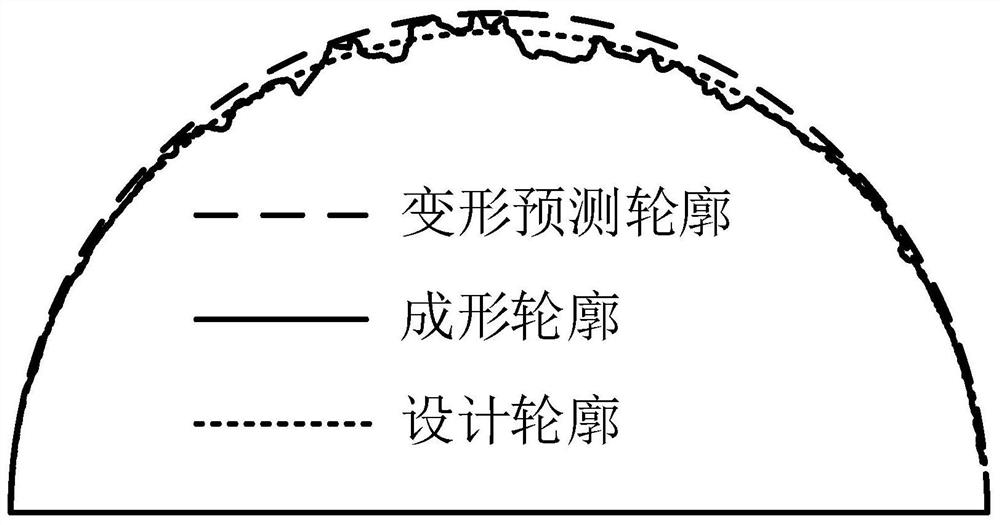

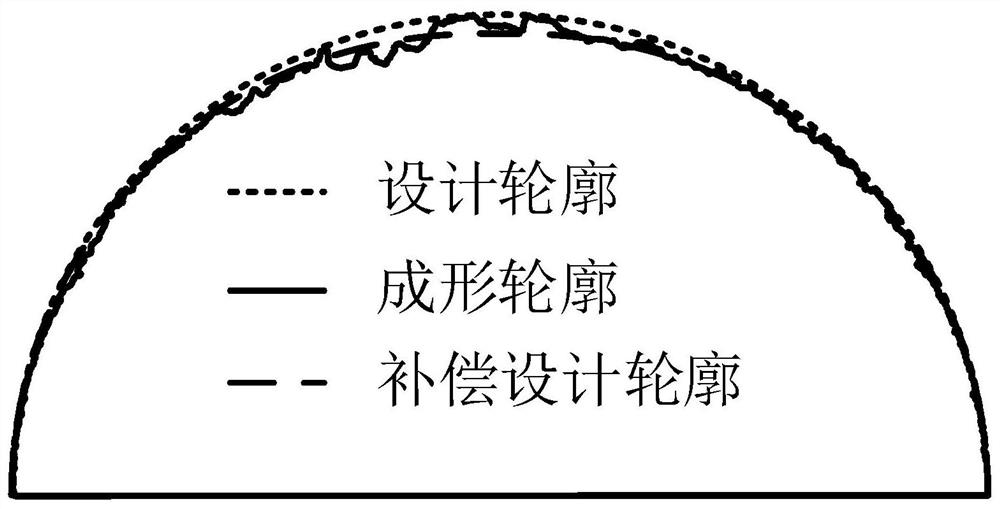

[0040] Step S2, the present example is a pipe radius of 5mm study, the upper half of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com