Production line efficiency automatic monitoring and analysis system and method

A technology for production line efficiency and automatic monitoring, applied in office automation, manufacturing computing systems, data processing applications, etc., it can solve the problems that calculations remain on the surface, no further subdivision, and low efficiency, saving labor input costs and accurate descriptions Improve performance and ensure reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The invention provides an automatic monitoring and analysis system and method for large-scale production line equipment, and the specific scheme is as follows.

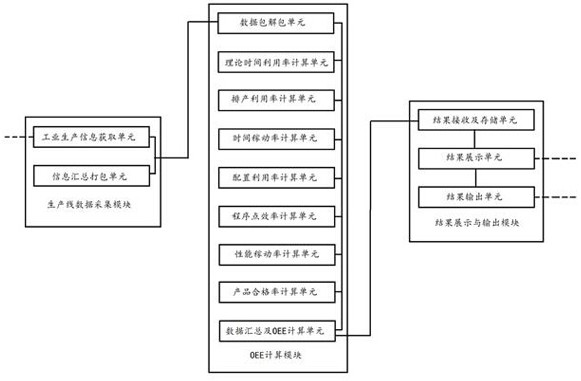

[0069] Such as figure 1 As shown, an automatic monitoring and analysis system for production line efficiency includes:

[0070] The production line data acquisition module is used to obtain the industrial production information of the production line in the industrial production enterprise, package and generate industrial production data packages and upload them; the industrial production information mentioned here includes at least the number of working days, PPC (Production Planning and Control, production planning and Control) system scheduling time, actual production scheduling time, production line running time, production line equipment configuration CPH (Components Per Hour, assembly components per hour), module configuration CPH, PPC system theoretical production points, actual production points, produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com