Screening device with dust removal function for rice production

A screening device, rice technology, applied in the direction of screening, separating solids from solids with airflow, solid separation, etc., can solve problems such as inability to meet multi-stage screening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

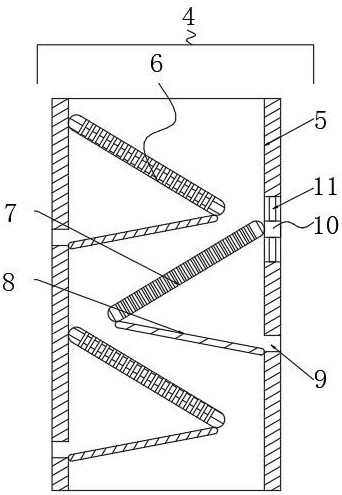

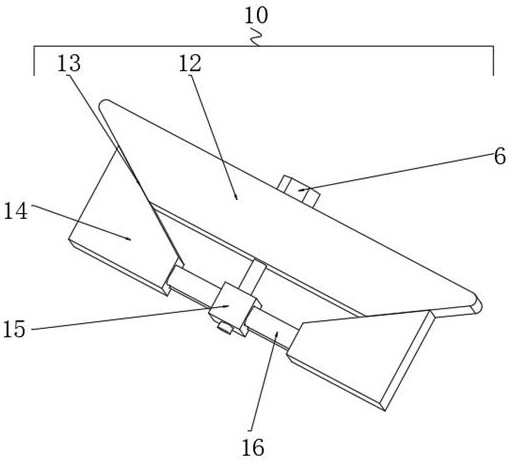

[0036] A screening device for rice production with dust removal function, such as figure 1 , 2 As shown, including a base 1, the top outer wall of the base 1 is sequentially provided with a throwing type feeding mechanism 2, an impurity removal mechanism 3 and a screening mechanism 4 according to the rice path, and the screening mechanism 4 includes a screening housing 5 and opposite and The sieve assembly 6 arranged in a staggered manner inside the screening housing 5, the sieve assembly 6 includes a screen 7 and a screen 7, the screen 7 is rotatably connected to the outer wall of the opposite side of the debris guide 8, and the debris guide 8 The outer wall on the other side is fixedly connected to the inner wall of the screening housing 5 , the outer wall on the other side of the screen 7 is rotatably connected to a slider assembly 10 , and the slider assembly 10 is slidably connected to the screening housing 5 .

[0037] In order to solve the leakage problem; such as fi...

Embodiment 2

[0041] A screening device for rice production with dust removal function, such as Figure 6 , 7 As shown, in order to solve the dust removal problem; this embodiment makes the following improvements on the basis of Embodiment 1: the impurity removal mechanism 3 includes a dust removal housing 27 and a fan 29, and one side of the outer wall of the dust removal housing 27 is fixed by bolts There is an air inlet guide shell 28 communicating with its inner cavity, the fan 29 is fixed on the other side of the air intake guide shell 28 by bolts, and the other side outer wall of the dust removal housing 27 is provided with a linear array of imitation filter Component 30.

[0042] In order to solve the wind speed of dust removal and simplify the structure to reduce costs, such as Figure 7 As shown, the imitation filter assembly 30 includes a baffle 31 and a sundry discharge port 2 33 opened on the inner wall of the dust removal housing 27, and the top outer wall of the baffle 31 is...

Embodiment 3

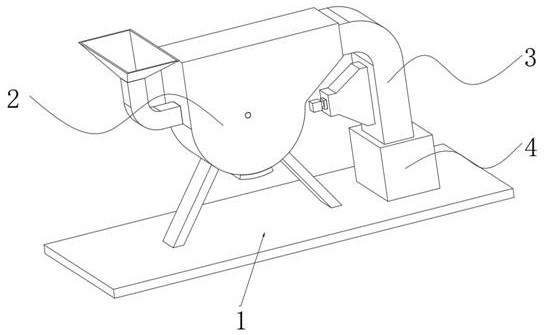

[0046] A screening device for rice production with dust removal function, such as Figure 4 As shown, in order to solve the dust removal problem; this embodiment makes the following improvements on the basis of embodiment 2: the throwing type feeding mechanism 2 includes a feeding housing 17 fixed on the top of the base 1 through legs 21 and movably connected to The roller assembly 20 inside the material delivery housing 17, the peripheral outer wall of the roller assembly 20 is fixed with a uniform material delivery plate 18 by bolts, and one side of the material delivery housing 17 is welded with a feed material communicating with its inner cavity. Bucket 19, the inner wall of the roller assembly 20 is fixedly connected with a main shaft 25, and the outer wall of the main shaft 25 is connected with a drive motor 26 through a coupling, and the drive motor 26 is fixed on the outer wall of the material delivery housing 17 by bolts.

[0047] In order to reduce dead weight and sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com