Reinforcing rib structure for preventing channel cooling flat pipe from deforming, and flat pipe reinforcing method

A rib and ring-shaped structure technology, applied in metal processing equipment, glass manufacturing equipment, glass furnace equipment, etc., can solve the problem of easy collapse and deformation of the top of the flat tube

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

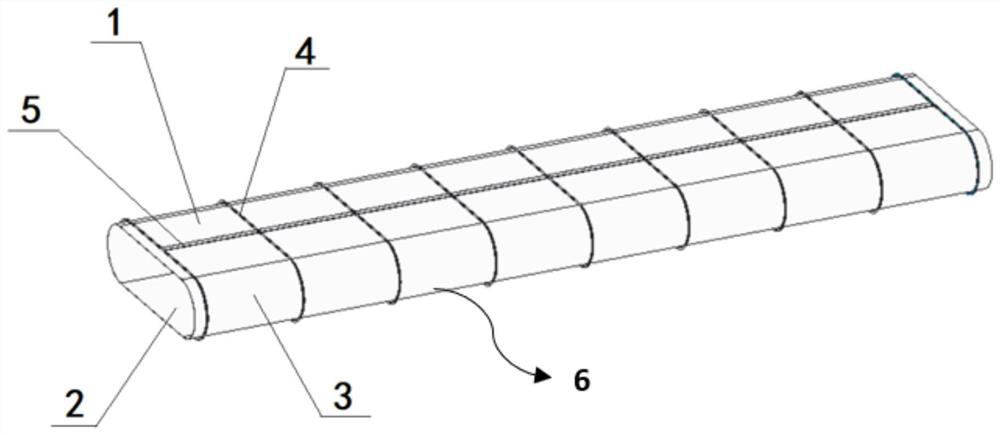

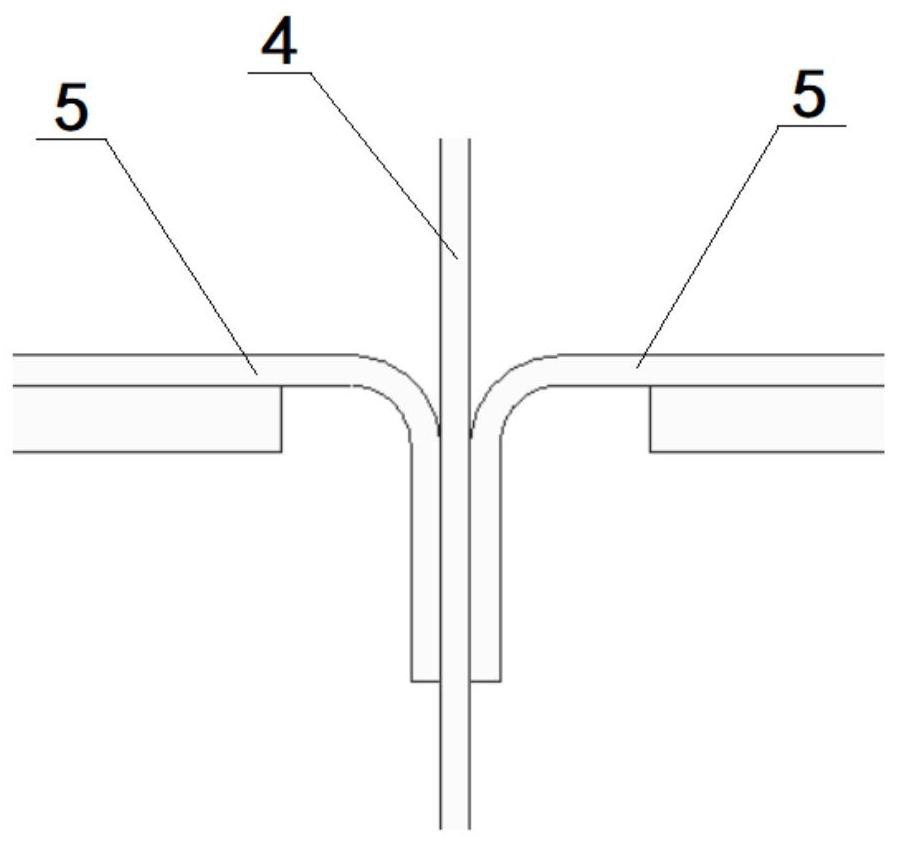

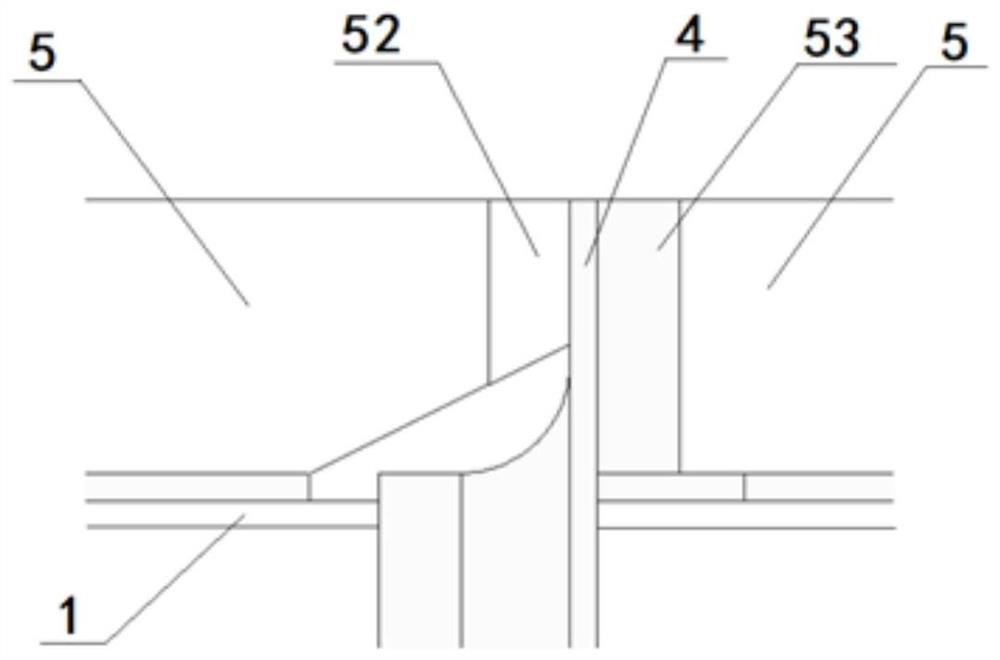

[0032] Such as figure 1 As shown, the present invention provides a rib structure to prevent the deformation of the channel cooling flat tube, which belongs to the TFT-LCD substrate glass industry. By designing a special rib structure, the radial section and axial straightness of the channel cooling flat tube can be improved. To strengthen the stabilizing effect, prevent the collapse and deformation of the large cross-section flat tube structure during the manufacturing process and heating production process, protect the structural integrity of the platinum channel body and prevent the damage of the attached top thermocouple.

[0033] Specifically, the upper surface 1 of the cooling flat tube, the corresponding lower surface 2 of the cooling flat tube, and the side arc surface 3 of the cooling flat tube constitute the cooling flat tube 6, the tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com