Standard rubber for checking sulfur analyzer and preparation method of standard rubber

A technology of standard rubber and sulfur change meter, applied in the field of compound rubber tester calibration, can solve the problems of inaccurate data and production of a large number of waste products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

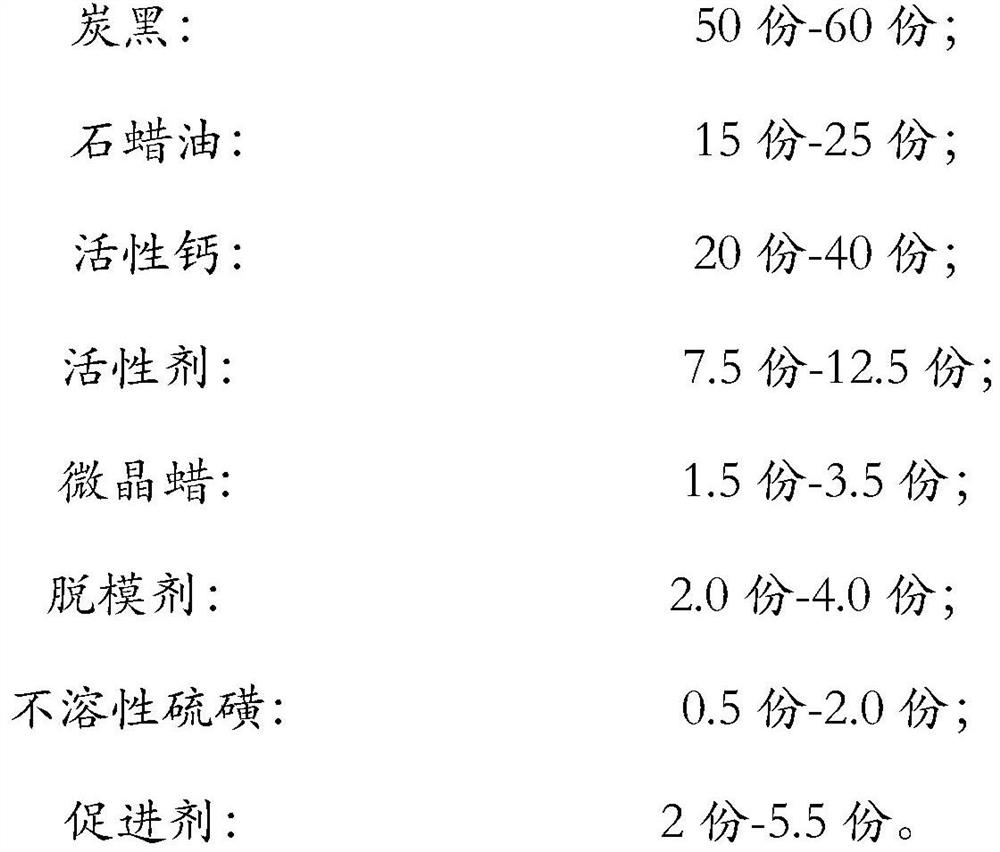

[0025] A kind of standard glue for calibrating rheometer, it comprises the component of following mass fraction: 100 parts of butyl rubber, 55 parts of carbon black, 15 parts of paraffin oil, 20 parts of active calcium, 1.5 parts of microcrystalline wax, 7.5 parts Active agent, 2.0 parts of release agent, 0.5 parts of insoluble sulfur, 5.5 parts of accelerator,

[0026] Among them, the butyl rubber adopts IIR1751 type (or IIR1675 type), and the main rubber adopts butyl rubber with good stability to the external environment as the main material, which is suitable for high-temperature mixing, and the filling factor is about 5-10% more than conventional rubber materials. In this way, the rubber compound produced by mixing has good dispersion, uniform performance and good stability;

[0027] Carbon black adopts N550 model, which is used as a reinforcing agent to improve the tensile strength of the rubber and adjust the hardness of the rubber; paraffin oil is used as a plasticizer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com