Energy-saving full-automatic multifunctional arranged biogas digester and working method thereof

A multifunctional biogas digester technology, applied in biochemical equipment and methods, biochemical cleaning devices, enzymatic/microbiological devices, etc., can solve the problems of low gas production and low utilization rate of biogas digesters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the above features and advantages of the present invention, it can be more easily understood, and the following examples are forth, and the accompanying drawings are described in detail, but the present invention is not limited thereto.

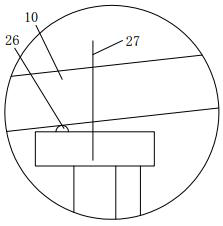

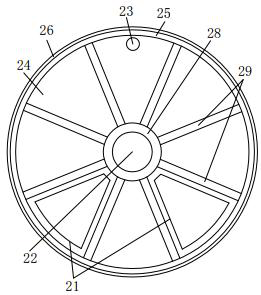

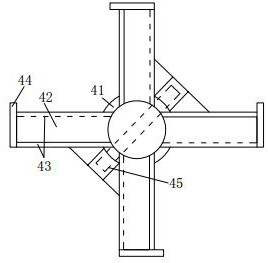

[0033] refer to Figure 1 to 5

[0034]Setting an energy-saving automatic multi digester, comprising the body 10 lying on the ground, the tank body 20 via a spacer plate between the plurality of partition 11 fermentation to fermentation slurry stepwise. Tank body disposed along the axis direction of a rotating shaft 30 extends through the center of each partition plate, positioned between the central axis of rotation is provided for each of the fermentation are agitated to promote, and the residue embrace pressure slurry agitation impeller 40, the the left end of said body and connected to a pressure between the feed hopper 51 of the cell body 50, provided with a central rotation shaft to the drive mechanism of the automati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com