Coordination control method for coal-fired cogeneration unit under self-adaptive BTU

A combined heat and power unit, coordinated control technology, applied in the direction of combustion method, combustion control, fuel supply adjustment, etc., can solve the problems of high cost, complex control logic, and long time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

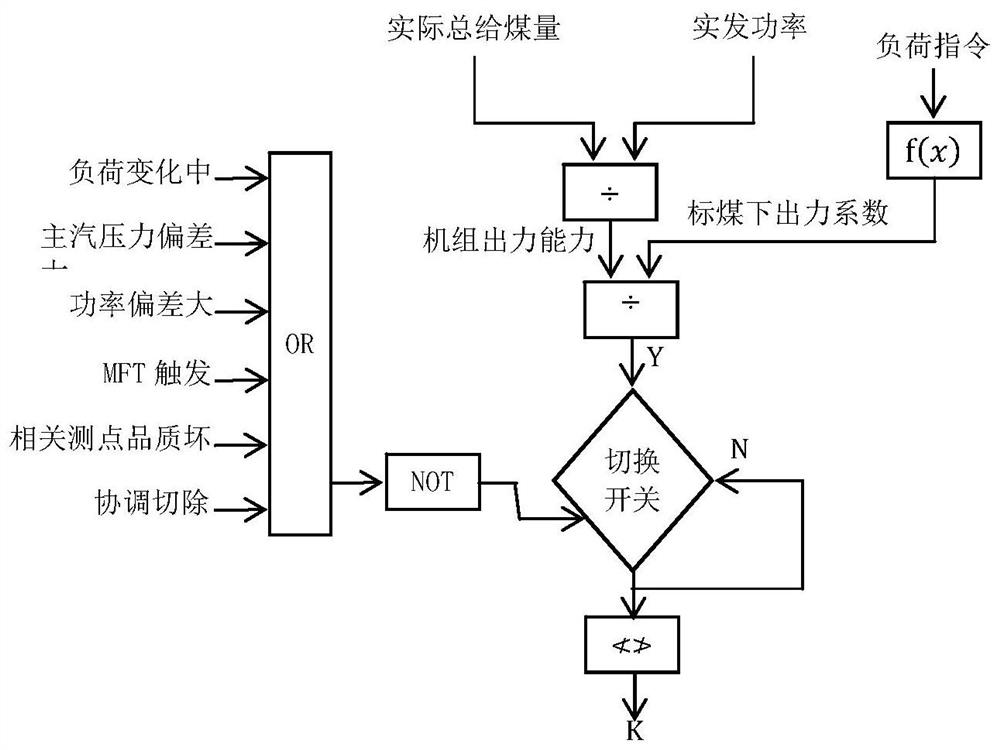

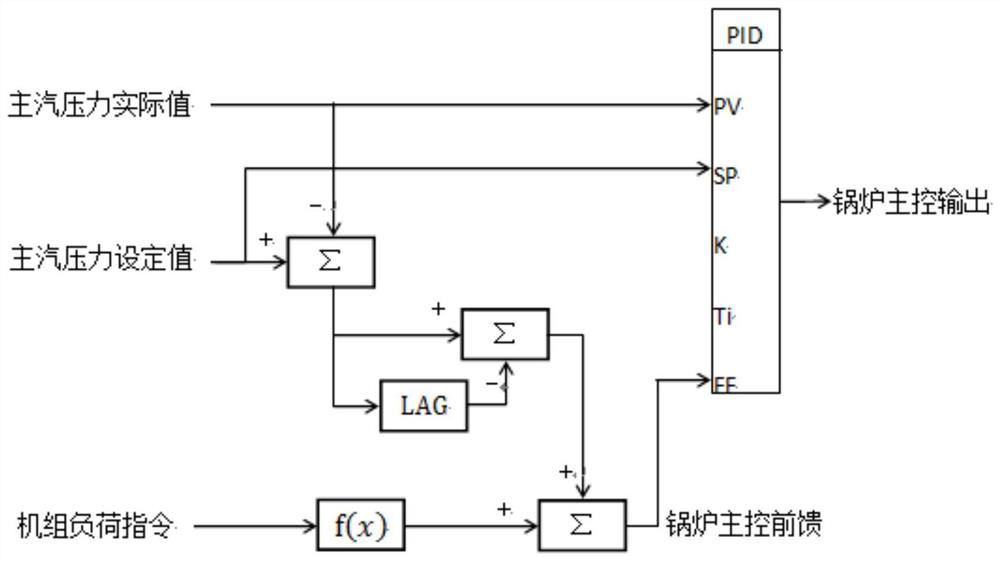

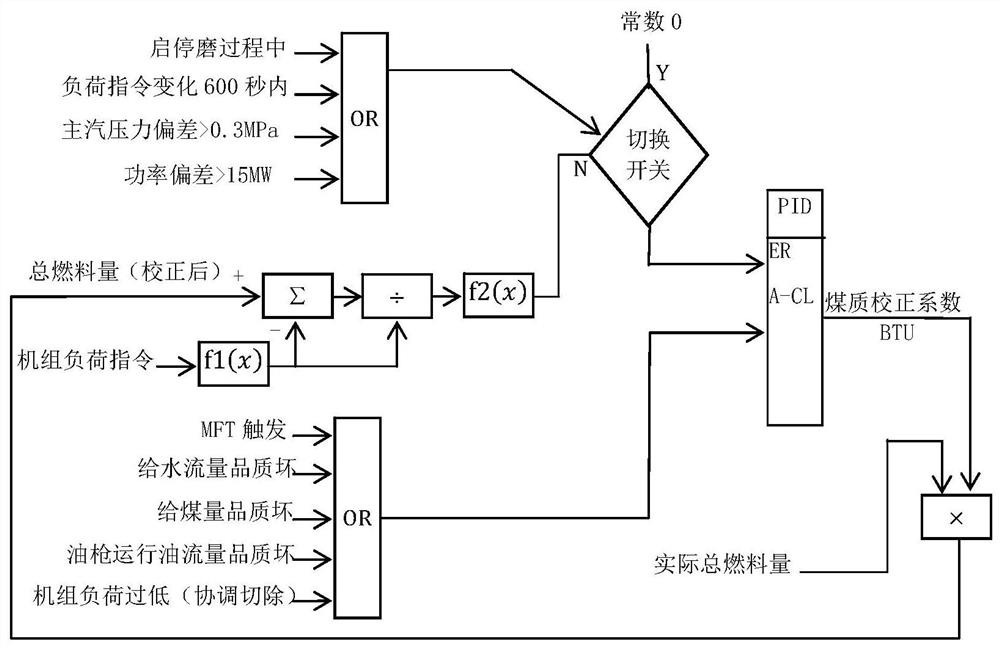

Method used

Image

Examples

Embodiment 1

[0059] Summary of this example, the power plant boiler is a 300MW (cogeneration) coal-fired generator set, model BLK-1025, subcritical parameters, direct-blown pulverization system, double combustion chamber, 100% fly ash reburning, direct-current liquid Slagging furnace, two medium-speed coal mills are designed on each side of the double combustion chamber. 16 swirl burners are arranged on the top of the combustion chamber, and one coal mill is matched with four burners in different positions. In order to ensure stable combustion, the burner is designed with the swirl adjustment of the central air duct and the secondary air duct. The actual application numerical example of the 300MW cogeneration unit is as follows:

[0060] 1. Coal quality correction coefficient output example

[0061] Set the standard coal combustion state, that is, under 4% oxygen content, the current load is 330MW, and the total coal supply is 36kg / s. When the coal quality changes, assuming that the coal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com