Refrigerant recovery method capable of effectively avoiding volatilization of thermoelectric refrigerant

A refrigerant recovery and refrigerant technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve problems such as environmental damage, incomplete recovery of gas-phase refrigerants, leakage, etc., to reduce pollution and facilitate secondary recycling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

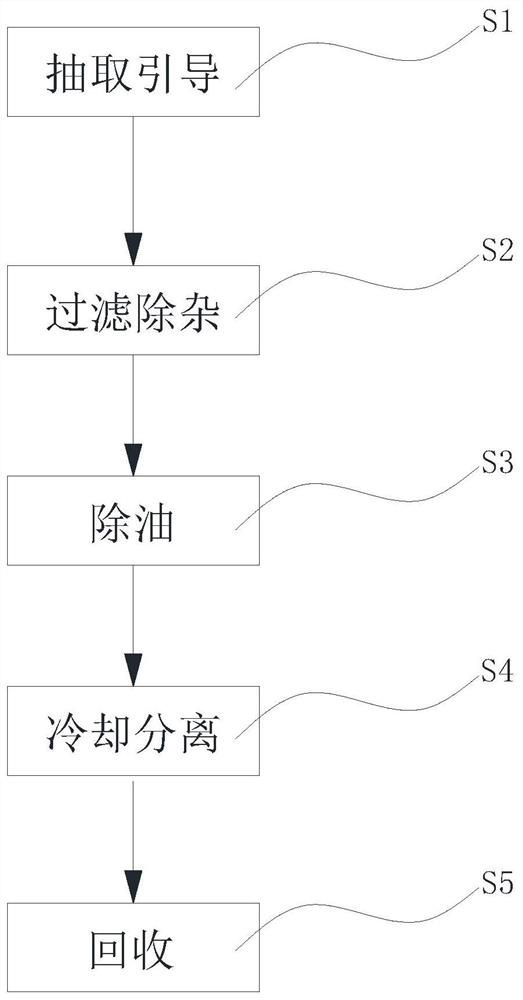

[0025] Please refer to figure 1 ,in, figure 1 It is a structural block diagram of a preferred embodiment of the refrigerant recovery method that can effectively avoid the volatilization of thermoelectric refrigerant provided by the present invention. A refrigerant recovery method that can effectively avoid volatilization of thermoelectric refrigerants includes the following steps:

[0026] S1. Extraction guide: extract and guide the used refrigerant gas-liquid mixture;

[0027] S2. Filtration and removal of impurities: filter and dry the impurities contained in the refrigerant to remove the moisture in the gas phase refrigerant, and the liquid phase refrigerant enters the interior of the refrigerant recovery bottle;

[0028] S3. Degreasing: Separating and collecting the refrigerated lubricating oil contained in the used refrigerant;

[0029] S4. Coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com