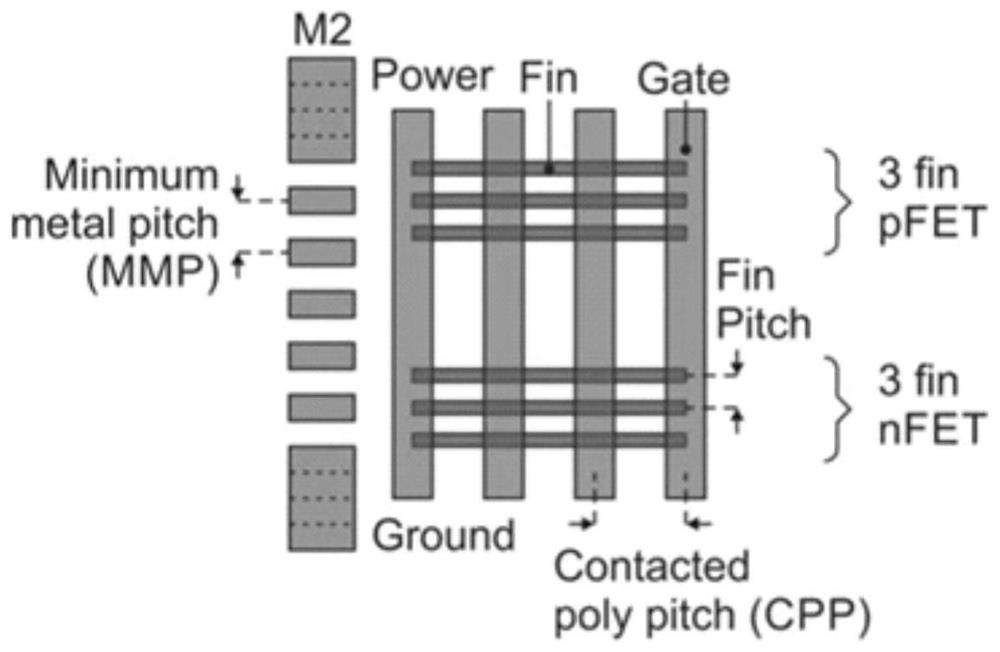

Method for manufacturing pre-cut SDB FinFET

A manufacturing method and a part of the technology, applied in the direction of semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as device performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The embodiments of the present invention will be easily understood by those skilled in the

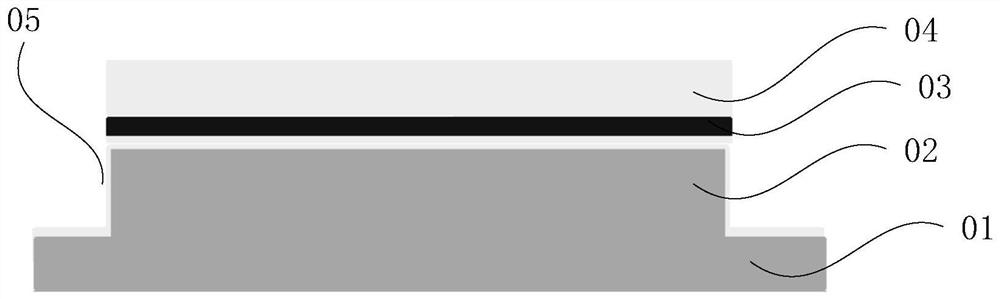

[0046] See Figures 2 to 16 . It should be noted that the illustrations provided in the present embodiment will illustrate the basic contemplation of the present invention in a schematic manner, and only the components, shapes, shapes, shapes, shapes related to the components of the present invention are displayed in the pattern rather than in accordance with the actual implementation. Dimensions, the type, quantity, and proportion of each component can be a random change in the actual implementation, and its component layout is also more complicated.

[0047] The present invention provides ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com