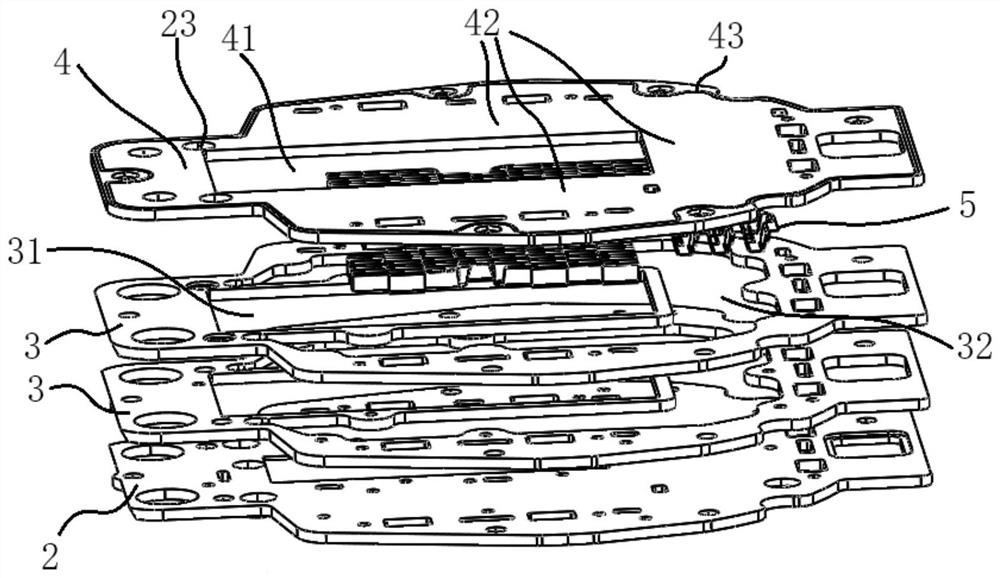

Multi-layer structure heat dissipation plate of BSG motor inverter and processing method

A BSG motor, multi-layer structure technology, applied in electrical equipment structural parts, electrical components, cooling/ventilation/heating renovation, etc., can solve the traditional air-cooled heat dissipation effect, harsh working environment, complex heat dissipation plate processing technology And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

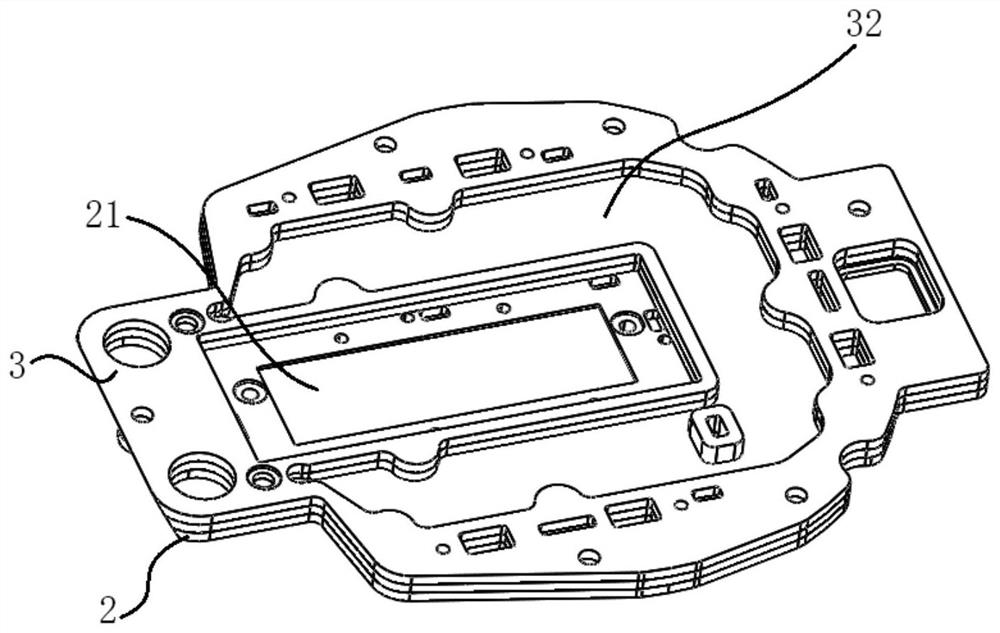

Embodiment 1

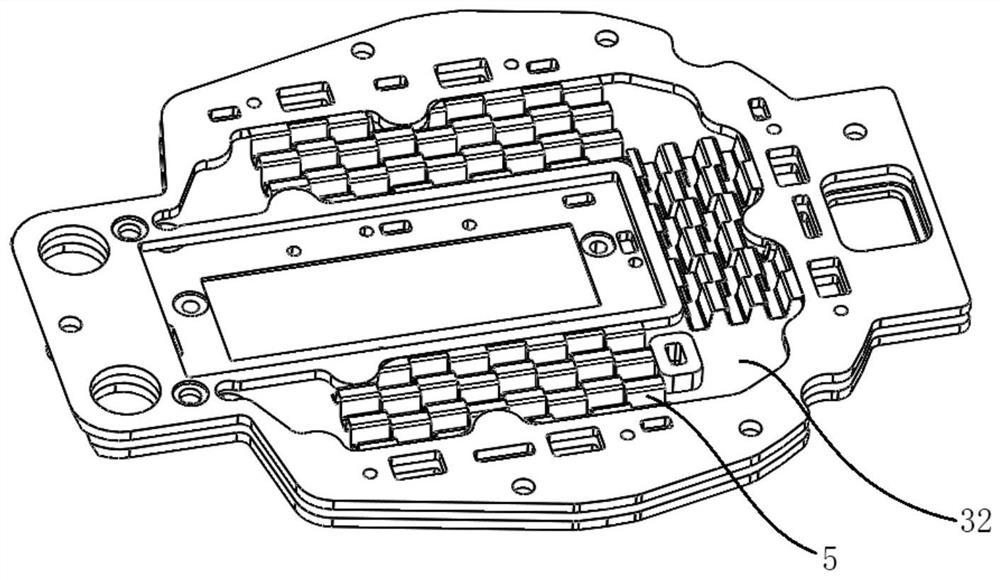

[0042] In this embodiment, the spoiler 5 is a corrugated heat dissipation rib, so that when the cooling medium passes through the corrugated channel, it frequently impacts the hole wall of the heat dissipation rib, thereby increasing the turbulence effect. The spoiler part 5 is connected to the middle plate 3, and the manufacture of the spoiler part 5 can be completed at the same time when the middle plate 3 is manufactured, and the two flow channel openings 23 are all arranged on the lower surface of the bottom plate 2 to cooperate with the water nozzle , which is conducive to the passage of coolant. The upper end surface of the upper plate 4 is provided with a closed-loop sealing groove 43 along the periphery for placing a sealing ring and improving the sealing effect. The lower end surface of the round hole is provided with an annular round platform, which is convenient to cooperate with the faucet. The said round hole is provided with an internal thread, and the internal t...

Embodiment 2

[0049] In this embodiment, the spoiler 5 is a column-shaped heat dissipation rib, the number and shape of the spoiler 5 can be confirmed according to the heat dissipation demand, and the versatility is wide, which can enhance the disturbance effect of the cooling medium fluid, enhance the heat dissipation effect, and ensure the power The mod works fine. The spoiler 5 is connected to the upper end surface of the bottom plate 2 , and the manufacture of the spoiler 5 can be completed at the same time when the bottom plate 2 is manufactured. The two runner ports 23 are both arranged on the upper surface of the upper plate 4 . The runner opening 23 is provided with an internal thread, and the internal thread directly reaches the outer end surface of the runner opening 23 . It is convenient to cooperate with a faucet whose end is an internal thread, and the faucet can be screwed into the internal thread of the runner opening 23 . After the water nozzle is screwed into the flow cha...

Embodiment 3

[0056] In this embodiment, the spoiler 5 has a protruding heat dissipation rib, preferably a serrated protrusion, and the shape of the heat dissipation rib can be individually combined as required to meet the needs of design and use. The two runner ports 23 are both arranged on the upper surface of the upper plate 4, and the upper end surface of the circular hole is provided with a ring-shaped round table, which is convenient for matching with the faucet. External threads are provided on the outer side of the circular platform. It is convenient to cooperate with the water nozzle whose end is external thread to avoid leakage of cooling medium. The flatness of the welding area 42 of the power module is 0.25 mm to obtain better welding effect.

[0057] The processing method of the present embodiment is:

[0058] In the first step, the bottom plate 2, the middle plate 3 and the upper plate 4 are processed by a stamping process, the flow channel opening 23 and the annular circula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flatness | aaaaa | aaaaa |

| Flatness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com