Bean leavening and preparation method thereof

A production method and a technology of fermented products, which are applied in the field of bean fermented products and their production, can solve the problems of low utilization rate of fermented raw materials, affecting the growth of Aspergillus oryzae, and low protease activity in forming koji, so as to achieve low degree of production automation and improve the production of raw materials. Utilization rate and effect of shortening fermentation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

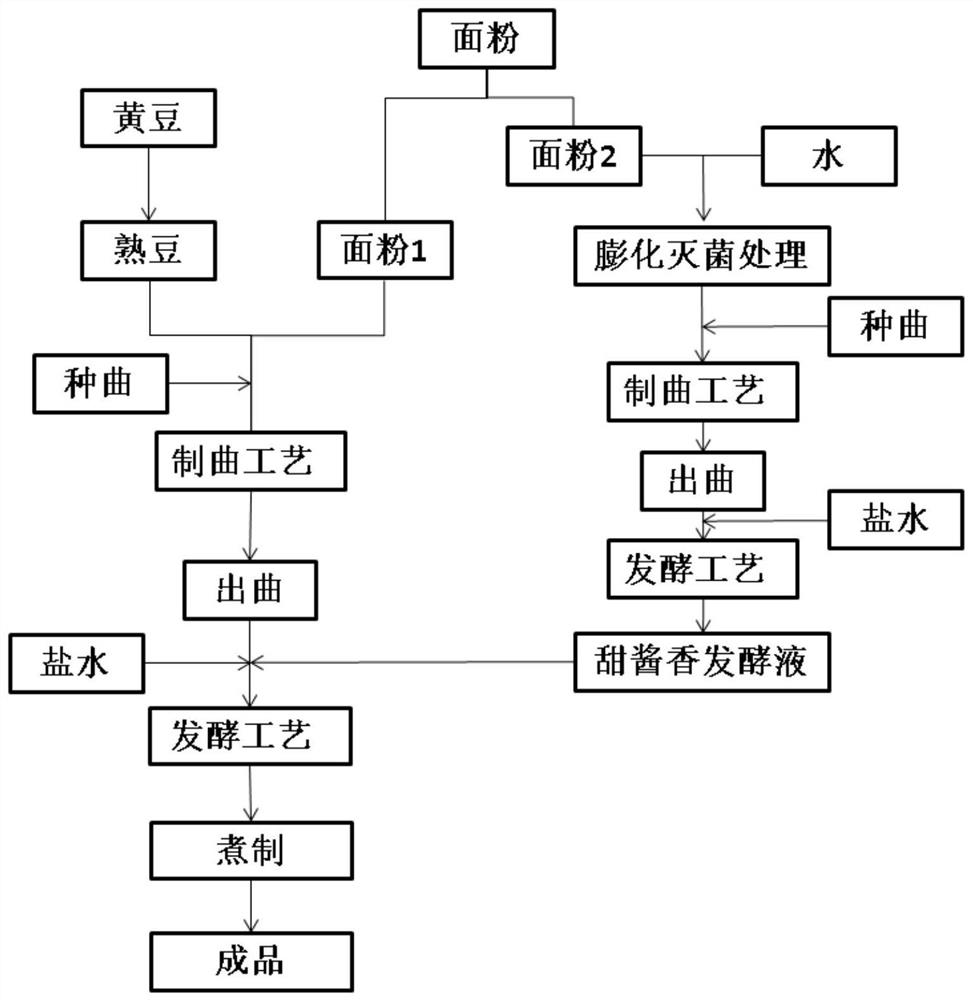

[0066] Present embodiment is a kind of preparation method of soybean paste, technological process is as follows figure 1 As shown, the steps are as follows:

[0067] (1) Soaking beans: select non-genetically modified soybeans, put them into a soaking tank after removing impurities, removing stones, color sorting, and washing beans, add 2.6 times the weight of soybeans, and soak for 6 hours;

[0068] (2) Cooking: The soaked soybeans are cooked in a rotary high-pressure cooking pot, and the cooked beans are required not to be raw, not peeled, not lumpy, evenly soft and hard, and bean grains are complete;

[0069] (3) Cooling inoculation mix: take flour 1 to account for 10% of the weight of cooked beans, and flour 2 to account for 25% of the weight of cooked beans; cool soybeans and flour at 1 to below 40°C, mix the auger evenly and add 0.04% of the weight of cooked beans Aspergillus oryzae, the mixed raw materials are input into the koji chamber through the conveyor belt;

[0...

Embodiment 2

[0076] Present embodiment is a kind of preparation method of soybean paste, and the steps are as follows:

[0077] (1) Soaking beans: select non-transgenic soybeans, remove impurities, remove stones, color sort, and wash the beans, then put them into a soaking tank, add water 3 times the mass of soybeans, and soak for 5 hours;

[0078] (2) Cooking: The soaked soybeans are cooked in a rotary high-pressure cooking pot, and the cooked beans are required not to be raw, not peeled, not lumpy, evenly soft and hard, and bean grains are complete;

[0079] (3) Cooling inoculation mixing material: take flour 1 accounting for 20% of the weight of cooked beans, flour 2 accounting for 20% of the weight of cooked beans, cooling soybeans and flour 1 to below 40°C, auger mixing evenly and adding 0.08% of the weight of cooked beans Aspergillus oryzae, the mixed raw materials are input into the koji chamber through the conveyor belt;

[0080] (4) Koji-making process: the mixed raw materials in...

Embodiment 3

[0086] Present embodiment is a kind of preparation method of soybean paste, and the steps are as follows:

[0087] (1) Soaking beans: select non-transgenic soybeans, remove impurities, remove stones, color sort, and wash the beans, then put them into a soaking tank, add water 3 times the mass of soybeans, and soak for 4 hours;

[0088] (2) Cooking: The soaked soybeans are cooked in a rotary high-pressure cooking pot, and the cooked beans are required not to be raw, not peeled, not lumpy, evenly soft and hard, and bean grains are complete;

[0089] (3) Cooling inoculation mixing material: get flour 1 and account for 25% of the weight of cooked beans, flour 2 accounts for 15% of the weight of cooked beans, cool soybeans and flour 1 to 40°C and auger the mixture evenly and add rice with 0.12% of the weight of cooked beans Aspergillus, the mixed raw materials are input into the koji chamber through the conveyor belt;

[0090] (4) Koji-making process: the mixed raw materials in st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com