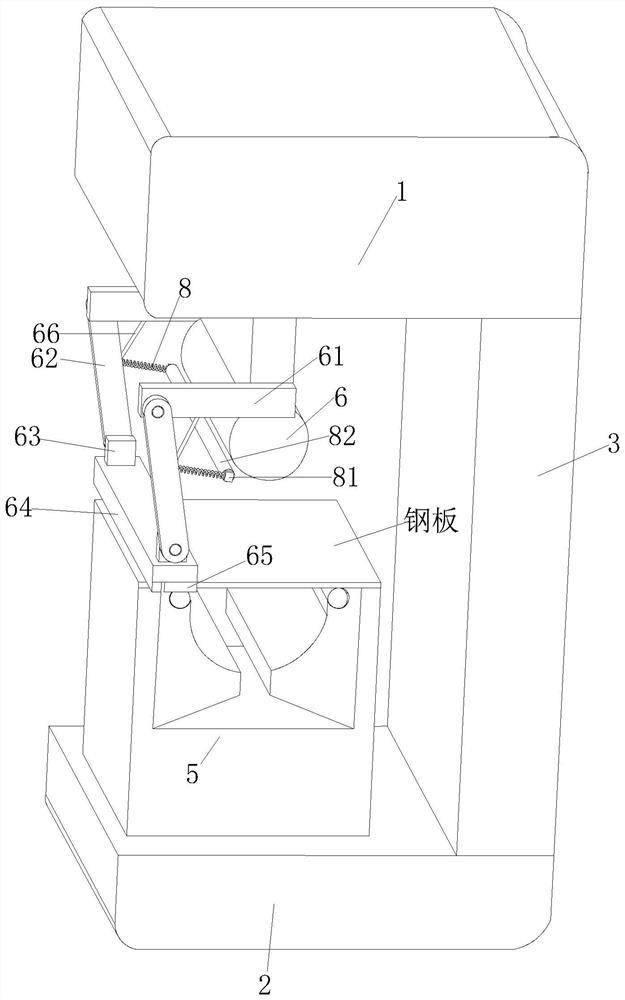

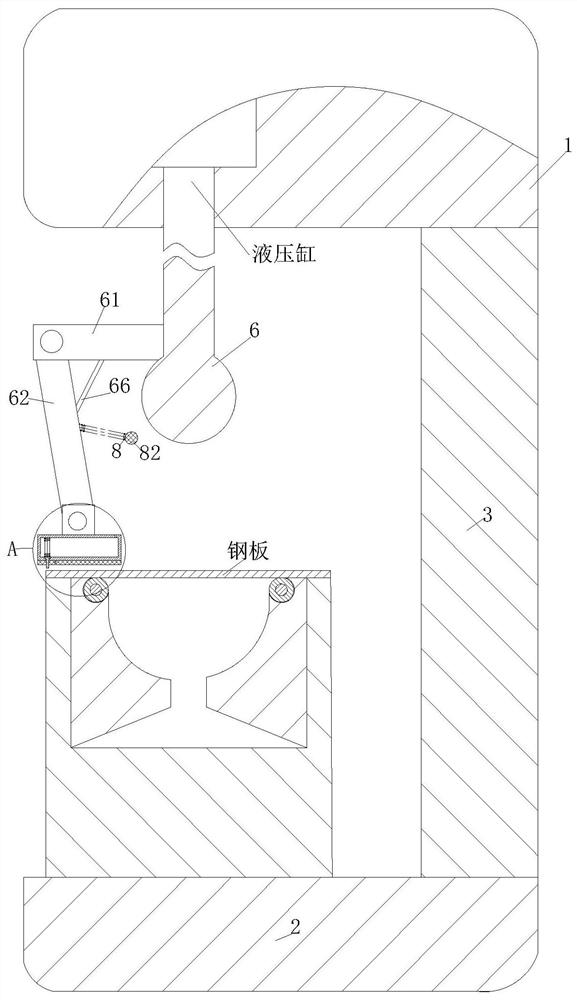

U-shaped steel plate bending machine

A bending machine and steel plate technology, applied in the field of steel plate processing, can solve the problems of scratching the steel plate, unable to clean the steel plate, increasing the manufacturing cost of the steel plate, etc., to prevent the adhesion of impurities and dust, ensure the implementation effect, and ensure the effect of cleanliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

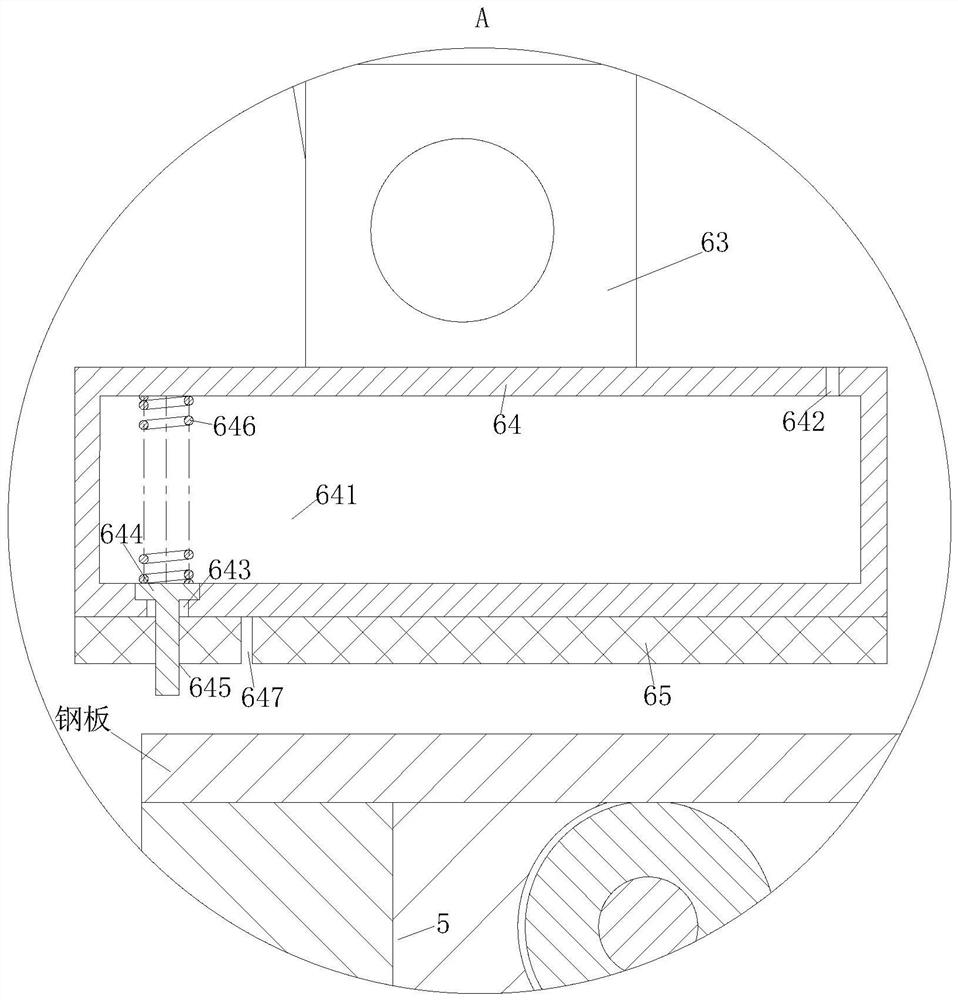

[0040] As an embodiment of the present invention, the step hole 643, the push rod 644, the through hole 645 and the return spring 646 are arranged away from the support plate 3; the end surface of the cleaning layer 65 away from the cleaning strip 64 is provided with a cutting groove 647; The cutting groove 647 runs through the cleaning layer 65, and the cutting groove 647 is arranged close to the through hole 645. The cutting groove 647 divides the cleaning layer 65 into two parts that are close to and far from the support plate 3;

[0041] During work, along with the decline of the position of the cleaning strip 64, the push rod 644 in the cleaning strip 64 is jacked up, so that the lubricating oil in the cavity 641 penetrates into the cleaning layer 65 away from the support plate 3 through the step hole 643; After the cleaning layer 65 of the plate 3 cleans the surface of the steel plate, the cleaning layer 65 away from the support plate 3 brushes the lubricating oil on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com