High-strength round chain production polishing device

A polishing device and high-strength technology, which is applied in the direction of grinding drive devices, grinding/polishing equipment, surface polishing machine tools, etc., can solve the problems of poor polishing effect and low efficiency, and achieve the effect of ensuring efficiency and good polishing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

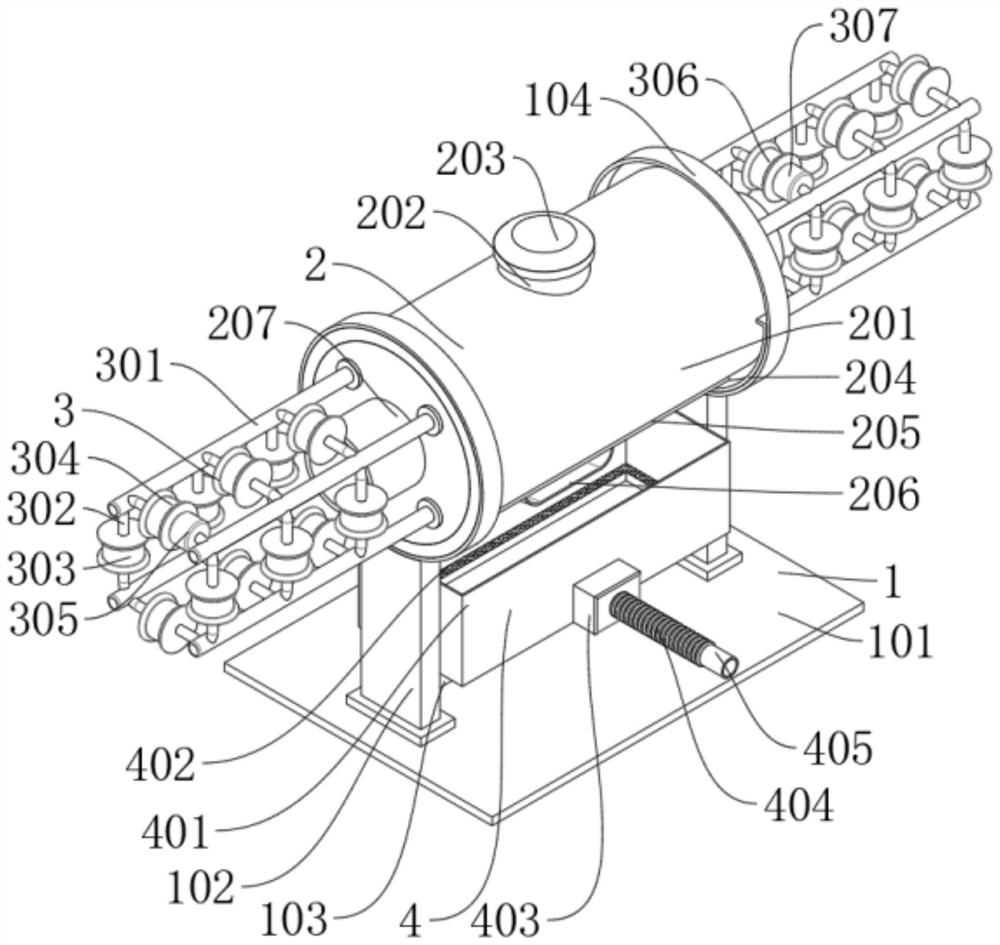

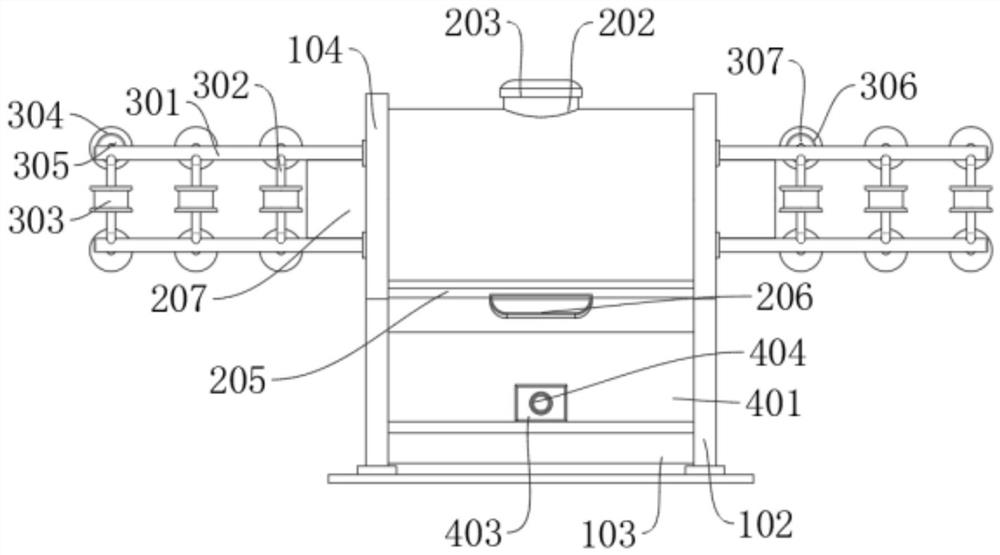

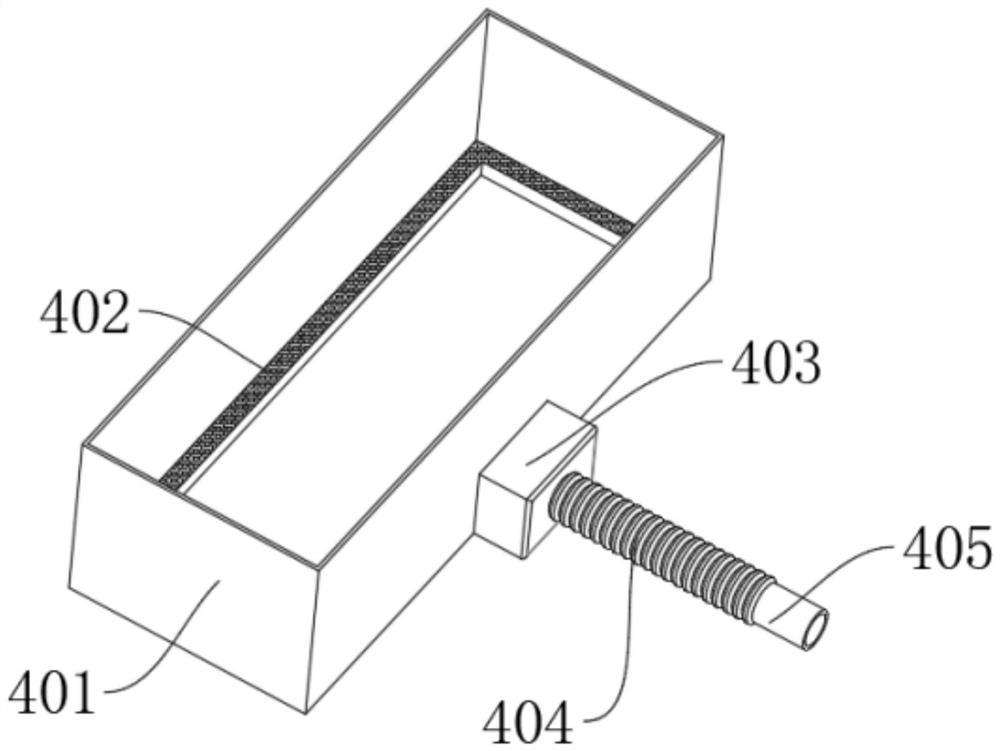

[0030] see Figure 1-Figure 4 , the present invention provides a polishing device for the production of high-strength round chains: it includes a carrying mechanism 1, a polishing mechanism 2, and a waste suction mechanism 4. A polishing mechanism 2 is installed inside the carrying mechanism 1, and a waste suction mechanism is installed on the lower part of the polishing mechanism 2. 4. It also includes the chain feeding mechanism 3 for the smooth entry and exit of the round chain, and the chain feeding mechanism 3

[0031] Including connecting main rod 301, connecting pole 302, driven roller 303, chain feeding roller 304, first motor 305, chain output roller 306, second motor 307, connecting main rod 301 is connected to the two ends of polishing mechanism 2 by bolts. There are four corners on the side, and connecting rods 302 are installed on the connecting main rod 301, and driven rollers 303 are connected between the connecting rods 302 through bearings, and the driven roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com