Ag<+>-loaded hierarchical porous molecular sieve for removing sulfur-containing volatile organic compounds, preparation method and application thereof

A technology of volatile organic compounds and molecular sieves, which is applied in the field of environmental pollutant treatment, can solve problems such as difficult adsorption by adsorbents, low adsorption capacity, and VOCs crowding, so as to avoid desorption of sulfur-containing VOCs, increase adsorption capacity, and enhance The effect of adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

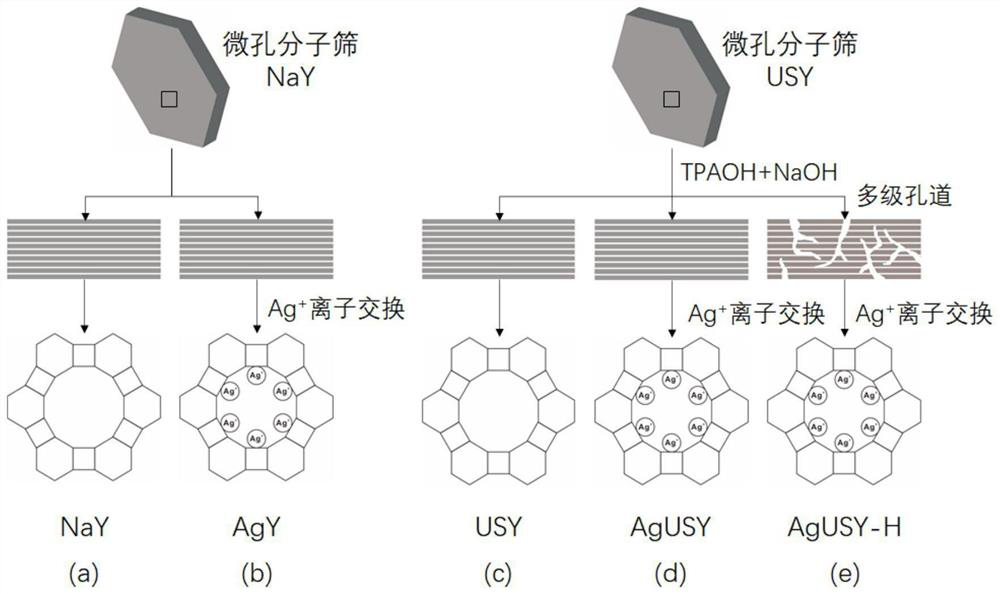

[0027] Embodiment 1 of the present application provides a method such as figure 1 (e) The Ag+-supported hierarchical porous molecular sieve (AgUSY-H) for the removal of sulfur-containing volatile organic compounds.

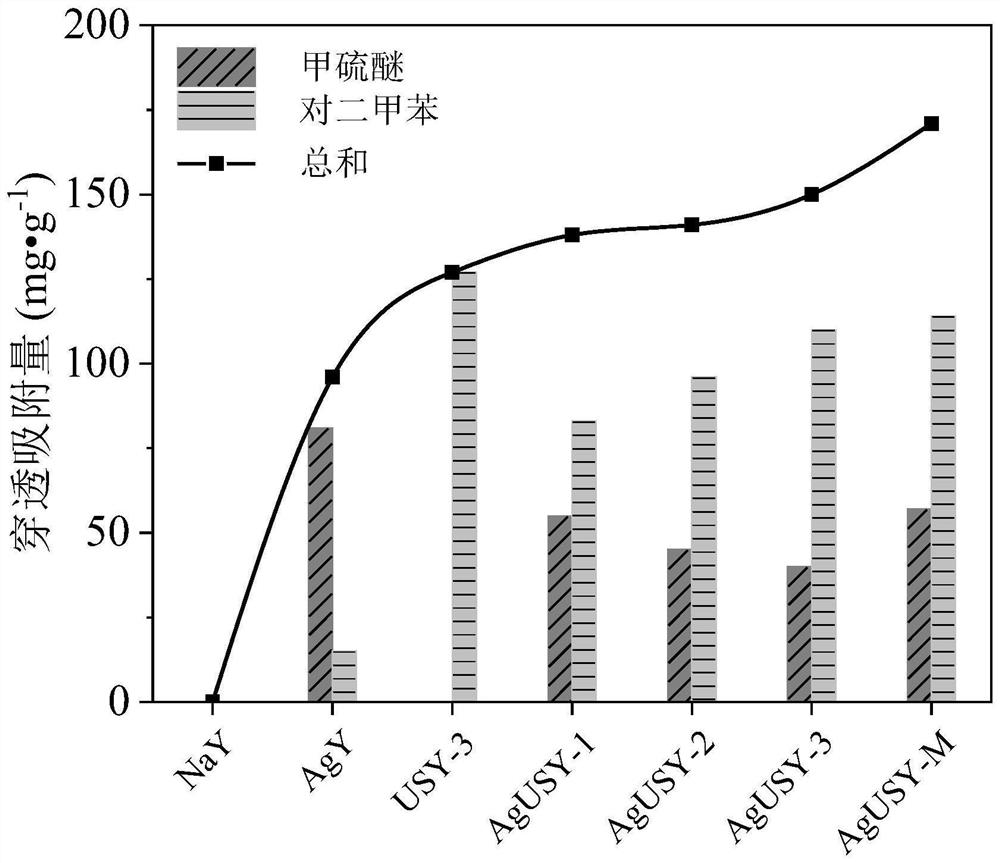

[0028] The multi-stage pore molecular sieve is loaded with Ag by ion exchange. +, to achieve the adsorption of sulfur-containing volatile organic compounds; Ag+-loaded multi-stage pore molecular sieves have both mesopore structure and micropore structure, which can strengthen the transfer of adsorbates inside the molecular sieve, and prevent small molecule sulfur-containing VOCs from quickly entering the interior of the molecular sieve and interacting with the adsorption sites. Pore blockage caused by point binding, molecular sieve adsorption capacity decline, and small molecule sulfur-containing VOCs crowding out other VOCs adsorption sites lead to molecular sieves being unable to achieve simultaneous efficient adsorption of multi-component VOCs; actual VOCs ex...

Embodiment 2

[0032] Example 2 of the present application provides Ag in Example 1. + The preparation method of the USY molecular sieve (AgUSY-H) of load, the preparation process of AgUSY-H molecular sieve comprises the steps:

[0033] 1. Using alkali treatment method to modify USY-3 molecular sieve with multi-stage channels:

[0034] Add commercial USY-3 molecular sieve into the mixed alkali solution, heat and stir, wash, filter, dry, and roast to obtain multi-level porous USY molecular sieve; USY molecular sieve dissolves Si in the molecular sieve skeleton through alkali treatment, so that a large number of mesoporous structures are formed inside the molecular sieve , but the dissolution rate needs to be controlled. Excessive dissolution may cause the molecular sieve skeleton to be completely destroyed, while TPAOH contains organic groups, which can be attached to the surface of the molecular sieve and protect the molecular sieve during the dissolution process.

[0035] 2. Commercial USY...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com