Method for improving selective laser cladding NiTi performance by controlling parameters

A technology of laser selective cladding and parameter control, applied in the field of material 3D printing, to achieve the effects of excellent tensile properties and cycle performance, high safety factor and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

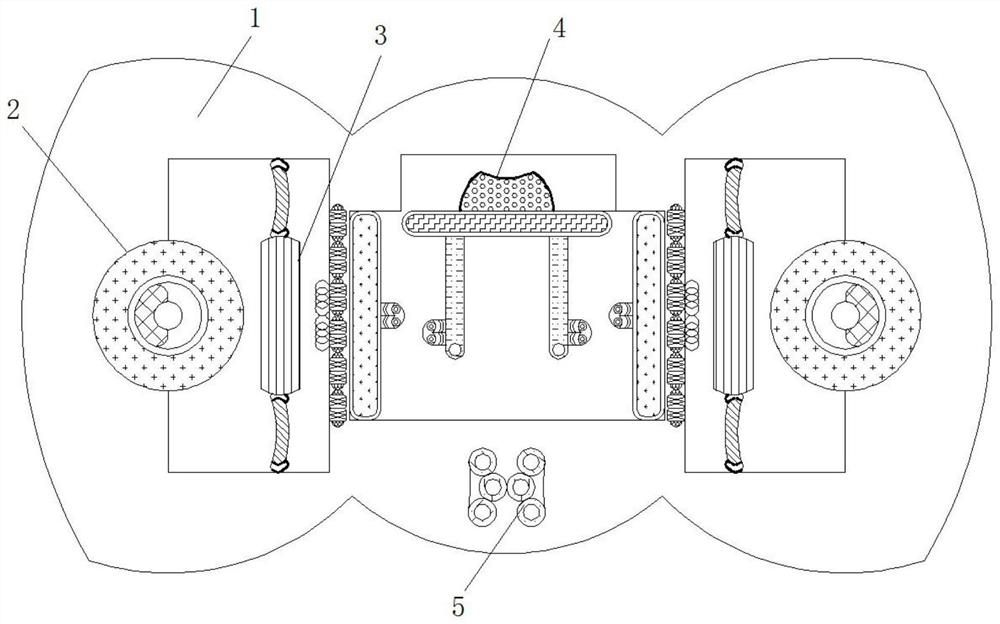

[0040] see Figure 1-2 , a vacuum dryer used in the production process as described above, including a device housing 1, and also includes an electromagnetic wave detection component 2, a vibration sensing component 3, and a humidity sensing component 4, and the electromagnetic wave detection component 2 is fixedly connected inside the device housing 1 , used to detect the strength of the electromagnetic field where the vacuum drying equipment is located. The vibration sensing component 3 is fixedly connected to the inside of the equipment casing 1, and is used to detect the ambient humidity of the vacuum drying equipment. The inside of the equipment casing 1 is fixedly connected to a humidity sensing component 4 , used to detect whether the vacuum drying equipment is in a state of severe vibration;

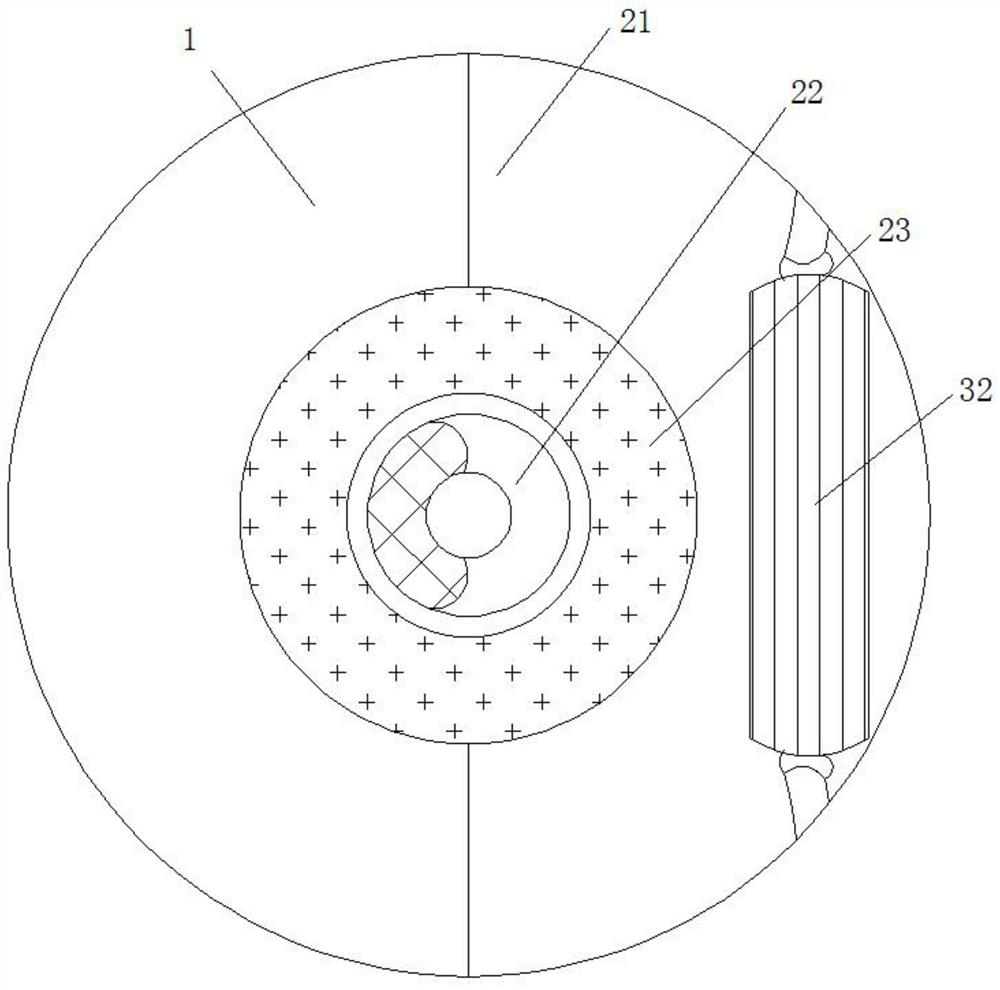

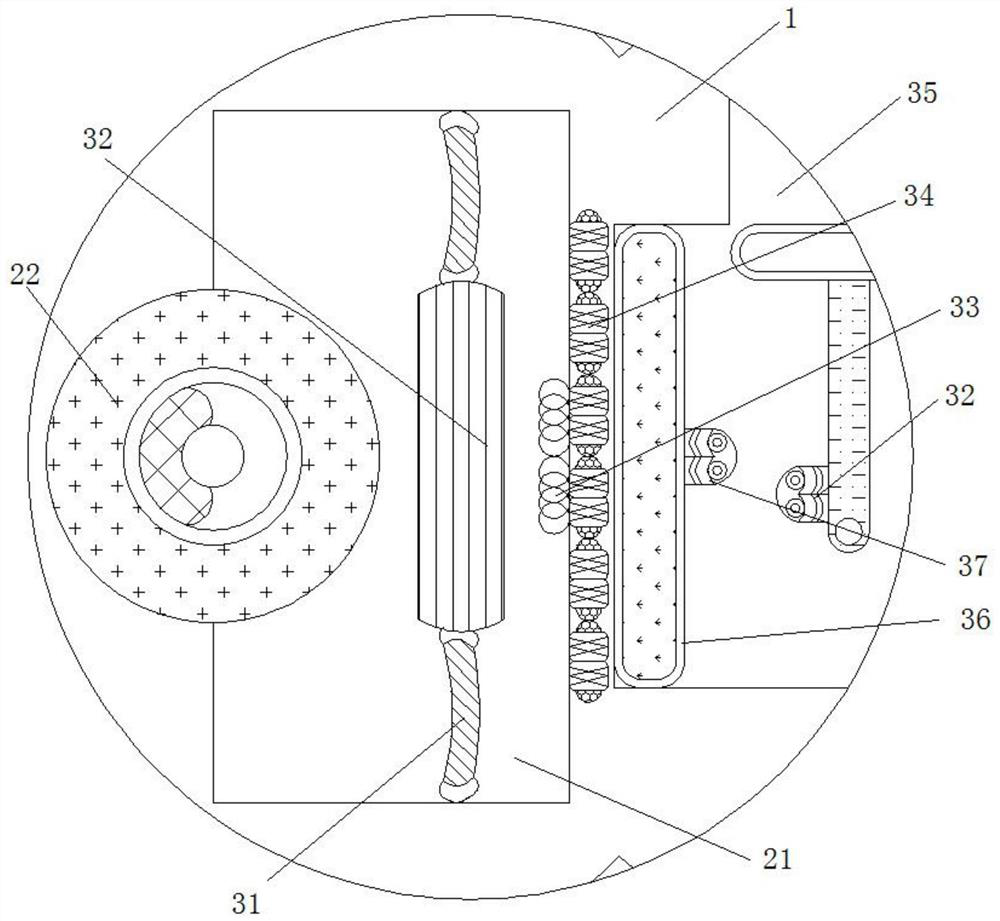

[0041]The electromagnetic wave detection component 2 includes a mounting groove 21, a thermistor 22, and a wave-absorbing material 23. The inside of the equipment housing 1 is pr...

Embodiment 2

[0043] see Figure 1-4 , a vacuum dryer used in the production process as described above, including a device housing 1, and also includes an electromagnetic wave detection component 2, a vibration sensing component 3, and a humidity sensing component 4, and the electromagnetic wave detection component 2 is fixedly connected inside the device housing 1 , used to detect the strength of the electromagnetic field where the vacuum drying equipment is located. The vibration sensing component 3 is fixedly connected to the inside of the equipment casing 1, and is used to detect the ambient humidity of the vacuum drying equipment. The inside of the equipment casing 1 is fixedly connected to a humidity sensing component 4 , used to detect whether the vacuum drying equipment is in a state of severe vibration;

[0044] The electromagnetic wave detection component 2 includes a mounting groove 21, a thermistor 22, and a wave-absorbing material 23. The inside of the equipment housing 1 is p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com