Modular reducing pipeline inner plugging device, driving mechanism and coordination ring

A technology of driving mechanism and occluder, which is applied in the direction of pipe components, mechanical equipment, pipes/pipe joints/fittings, etc. It can solve the difficult plugging operation of large-diameter and high-pressure pipelines, and the internal occluder cannot complete the plugging task , the radius of the internal occluder is very strict, etc., to achieve good passability and plugging adaptability, high plugging pressure, and improved load distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] see Figure 1 to Figure 14 , the present invention provides a technical solution:

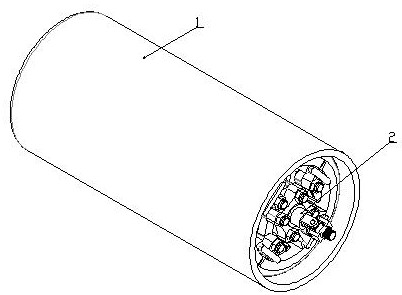

[0068] Such as figure 1 , figure 2 As shown, it is a schematic diagram of the overall structure layout of the present invention. A modular variable-diameter pipeline internal occluder of the present invention mainly includes two parts: a sealing barrel 1 and a pressing mechanism 2; the sealing barrel 1 is a deformable Made of rubber material, its structure is a cylindrical barrel-shaped structure with one end open;

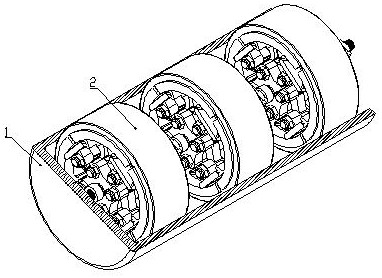

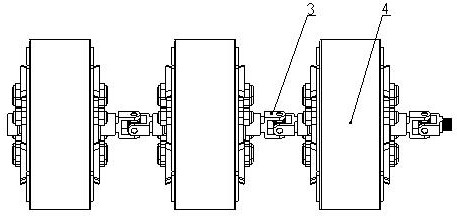

[0069] Such as figure 2 , image 3 As shown, it is a schematic diagram of the structural layout of the pressing mechanism of the present invention. The pressing mechanism 2 is a deformable serial structure connected by a plurality of variable diameter modules 4 through universal joints 3, which is installed inside the sealed barrel 1 to seal During the operation, the sealing barrel 1 can be pressed tightly on the inner wall of the pipeline through each variable diamet...

Embodiment 2

[0079] see Figure 1 to Figure 14 , the present invention provides a technical solution:

[0080] Such as figure 1 , figure 2 As shown, it is a schematic diagram of the overall structure layout of the present invention. A modular variable-diameter pipeline internal occluder of the present invention mainly includes two parts: a sealing barrel 1 and a pressing mechanism 2; the sealing barrel 1 is a deformable Made of rubber material, its structure is a cylindrical barrel-shaped structure with one end open;

[0081] Such as figure 2 , image 3 As shown, it is a schematic diagram of the structural layout of the pressing mechanism of the present invention. The pressing mechanism 2 is a deformable serial structure connected by a plurality of variable diameter modules 4 through universal joints 3, which is installed inside the sealed barrel 1 to seal During the operation, the sealing barrel 1 can be pressed tightly on the inner wall of the pipeline through each variable diamet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com