Planarization etchback method after groove is filled with medium

A trench filling and planarization technology, used in electrical components, circuits, semiconductor/solid-state device manufacturing, etc., can solve the problems of metal voids affecting the yield of silicon-based surface, increasing metal contact resistance, and poor uniformity. Follow-up process defects, reduce height difference, good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

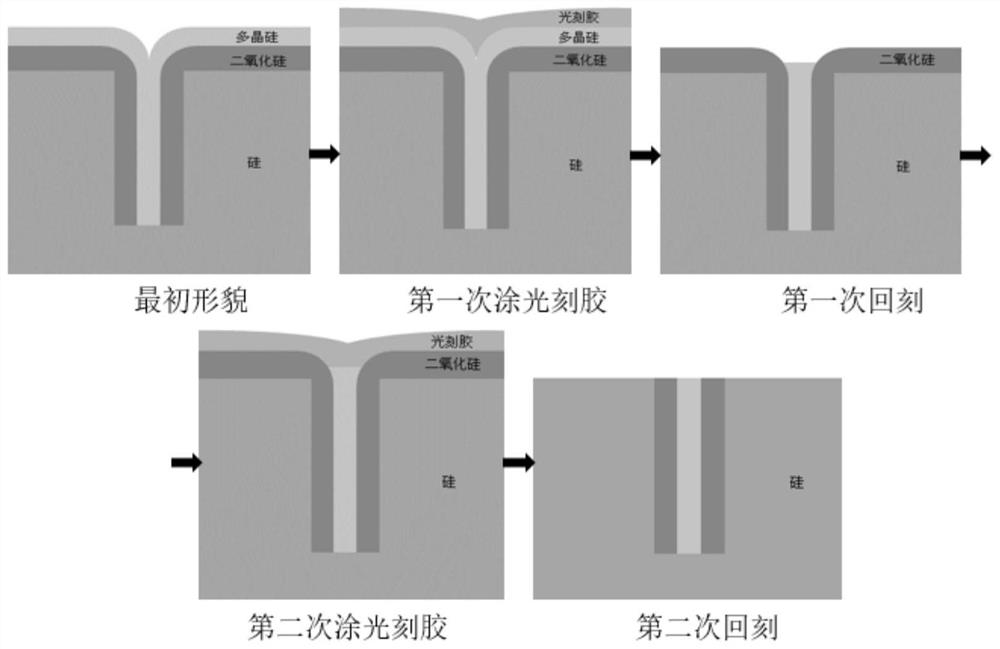

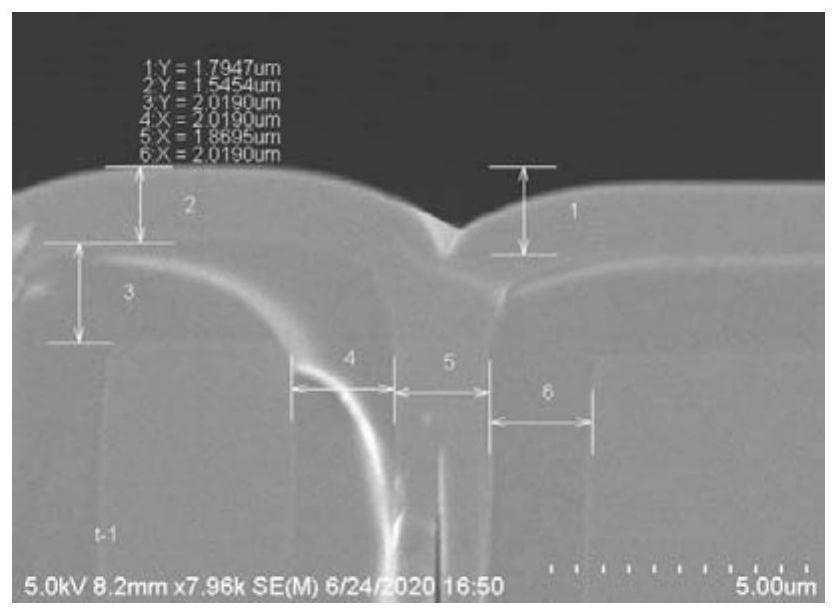

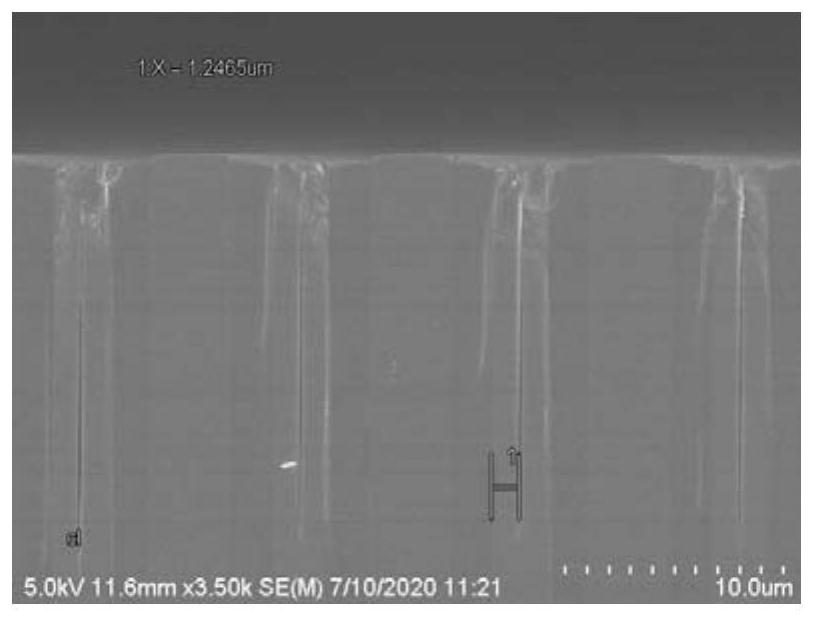

[0039] Such as figure 2 As shown, a 6-inch silicon wafer is selected, and a 2.0 μm thick silicon dioxide layer is grown in the silicon wafer groove first, and then a 1.5 μm thick polysilicon layer is filled. After filling, the thickness of the polysilicon layer on the surface of the silicon wafer is 1.5μm, the thickness of the silicon dioxide layer is 2.0μm, the first photoresist coating is performed, and the thickness of the photoresist is After the surface is planarized, the first etching is carried out, using AMAT CENTURA5200 polysilicon etching machine, the pressure is 4mTorr, the Source power is 475W, and the Bias power is 100W; the etching gas is HBr and Cl 2 and HeO 2 , where the flow rate of HBr is 20sccm, Cl 2 The flow rate is 68sccm, HeO 2 The flow rate of the polysilicon layer is 2sccm, and the etching rate of the polysilicon layer is / min, the etching rate of the photoresist layer is / min, remove all the photoresist layer and polysilicon layer on the top o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com