Warm heading machine

A technology of warm heading machine and frame, which is applied to forging presses, forging presses, forging press driving devices, etc., which can solve the problems of poor stability, unfavorable maintenance, and large volume of supercharging devices, so as to avoid power loss and prevent failure , small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

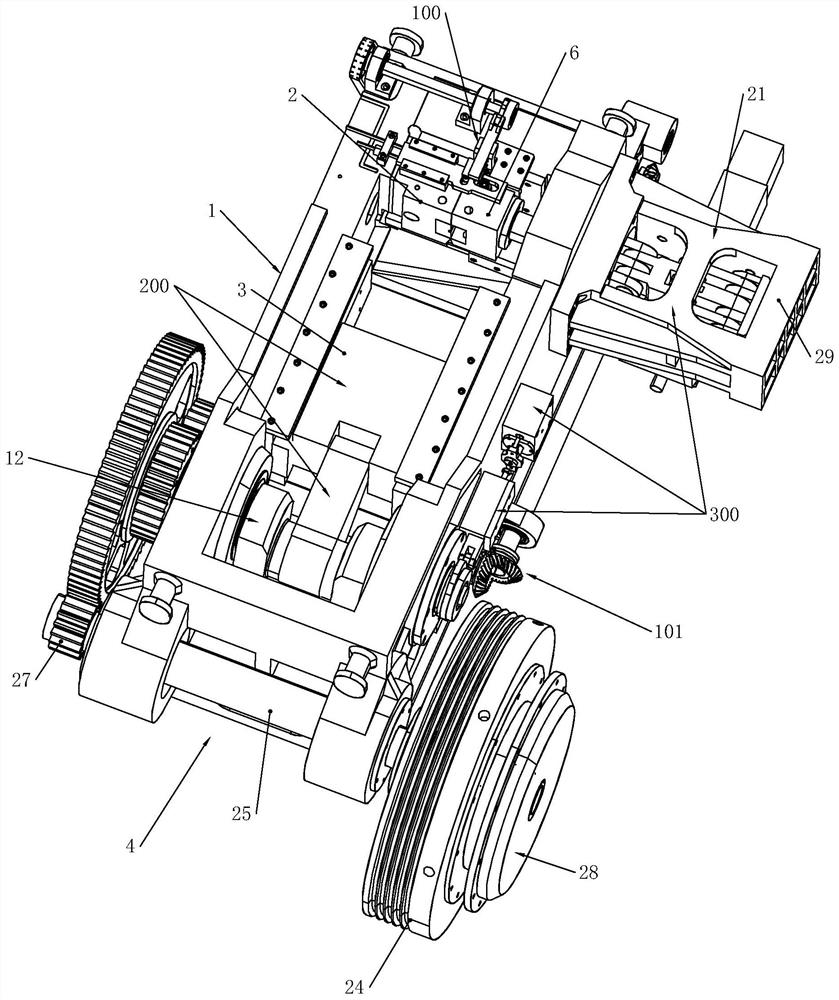

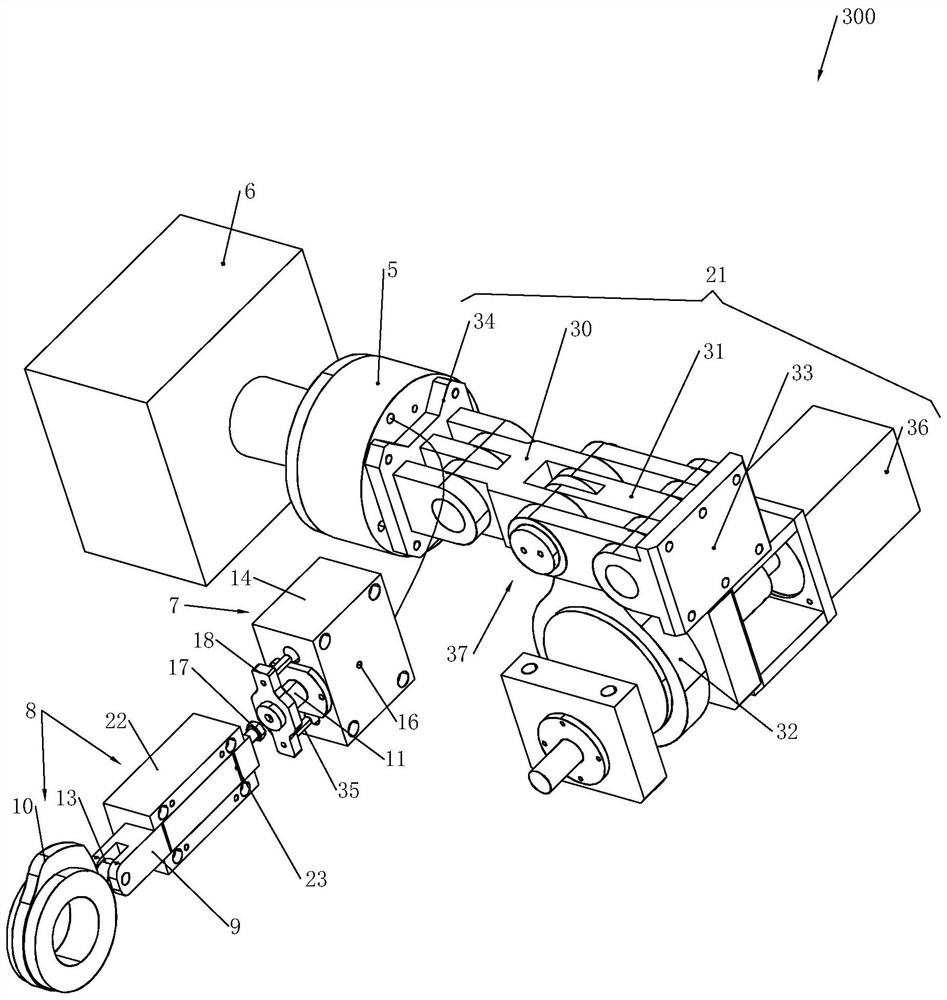

[0061] Such as figure 1 As shown, a warm heading machine includes a frame 1, on which a power unit 4, an actuator 200 connected to the power unit 4, a fixed mold 2, a movable mold locking device 300 and a blanking device 100 are installed on the frame 1, The movable mold locking device 300 can drive the movable mold 6 to move and close with the fixed mold 2 to form a mold cavity. The power device 4 drives the actuator 200 to move and push the raw material into the mold cavity 103 for molding. The device 100 exits the mold cavity 103 .

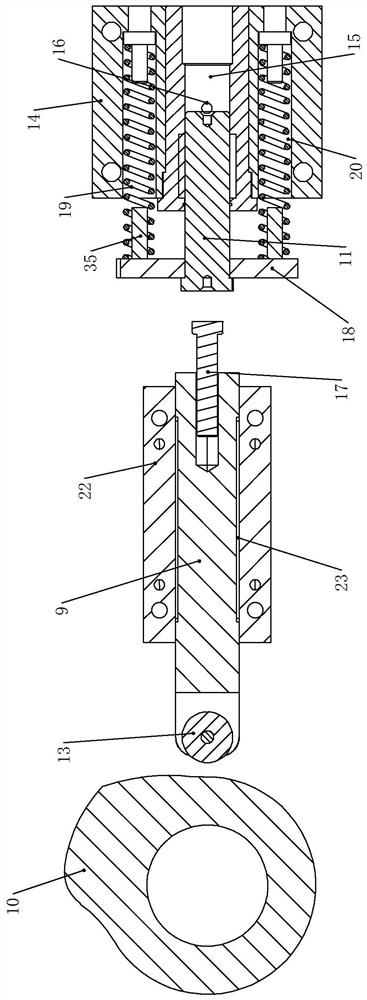

[0062] Power unit 4 comprises motor and crankshaft 12, and described motor is connected with flywheel 24 by transmission belt, drives flywheel 24 to rotate simultaneously when motor rotates; One end is provided with a gear 26, and the other end of the transmission shaft 25 is provided with a driving wheel 27 meshing with the gear 26. Through the above-mentioned structure to control the rotation of the crankshaft 12, the user can move between t...

Embodiment 2

[0121] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that the driving member can directly use a crank, and the rotation of the crankshaft 12 moves the slide rod 9 through the crank to push the booster piston 11 to perform the booster operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com