Novel material ceramic plate perforating machine

A technology of ceramic plate and punching machine, which is applied to stone processing tools, stone processing equipment, work accessories, etc., can solve the problems of brittleness of ceramic plates and the inability to clamp the curved ceramic plates, and achieve the effect of reducing flying everywhere.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

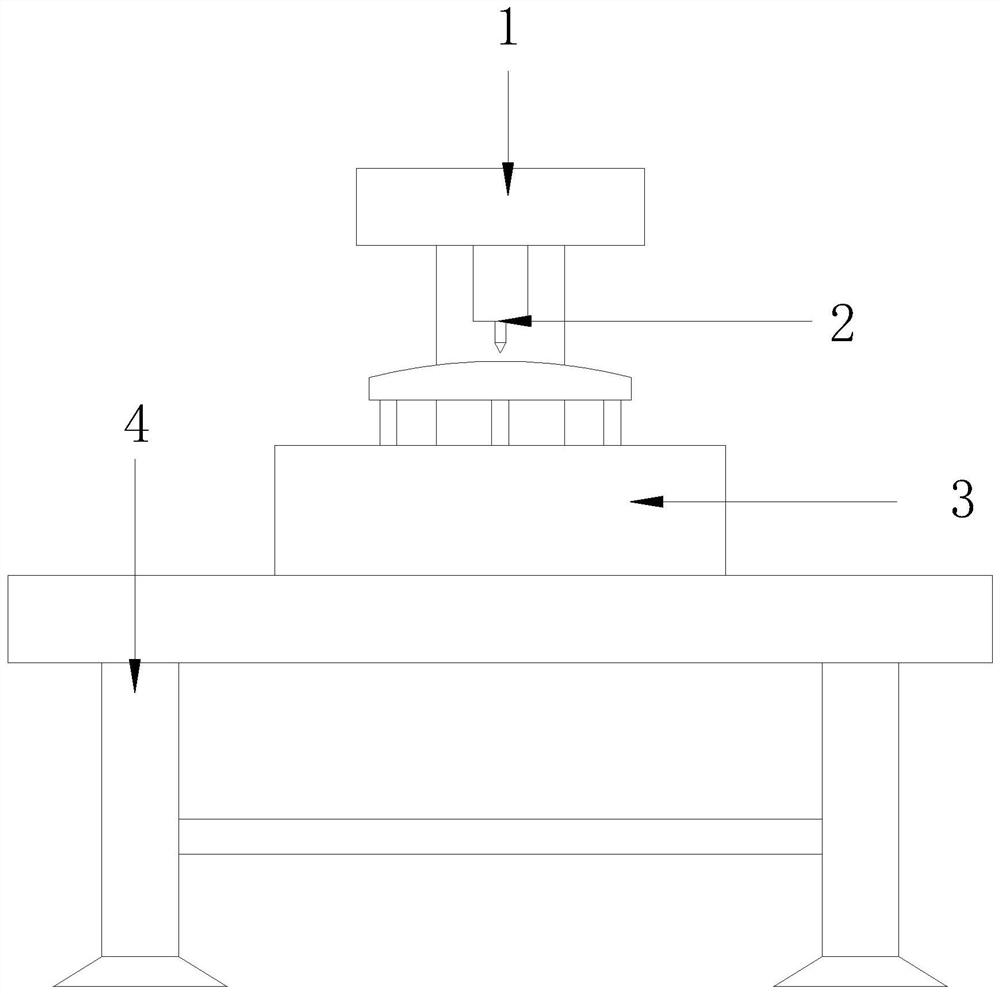

[0026] Such as figure 1 As shown, the present invention provides a new material ceramic plate punching machine, its structure includes a machine head structure 1, a drill bit 2, a fixing mechanism 3, a machine base 4, the surface of the machine base 4 is equipped with a fixing mechanism 3, and the machine The machine head structure 1 is fixed on the seat 4, and the machine head structure 1 is movably connected with the drill bit.

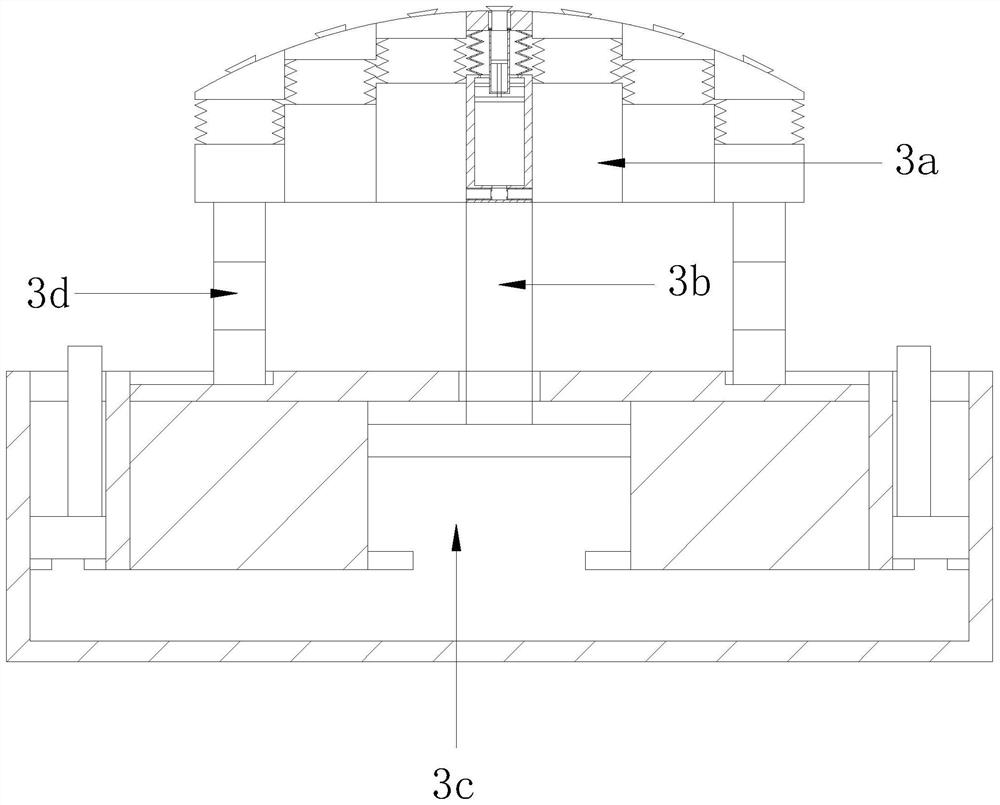

[0027] Such as Figure 2-3 As shown, the fixing mechanism 3 mentioned in the embodiment of the present invention includes a fixing tissue 3a, a pressing rod 3b, a base 3c, and a telescopic sliding rod 3d. The bottom of the fixing tissue 3a is equipped with a pressing rod 3b and a telescopic sliding rod 3d. There are two telescopic sliding rods 3d located on both sides of the pressing rod 3b, the pressing rods 3b cooperate with the base 3c, the telescopic sliding rods 3d are slidingly connected with the base 3c, and the base 3c is installed on the ...

Embodiment 2

[0036] Such as Figure 1-3 As shown, the present invention provides a new material ceramic plate punching machine, its structure includes a machine head structure 1, a drill bit 2, a fixing mechanism 3, a machine base 4, the surface of the machine base 4 is equipped with a fixing mechanism 3, and the machine The machine head structure 1 is fixed on the seat 4, and the machine head structure 1 is movably connected with the drill bit. The fixed mechanism 3 includes a fixed organization 3a, a pressing bar 3b, a base 3c, and a telescopic slide bar 3d. The bottom of the fixed organization 3a is installed There are compression rods 3b and telescopic sliding rods 3d. There are two telescopic sliding rods 3d located on both sides of the compression rods 3b. The compression rods 3b cooperate with the base 3c, and the telescopic sliding rods 3d are slidably connected to the base 3c. The base 3c is installed on the surface of the machine base 4 .

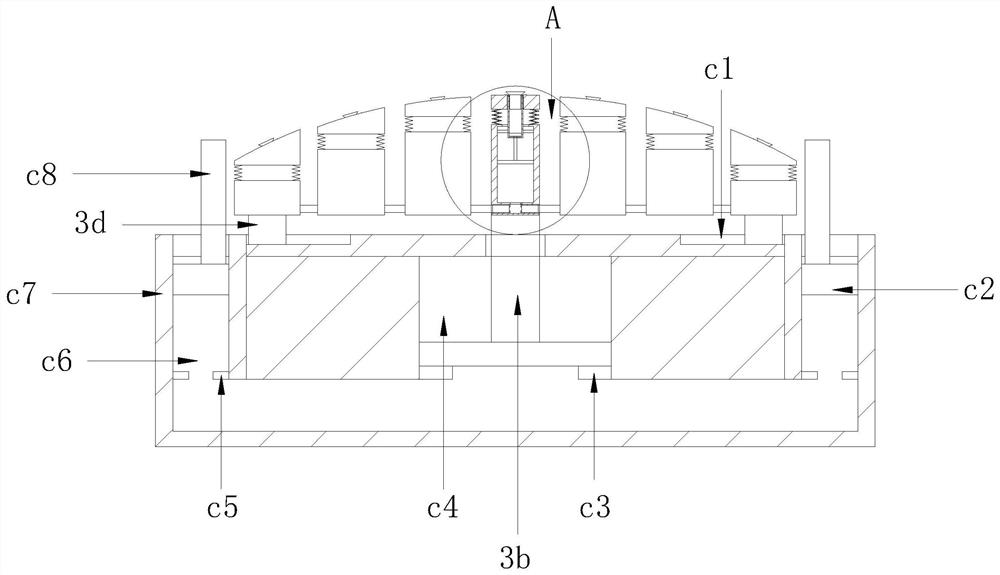

[0037] Such as Figure 4 As shown, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com