Closed air-cooled brace pelletizing system

A closed, air-cooled technology, used in the field of plastic processing, can solve the problems of easy loss of activity and achieve the effects of preventing pollution, shortening length and preventing deactivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

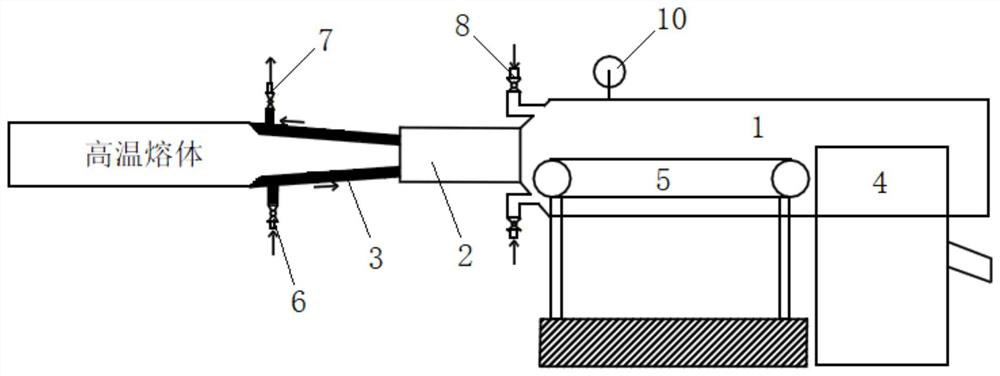

[0024] In order to further understand the content of the present invention, in conjunction with the attached figure 1 And embodiment describe the present invention in detail.

[0025] combined with figure 1 , a closed air-cooled strand pelletizing system in this embodiment includes a sealed bin 1 through which low-temperature high-purity nitrogen flows. The sealed bin 1 is provided with at least one nitrogen gas inlet valve 8. The sealed bin 1 1 is provided with a pressure relief valve, the pressure in the sealed chamber 1 is 0.1-0.3Mpa; the mouth die 2 communicates with the sealed chamber 1 and is installed on the left side of the sealed chamber 1; the low-temperature jacket 3 is connected to the mouth die 2 Connected, there is a low-temperature liquid flowing inside, and the material passes through the low-temperature jacket 3 and enters the die 2 to cut strips; the pelletizer 4, the feed port of the pelletizer 4 is arranged in the sealed chamber 1; The conveying device 5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com