Railway tunnel sludge clearing vehicle

A technology for cleaning vehicles and tunnels, applied in waterway systems, cleaning sewer pipes, water supply devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

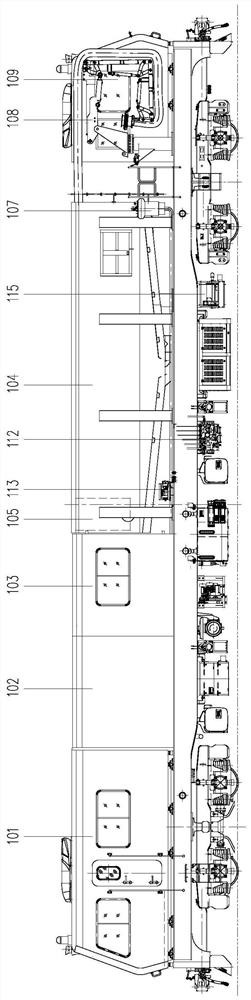

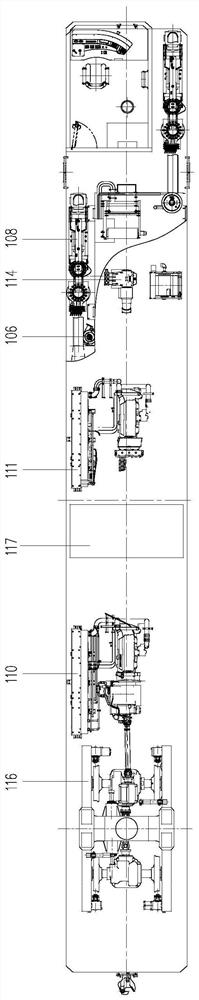

[0069] figure 1 A schematic structural view of the railway tunnel sludge cleaning vehicle of the present embodiment is shown; figure 2 A schematic diagram of the bottom structure of the railway tunnel sludge cleaning vehicle of this embodiment is shown.

[0070] The railway tunnel sludge cleaning vehicle of the present embodiment comprises a rail car main body, a dredging system and a sewage suction system, such as figure 1 , figure 2 As shown, a front control room 101, a water tank 102, a fan room 103, a silo 104, a water vapor separation device 105, a discharge pump 106, a sewage circulation system 107, two left and right suction arms 108, and a rear control room are set on the main body of the rail car. 109; the lower part of the main body of the rail car is equipped with a car body power transmission system 110, an operating power system 111, a braking system 112, a hydraulic system 113, a pressurizing pump 114, a hydraulic hose reel 115, two bogies 116, a fuel tank an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com