Reaction device for producing hydrogen and oxygen by electrolyzing water

A reaction device and water electrolysis technology, applied in the electrolysis process, electrolysis components, electrodes, etc., can solve the problems of high price of proton exchange membrane electrolysis water equipment, restrictions on large-scale promotion and application of proton exchange membrane electrolysis water hydrogen production technology, and achieve Improve energy conversion efficiency, wide operating power range, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

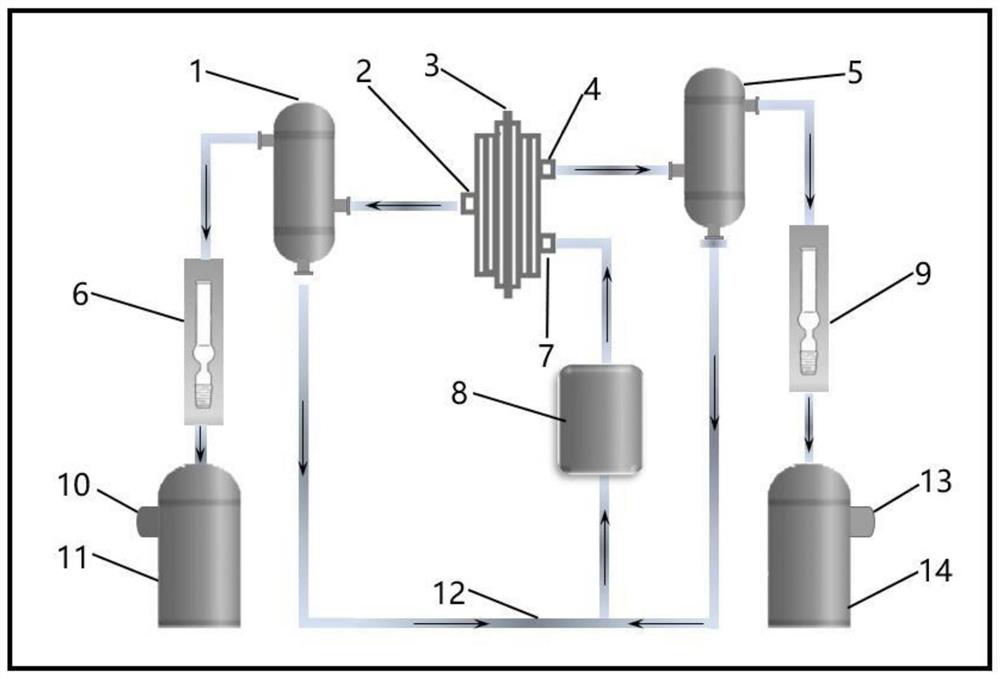

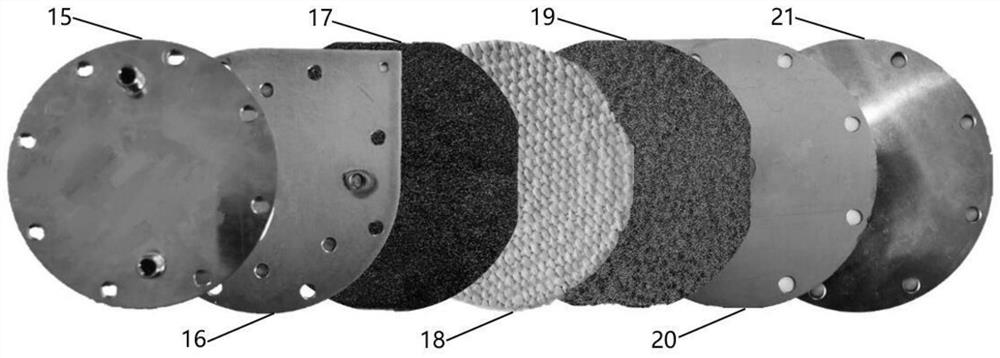

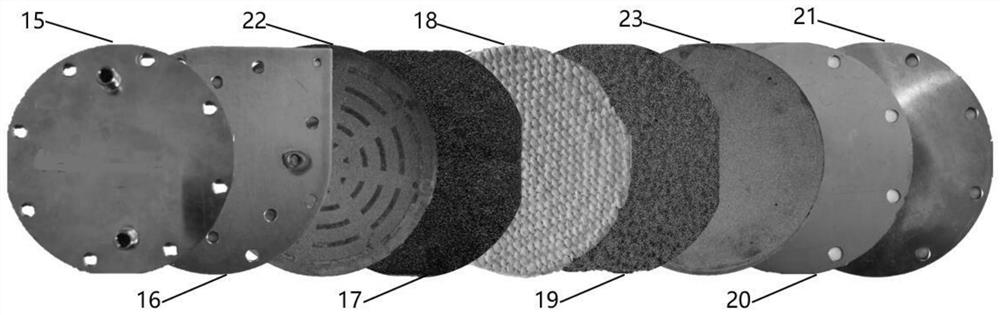

[0025] Two pieces of nickel foam are selected as the self-supporting transition metal cathode material and the self-supporting transition metal anode material respectively, and thus assembled into a cathode end plate, cathode plate, nickel foam, asbestos, nickel foam, anode plate and anode end plate Electrolyzer without current collector and self-supporting electrode without proton exchange membrane and other components, the schematic diagram of component disassembly is shown in figure 2 shown. A reaction device for hydrogen production and oxygen production by electrolysis of water according to the present invention comprises the above-mentioned electrolytic cell without a current collector and without a proton exchange membrane self-supporting electrode, and two sets of gas-liquid separators (used to separate hydrogen and lye and oxygen and lye), two sets of drying tubes (for drying hydrogen and oxygen respectively), lye tank, hydrogen storage tank, oxygen storage tank and s...

Embodiment 2

[0028] Two pieces of iron foam are selected as self-supporting transition metal cathode material and self-supporting transition metal anode material respectively, thus assembled into a cathode end plate, cathode plate, foam iron, asbestos, foam iron, anode plate and anode end plate Electrolyzer without current collector and self-supporting electrode without proton exchange membrane and other components, the schematic diagram of component disassembly is shown in figure 2 shown. A reaction device for hydrogen production and oxygen production by electrolysis of water according to the present invention comprises the above-mentioned electrolytic cell without a current collector and without a proton exchange membrane self-supporting electrode, and two sets of gas-liquid separators (used to separate hydrogen and lye and oxygen and lye), two sets of drying tubes (for drying hydrogen and oxygen respectively), lye tank, hydrogen storage tank, oxygen storage tank and silicone tube.

[...

Embodiment 3

[0031] Two pieces of foamed iron-nickel are selected as the self-supporting transition metal cathode material and the self-supporting transition metal anode material respectively, and thus assembled into a cathode end plate, cathode plate, foamed iron-nickel, asbestos, foamed iron-nickel, anode plate and An electrolyzer with no current collector and no proton exchange membrane self-supporting electrode with components such as anode end plate, the schematic diagram of component disassembly is as follows figure 2 shown. A reaction device for hydrogen production and oxygen production by electrolysis of water according to the present invention comprises the above-mentioned electrolytic cell without a current collector and without a proton exchange membrane self-supporting electrode, and two sets of gas-liquid separators (used to separate hydrogen and lye and oxygen and lye), two sets of drying tubes (for drying hydrogen and oxygen respectively), lye tank, hydrogen storage tank, o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com